Indoor LED lens first pass yield: 99.8%

Abstract:

Indoor LED lens first pass yield: 99.8%

The global LED industry is in the ascendant, and the trend of intelligent lighting is on the rise. Compared with traditional light sources, LED light sources are characterized by high luminous efficiency, easy control, long service life-time and low pollution. In recent years, the lighting industry is in the process of revolutionary upgrade. In 2016, the value of global LED lighting market has reached US$34.6 billion, an increase of 15.80%. The market growth rate remains high and the strong growth momentum is expected to continue.

Indoor LED lamps are the trend of the times. LED intelligent lighting allows the adjustment of light intensity and soft start of the lightand has other functions such as scene setting and timing control, which is more intelligent, safe, energy-saving, efficient and comfortable for the users.

In the LED intelligent lighting system, the control and driving parts are critical. At the same time, there are higher quality requirements for a series of plastic parts such as lenses, lampshades, lamp panels, light guide plates, etc. For example, the plastic lampshades and light guide plates are required to have uniform light transmission and higher accuracy of appearance and assembly.

However, with the increasing cost of raw materials, the influx of competitors, and higher demand in product quality, the competition in the LED lighting accessory market has become more intense. Some traditional lighting accessories companies are even facing the highest challenge ever. Yizumi FE series all electric injection molding machine is committed to providing efficient solutions for the indoor LED lighting industry, helping customers achieve iterative upgrade of their products.

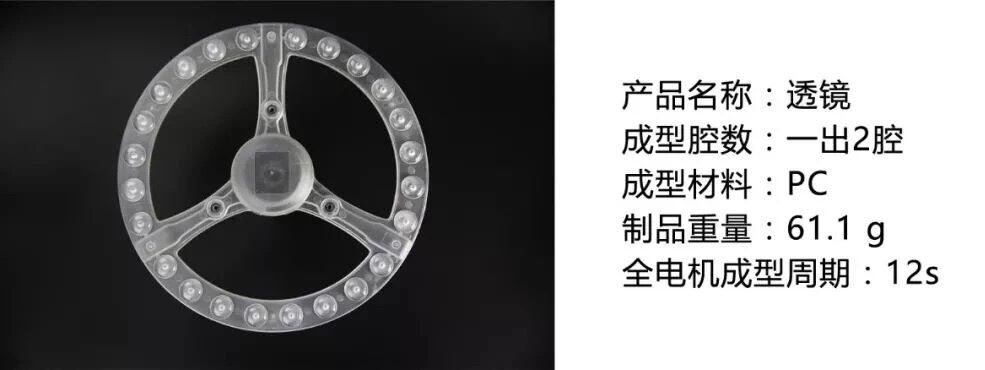

Customer Case: A LED lens manufacturer in Zhongshan

Product requirements:

1. The products are made of PC. The reuse rate of the scrap is low. The customer pays great attention to the first pass yield.

2. The products are required to have high-quality appearance without shrinkage, bubbles, gas marks, black spots or defects on the part surface. Each LED has uniform light transmission.

3. The mounting dimensions should be highly accurate without warpage and deformation.

In the past, this manufacturer used traditional hydraulic injection molding machines to produce LED lens withabout 90% first pass yield and a large amount of scrap, causing stubbornly high material costs. At the same time, to ensure high-quality appearance of the product, the cycle time should be limited to 20 seconds, which impedes further improvement of the production capacity.To improve the production efficiency, the manufacturer changed its production plan and used an all-electric injection molding machine in Yizumi FE series instead.

In response to customer's product requirements and production conditions, Yizumi provides a specific solution of machine:

Model of injection molding machine: FE180-640h

▍Advantages of machine: The accuracy of injection, plasticizing, back pressure and mold opening and closing is at least 10 times higher than a hydraulic injection molding machine of the same size. The FE machine also has advantages over other all-electric competitors.

▍Precision molding: The deviation of the injection end position is ±0.03mmand the deviation of part weight is ±0.6g (1‰), which effectively guarantees the product quality and the long-term consistency of production.The first pass yield is improved from 90% to 99.8% and the material costs are effectively reduced. The machine is equipped with plasticizing barrel and screw dedicated to PC, which improves the plasticizing efficiency,makes plasticizing more steady and uniform and cause no bubbles and black spots on the product surface.

▍Higher efficiency: The speed of the injection molding machine and the injectionaccuracy are stable. The parallel movements and coordination with the mold make the high-speed injection faster and low-speed injection steadier. The speed is increased by 200% and the cycle time is reduced from20 seconds to 12-15 seconds. The production efficiency is increased by 25%-40%.

The customer was very satisfied with the use of Yizumi FE series all electric injection molding machine, as it improved product quality, reduced production cost and shortened lead time. The customer also said that they would have more cooperation with Yizumi in the future.

Remarks:

1. Production pass rate: 99.8% is realized under the premise that the mold and production environment meet the requirements.

2. The above machine data are generated under the factory test and inspection standards.