Suzhou Meirui: Focus on aluminum-magnesium alloy forming, ranking among the designated suppliers of many brand OEMs

Abstract:

Suzhou Meirui: Focus on aluminum-magnesium alloy forming, ranking among the designated suppliers of many brand OEMs

Established in September 2016, it is a diversified enterprise engaged in the production of aluminum-magnesium alloy, aluminum alloy and zinc alloy die-casting parts. It is a professional manufacturer integrating die-casting mold design, production and post-processing. Among them, aluminum-magnesium alloy is used mainly; aluminum and zinc alloy die castings are supplemented. It mainly produces aluminum-magnesium alloy die-casting parts, supplemented by aluminum and zinc alloy die-casting parts.

In the past 3 years, the founding team led by founder Wang Yang has created this startup company to develop products in seven major fields such as 3C consumer electronics components, communication products accessories, electrical locomotive parts, auto parts, smart projection opt mechanics parts, power tool parts, medical parts. It has become part of the supply chain of companies such as Lenovo, Weimeng, Audi, BMW, Mitsubishi and Changhong. It has grown from an annual output value of 8 million yuan (approx. USD 1.2 million) in 2017 to 60 million yuan (approx. USD 8.8 million) this year. At present, Meirui has purchased 9 sets of die-casting machines from Yizumi, and it is estimated that the output value in 2020 will exceed 100 million yuan (approx. USD 14.7 million).

3C field: among the designated suppliers of several computer factories

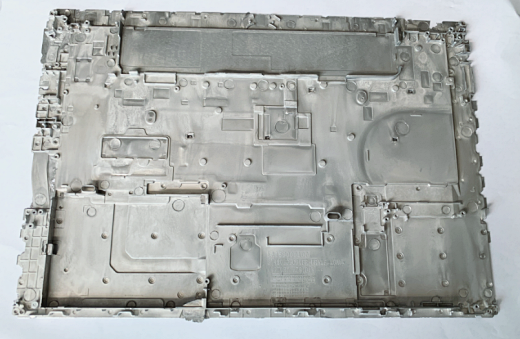

The third and fourth quarters of each year is the peak season for the production of notebook computer parts. They purchased the DM500H, DM650H and DM800H die-casting machines in advance, and applied magnesium alloy die-casting technology to produce A, B, C , D castings.

DM650H、DM800H

Under the premise of keeping the configuration unchanged, the appearance of magnesium alloy makes the notebook lighter and more textured. Wang Yang, general manager of Suzhou Meirui said: "The production of this aluminum-magnesium alloy notebook computer accessories, the pursuit of thin wall-thickness and molding efficiency, taking the 13-inch notebook computer C part as an example, its thinnest is only 0.6mm, the gap cannot exceed 0.05mm. The actual injection speed of the Yizumi cold chamber die casting machine reaches 5m/s, and with excellent clamping system technology and machine stability, it can meet the demand of high quality die castings. In addition, we purchased the H series die casting machine for its production efficiency can be increased by 15%-20%, and the molding cycle is shorter. ” At present, the molding cycle of this notebook computer C board can reach 30 seconds / piece, can produce more than 2,000 pieces per day, the output of one die casting machine can reach 750,000 pieces per year, and the pass rate is maintained at 95%. Due to the stability of its product quality and the continuous improvement of production efficiency, Meirui has become the designated supplier of many notebook computer manufacturers, and has also produced parts for the Weimeng computer, which is the leading company of global gaming notebooks.

Laptop parts

"Our workshops are all machines of YIZUMI. From the date of the establishment of our company, we have purchased YIZUMI die-casting machines and have bought 9 sets so far. Our die-casting parts require high precision. It is guaranteed from the aspects of quality, technology and after-sales service.” Wang Yang, general manager of Suzhou Ruimei commented.

Wang Yang, general manager of Suzhou Ruimei

Rapid development attracts attention, industry elite joins

The rapid development of Meirui has attracted the attention of industry giants. In 2019, listed company Guotong Industrial, and the venture capital company Longchuang Investment became direct partners of Meirui, laying a solid foundation for the take-off of the business.

Set up a R&D team, dare to get involved in new fields

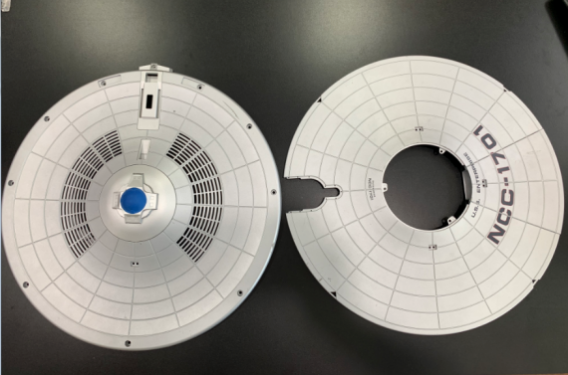

With the advent of the 5G era, communication technology is changing with each passing day, forcing the die-casting industry to continuously carry out technological innovation. "Innovation must be supported by R&D strength. We have more than 60 excellent technicians, all of whom are elites in the die-casting industry for more than 10 years. This year we will establish a research and development department to focus on the research and development of magnesium alloy molding," said Wang Yang. With the support of talents, Meirui also began to plan the layout of 5G communication equipment. Among them, the manufacturer of the Korean communication equipment, the production of the pre-research 5G filter, is being completed by the Yizumi DM800H die casting machine.

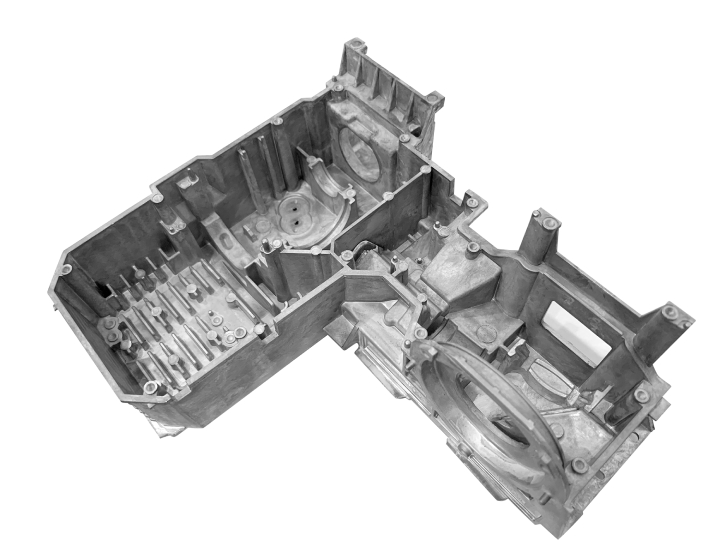

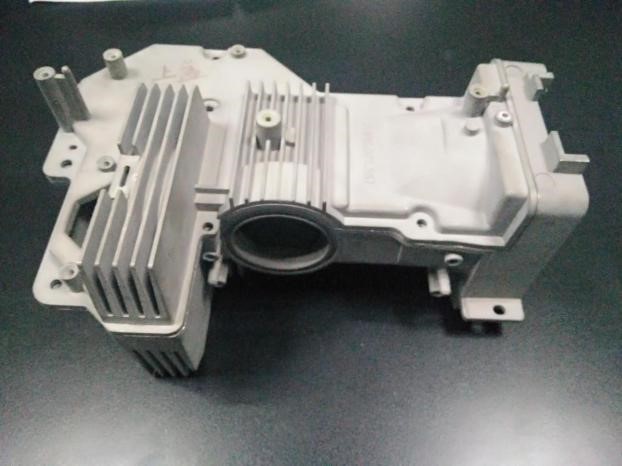

In addition, in the field of lightweight automotive parts and projection light machines, Meirui has been involved in the production of controller housings, display backplanes, central control brackets, etc. for Audi, BMW, Tesla and other supporting manufacturers, and Lenovo supporting manufacturers, Sichuan Changhong and other well-known enterprises to produce high-precision die-casting parts. Wang Yang said: "There are high requirements for the precision of die-casting parts in these fields. We hope to continue to work together with Yizumi to jointly develop and comprehensively improve the competitiveness in the market of advanced metal forming solutions."

Intelligent projection illuminator bracket and housing

Audi controller housing