Connecting technology between China and Europe, YIZUMI Thixomolding Machines are now welcomed in China, Germany and American Market

Abstract:

Connecting technology between China and Europe, YIZUMI Thixomolding Machines are now welcomed in China, Germany and American Market

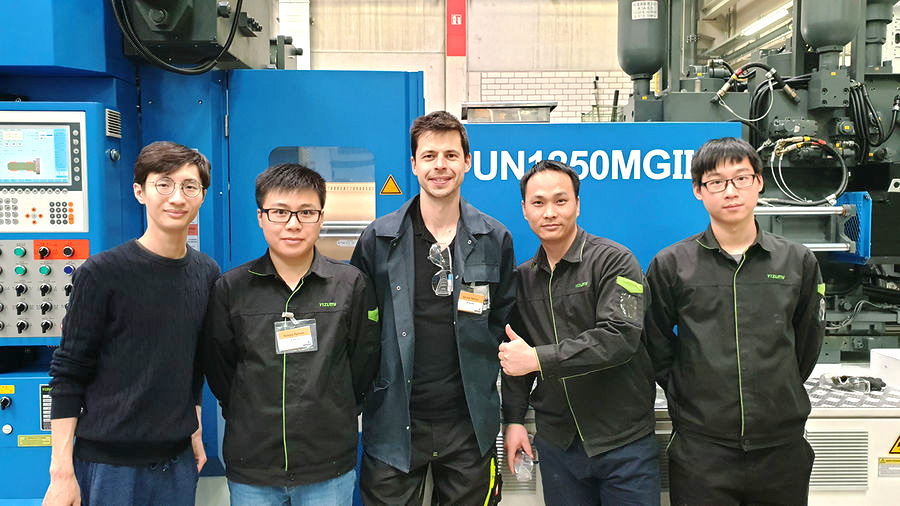

After successfully production performance test on first unit of YIZUMI 1250T Thixomolding Magnesium machine at HETTICH Germany. HETTICH had confirmed purchased additional two more units of UN1250MGII to integrate into their production facilities. At the same time, customers in China, Germany and America had also show great interest with application of YIZUMI Thixomolding machines for production of large lightweight design components.

Sui Tiejun, Product’s Manager responsible for YIZUMI Thixomolding project, comments that: “YIZUMI Thixomolding machine had consolidating the technologies within Germany and China. Level of Technologies for YIZUMI’s Thixomolding machine has been improved. We are confident its performance has reached the state of art Thixomolding Technologies.

Long-term Strategic Collaboration Partnership with Customers

Jointly development by YIZUMI China Headquarter and YIZUMI Germany R & D Center, UN1250MGII with a large shot weight model, adopts the advantaged European hot drop technology. This not only result with increase of shot weight dramatically, but also improves the filling behavior and the overall part quality.

Sui Tiejun expressed that: “We hope we could assist to solve the problems of having only one supplier for the customers, reduce their cost of investment, and ensure every customer result with quick and successful return of investment.”

With understanding of the Philosophy & Strategy of YIZUMI Thixomolding technology, Molded Magnesium Products, LLC. an American company, which main business includes magnesium light weight parts for automotive, aerospace, electronics, LED Lighting and medical care, are now also established as strategic partner with YIZUMI and confirmed purchase of one unit UN1250MGII machine recently.

Chinese customer Wuxi LANGSHION Lightweight Technology Co., Ltd., a well-established leader in lightweight metal design had purchased 1 unit of UN650MGII. At present, several performance tests have been arranged, performance of machine has passed through the acceptance test, now is in process of steady production. Sui introduced that LANGSHION is one of the strategic partners with YIZUMI in both die casting and Thixomolding technology. By introducing larger injection screw, shot weight and product’s quality has been improved. UN650MGII obtains positive feedback from the customers.

Next, during the recent 2020 CHINA DIECASTING fair in July, Taishan China Magnesium Technology Co., Ltd. signed up a contract with YIZUMI on site, confirm purchased two units of Thixomolding machines model UN650MGII & UN1250MGII. These machines, are planned to produce structural parts for drone, moving parts for bicycle, and prepared for the large-scale drone structural parts as well as new energy vehicle industry.

In addition to manufacturing enterprises, R&D institutes are also YIZUMI’s important strategic partners. Located in University of Kassel, Germany, the lightweight foundries technology and project engineering center GTK has been keeping close cooperation with YIZUMI. One unit of UN1250MGII will arrive at GTK in September 2020.

By collaborating with GTK, YIZUMI can further present its Thixomolding technology to European and global customers, “It will be the best show case. Besides, GTK is going to conduct many physical function and performance test on the machine, this will further improve level of technology of YIZUMI equipment.” Sui Tiejun said.

Customers with Quick Return of Investment