【Customer Story】Ningbo Xingyuan Machinery: Innovative Lightweight Solution for Magnesium Alloy Product

Abstract:

【Customer Story】Ningbo Xingyuan Machinery: Innovative Lightweight Solution for Magnesium Alloy Product

Lightweight is an endless journey. Where the cost allows, it is always a desire of the auto industry to use something with similar rigidity but lighter in weight to replace the original materials. In addition to the aluminum alloy, the major auto makers are now looking at magnesium alloy. The density of the magnesium is about two-thirds of aluminum. If a car uses magnesium alloy, the weight can be reduced by 30%. Magnesium alloy is also characterized by good impact absorption, casting, and cutting properties. The application range of magnesium alloy is quite comparable with aluminum alloy as more and more enterprises are now investing in this new material. Ningbo Sinyuan ZM Technology Co., Ltd is one of them.

Xingyuan isheadquartered in the “Townof Die Casting Tooling in China” -- Beilun, Ningbo.Originally started in aluminum and magnesium die casting tooling business, itnow focuses on providing innovative magnesium alloy lightweight solutions foraluminum alloy, plastic, and other composite auto parts. Product range includesauto lamp bucket, radiator case frame, armrest,gearbox, clutch, generator, etc., serving many renowned brands such as FAW,Ford, Audi, and Tesla.

Leadthe market with innovative product design

Today, the demand forautomotive magnesium alloy is growing strongly. While the new energy vehicleshave the urgent needs for weight reduction, the magnesium alloy applicationsbecome especially hot. For instance, GM’sinterior door panels, engine mounting bracket, and auto body panels usemagnesium alloy. Anotherfamous car manufacturer Changan, their new energyvehicles are also expected to use magnesium alloy for the steering wheelsupport and seat frames.

“Inthe past, China’smagnesium alloy die casting technology was not mature. It had to gone throughthe process to solve technical issue before replacing aluminum alloy. Now, the technology, equipment, and toolingare relatively mature and it is the time to experience the explosive growth.”said Mr. Wang Hongping, Deputy Managing Director of the company. Aimingat this window period, Ningbo Xingyuan took the initiative toparticipate in the early stage of product development with tier one auto partssuppliers such as Gelamo and Mahle for innovative product designs.

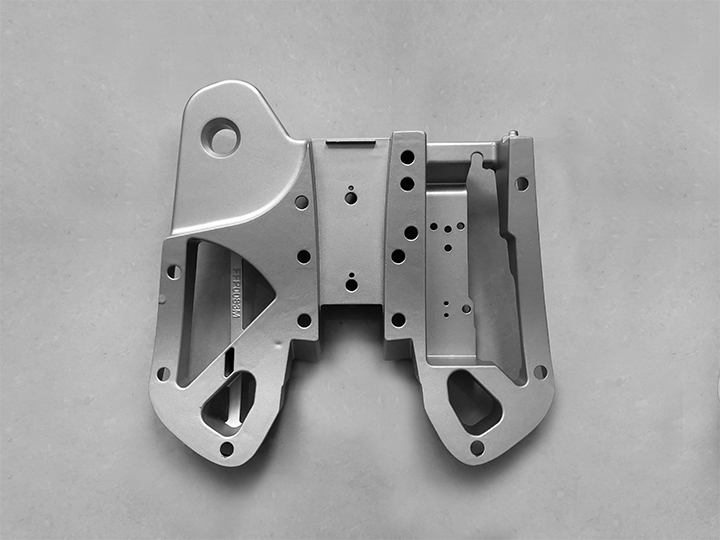

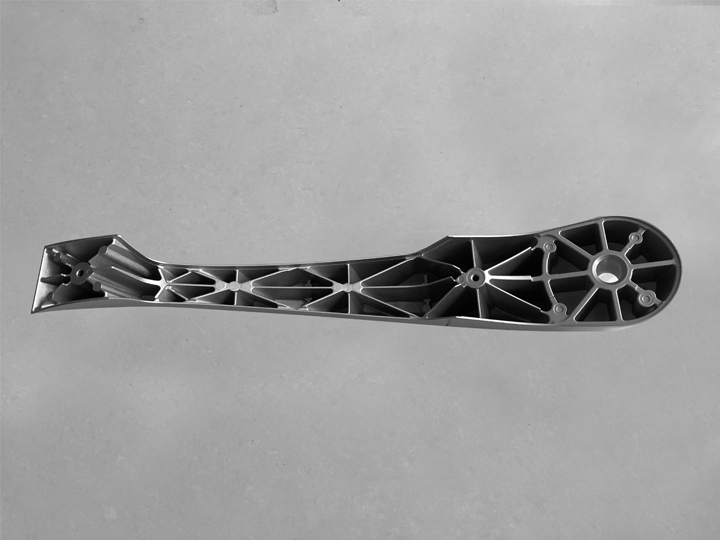

This is the company’snew development idea - lead the market, rather than being led by the market. “Before,we only processed according to the drawing that came with the order. Now, wetend to take the initiative to redesign products for customers.” Mr. WangHongping said that in addition to replacing aluminum alloy products withmagnesium alloy, a greater advantage of Xingyuan is to design an auto partconsisting of plastic, iron, and aluminum alloy to be a single castingmagnesium alloy part. For example, the recently introduced Ford lamp bracketwas originally made of a combination of aluminum alloy, plastic, and magnesiumalloy. The magnesium die casting solution proposed by Ningbo Xingyuan not onlyreduces the weight by 1/4, but also can cast it in a single step process. Itsaves the costs of materials and assembly while improving theproductivity.

Investingin large magnesium alloy die casting project

Thanks to theinnovative magnesium alloy products design capability, Xingyuan’sbusiness has kept a 30% high-growth rate in recent years. Solutions for newproducts include the headlight bracket for Tesla Model S, the headlight bracketand blower impellers for Chrysler’sDodge Charger, seat frame with armrest for Audi A4, and will be extended tolarger magnesium alloy casting.

Mr. Wang Hongping said thatcurrently not only more and bigger auto parts are made of magnesium alloy; theapplication is also extended to the structural parts and has the trend to bethinner. As a result, Xingyuan pro-activelyincreases purchasing of large tonnage die-castingequipment and has purchased HPM2000T die-casting machine and several sets ofYizumi 1000T, 800T die-casting machines. In the meantime, it also invested about USD 45.75 million in theconstruction of a new facility to expand its annual output of lightweight and environmentallyfriendly high-strength precision magnesium alloy die casting parts to 4.8million sets and tooling 50 sets. Another USD 3.44 million will be invested to build a R&D center dedicated to thedevelopment of high-strength precision magnesium alloy die-casting designingtechnology, tooling technology, and die-casting technology.

“Ningbo Xingyuan has always beenworking closely with Yizumi. Yizumi can respond to our needs quickly. Themachine performance is also among the best in China. As to the magnesium alloyproducts, because of the faster solidification properties of magnesium alloy,we pay special attention to the shot speed. The shot speed of Yizumi’sdie-casting machine can achieve 8m/s, allowing quick casting of products. Themachine performance is also quite stable which ensures the quality and productivityof the magnesium alloy products.”

—Wang Hongping, DeputyManaging Director ofNingbo Xingyuan