LSR Liquid Silicone Injection Molding Machine: achieve flexible production

Abstract:

LSR Liquid Silicone Injection Molding Machine: achieve flexible production

As a non-toxic, heat-resistant, highly restorable thermosetting material, liquid silicone (LSR) has been in growing demand in the market in recent years. LSR is safe and environmentally friendly with its ability to fully meet the requirements of food safety, and its advantages of high- temperature resistance, low-temperature resistance, electrical insulation, tear resistance and weather resistance. Currently, LSR is mainly used in the fields of infants’ goods and medical and electronic products, such as baby bottle nipple, medical respirator mask, cell phone cases and watch bands, etc.

Liquid Silicone Street Light Lens

About LSR Liquid Silicone Injection Molding

Liquid silicone injection molding uses a two-part material delivery system which consists of an A component and a B component with a 1:1 ratio controlled by a quantitative device. After feeding the materials fully blended through the static blender into the barrel, they will be injected for molding production, heated in the mold for vulcanization and solidification.

The production cost of liquid silicone injection molding is relatively higher due to the high cost of liquid silicon materials, the cured products cannot be recycled, and the molding process needs to be equipped with a liquid silicone feeder, an injection molding machine for the modified material tube group as well as a special heating mold and a high-temperature controller.

Liquid Silicone feeder

Yizumi LSR Liquid Silicone Injection Molding Machine

To provide the best cost-effective LSR solutions with higher investment return, Yizumi introduced the liquid silicone injection molding machine in the market. Compared with the general transforming injection molding machine, our LSR machine can adapt to the production of more different sizes of silicone products and improve product yield and safety protection.

Flexible Production, Wide Application

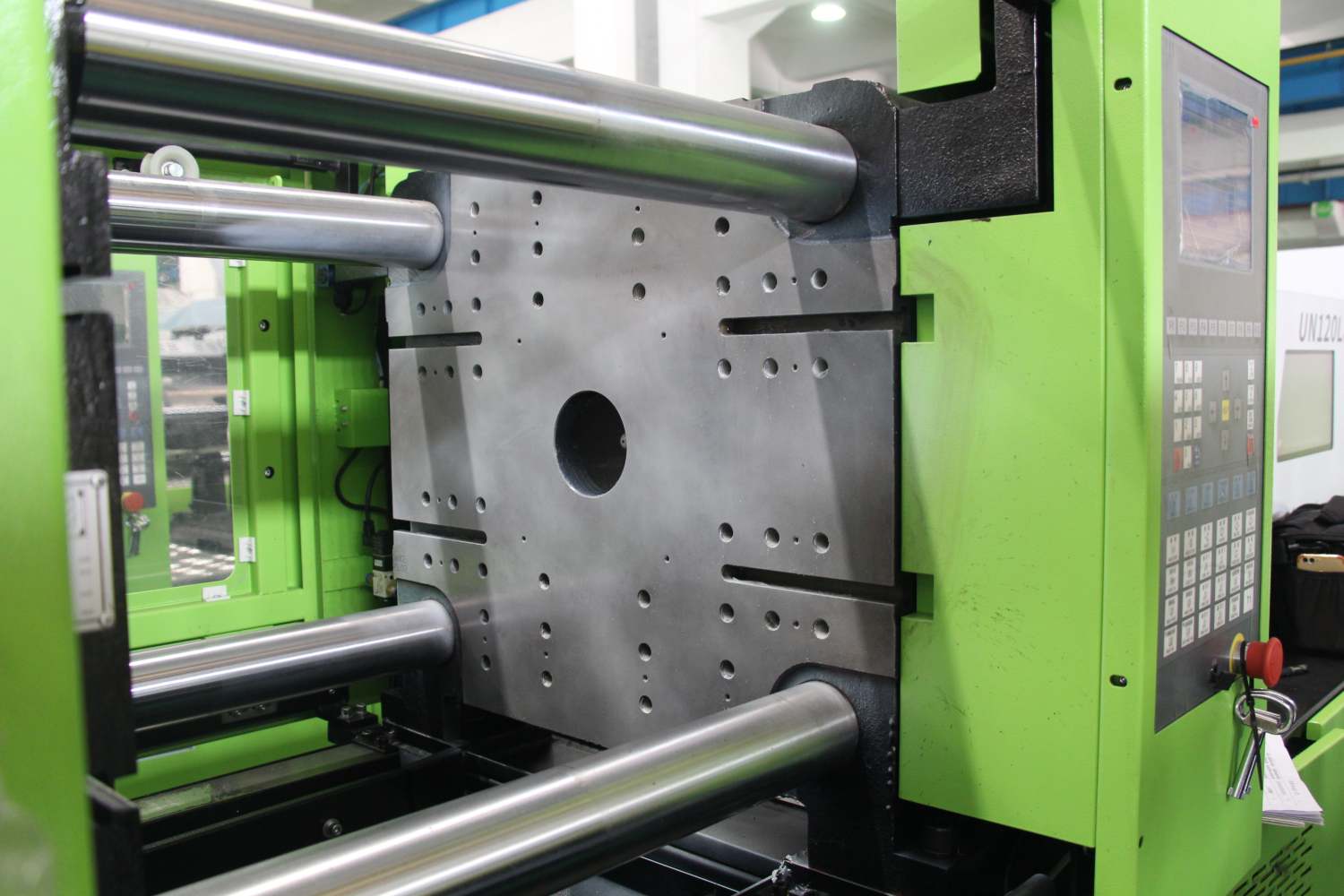

For Yizumi LRS injection molding machine, tie bar space is increased to 460, suitable for larger mold and convenient for customers to design and produce silicone products of different sizes and types, so as to improve machine utilization rate to a greater extent and reduce equipment investment cost.

Adapt to different sizes of liquid silicon products (liquid silicon cupping)

Improve product repeatability and product quality

Due to the low viscosity of the silicone raw material and the potential to leak, Yizumi LSR machine adopts special silicone plasticizing components.

The water-cooled thermostatic material barrel keeps the temperature accurately controlled, which can avoid the cross-linking curing reaction of silicon advance

Water-cooled pneumatic injection nozzle – prevents liquid silicone leakage, and prevents the mold temperature from being transmitted to nozzle and resulting in curing reaction of mixed LSR in the nozzle

Mixing screw for silicone to ensure the fully blending of components A and B and prevent silicon leakage which can improve the repeatability and performance of the product

Unique design of three parts that can ensure the precision during injection and pressure holding process

Vacuum pumping setting and interface: The use of vacuum mold improves the gas discharge effect of the mold and prevents defects such as short shot and gas burn caused by air traps

Add seal ring and wear ring at the tail end of screw to prevent silicone leakage at the rear end, material waste, and instability of injection

User-friendly Operation

The air gun fittings is reserved on the operating side, and the pneumatic fitting of the liquid silicone feeder is also reserved for quick connection

Visualized built-in mold temperature control to facilitate temperature adjusting; Separate connecting socket for each set of heating unit for the convenience of customers

Specialized silicon protection device to eliminate product contamination and enabler easy cleaning.