Millison: A Global Leader in Die Casting Field--It has established strategic partnership with the World Top 500 Enterprises like Ericsson, PSA Peugeot Citroen, Tesla, etc.

Abstract:

Millison: A Global Leader in Die Casting Field--It has established strategic partnership with the World Top 500 Enterprises like Ericsson, PSA Peugeot Citroen, Tesla, etc.

When we talk about Millison Die Casting, it is undoubtedly belong to top “seed”enterprise in China die casting parts industry.

Since its inception in 2001, Chongqing Dajiang Millison Die Casting Co., Ltd (herein after referred to as “Millison DieCasting”) has been leveraging on technologies and innovation to drive its development. From the design of small bracket to the R&D of high precision automobile engine cylinder casing,Millison Die Casting has been constantly moving in the forefront of the industry with excellent products. Besides, its businesses have leapt to other fields like telecommunication, generators and electromechanical machines from automobile, pushing its development with diversity. As of now, it has established strategic working partnerships with many World and China Top 500 Enterprises such as Ericsson, PSA Peugeot Citroen,Changan Ford, Changan Suzuki, Deutz AG, etc.

Millison Die Casting always focus on connecting seamlessly with the international community with the latest technology in die casting, creating a world-class standard for the China die casting industry.

AutomobileField: Manufacturing Tesla car parts

In the achievements of Millison Die Casting, the area that stands out is definitely in the automobile field. In a long term, Millison Die Casting has been specializing in the manufacturing of automobile engine cylinder body, automatic transmission, automobile structural parts, etc. In 2012, it set up a production base in Xiangyang, Hubei. The production base is primarily responsible for the mass production of engine cylinder body to supply to alot of renowned automobile enterprises, including Dongfeng Peugeot-Citroen,Volvo Cars, SAIC-GM, etc. Yizumi’s DM3500T has been put into service in the production base in Xiangyang.

Due to the excellent performance of several areas such as on-site management, improvements in workmanship, and so on, Millison Die Casting has consecutively been awarded the Changan FordQ1 Certifications in 2016 and 2017. To that end, Millison Die Casting Deputy CEO, Mr. He Mao said, “The automobile die casting parts are very concerned with quality control. From the workmanship layout, selection of equipment models, molds manufacturing to manufacturing technique, machining,etc., Millison Die Casting has invested a large amount of manpower and material resources to constantly improve and optimize its manufacturing processes.

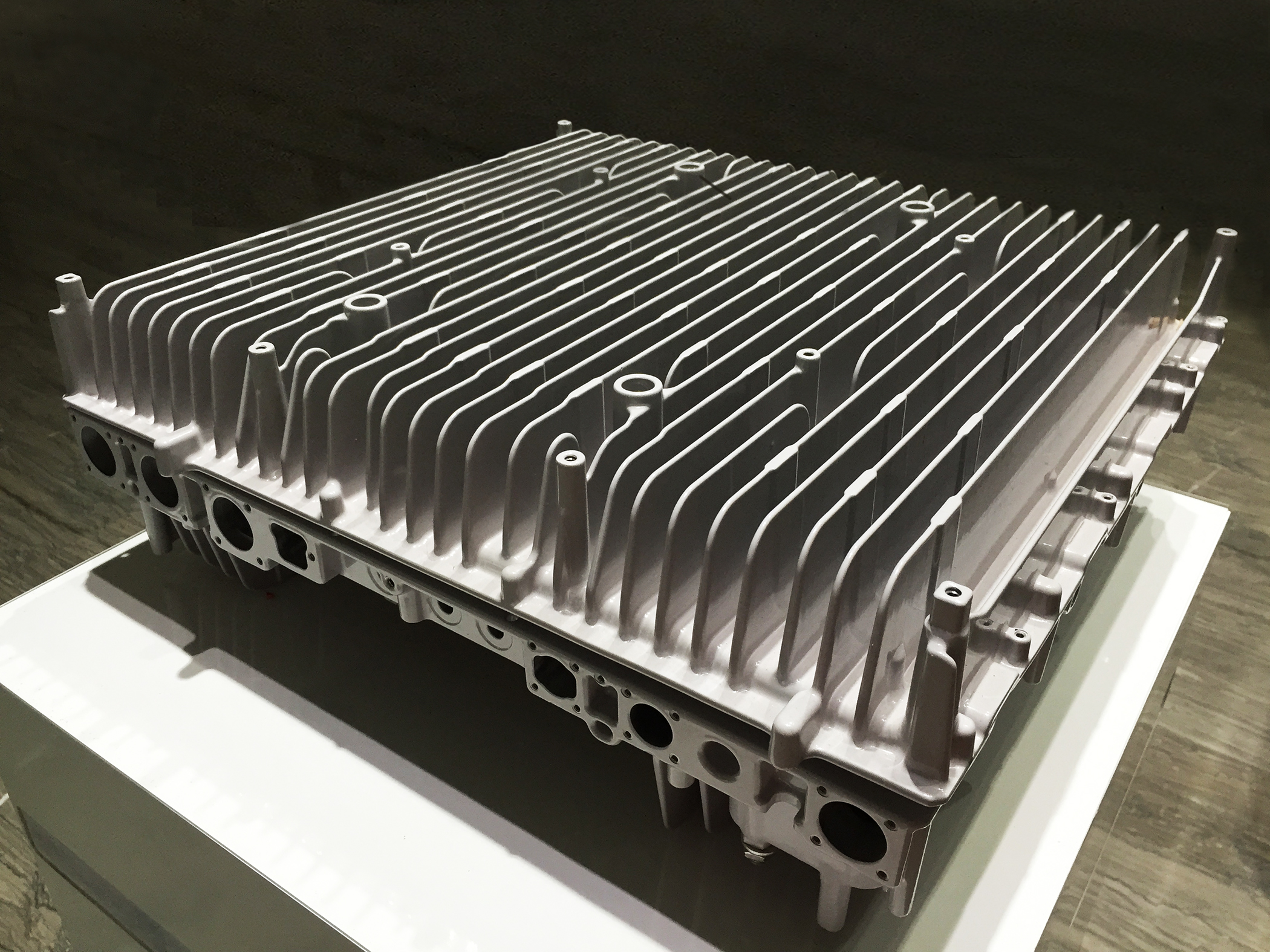

Apart from the continuous efforts in petrol cars, Millison Die Casting has been proactively investing in new energy vehicles. According to reliable sources, it has already been supplying various new energy vehicle parts like the gear box casing, battery tray, radiator, etc. to Tesla, Schaeffler, GM, and soon. “As the new energy vehicles are in the infant ascending phase, mass production has not yet to be achieved. However, it is the necessary mainstream trend in the automobile industry. Millison Die Casting has fully considered there quirements of such products, in particular the die casting technologies and the selection of equipment models,” Mr. He Mao cited.

Telecommunication Field: Strategic layoutof 5G products with Ericsson and Hua Wei

In 2005, Millison Die Casting has tiptoed into the telecommunication field. It has been recognized by an international heavyweight, Swedish Ericsson.

To achieve the radiation and lightweight effects of the products, Millison Die Casting has independently invented a new die casting technology involving thin radiators. It is able todie-cast radiators with 1.2mm thickness directly(the thickness of blades using traditional die casting technology is generally 2mm). The weight of the radiators has plunged nearly 40% as a result.Currently, the telecommunication products have steadily employed suchtechnology. Among them, a portion of the 4G base station filter casings are completed by Yizumi’s DM1650ARC real-time control die casting machine. In addition, it has also used Yizumi’s robotic automation systems facilitating many operating procedures like feeding, extraction, spraying, testing, etc.without using any manpower, thereby ensuring rapid delivery.

On top of that, Mr. He Mao cited that in the 5G projects, Millison Die Casting has successfully developed many related products and implemented batch production.

Yizumi has been rapidly developing in the last few years, especially in the die casting related automation field, it has had apparent improvements. Dajiang Millison has been laying out its intelligent factories. In time to come, I believe that we would have many more collaborative opportunities with Yizumi in the areas of automation as well as intelligent manufacturing.

----Chongqing Dajiang Millison Die Casting Co., Ltd. Deputy CEO, Mr. He Mao