【Case】Changchun Faw United Casting Company The introduction of fully automatic die casting cell

Abstract:

【Case】Changchun Faw United Casting Company The introduction of fully automatic die casting cell

Changchun Faw United Casting Company (CFU) was established in 1995, which is an important production base for aluminum alloy castings of FAW Group Corporation and its subsidiaries. It mainly provids high-quality aluminum alloy casting for automotive, electronics and other industries. Its product line is including engine bearing bush cover, sprocket shell, engine support, all kinds of case, cover, etc. Furthermore, its customers are well-known enterprises at home and abroad, such as FAW Volkswagen, American Caterpillar, Shanghai Volkswagen, Faw Jiefang Automotive Company, Japan Komatsu, MOTOROLA, etc.

CFU and Yizumi has started cooperation since the beginning of 2011. Nowadays, there are more than 10 sets of Yizumi die casing machines running in the workshop of CFU, including ARC serial (Real Time Control) and Servo Motor serial die casting machine. Both sides have maintained friendly cooperated relationship over the years.

In the recent years, CFU has built up a plant in Chengdu, which has opened a new chapter for the cooperation between Yizumi and CFU.

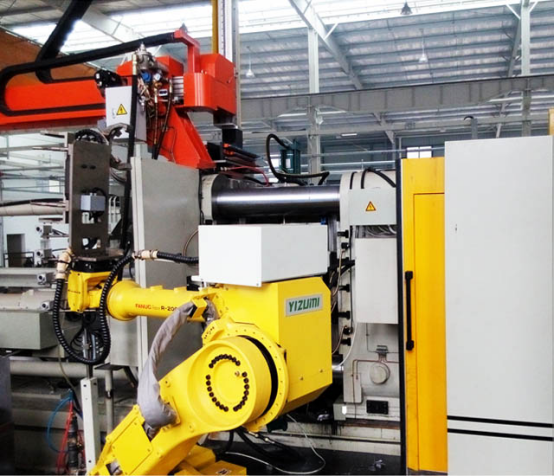

YIZUMI developed the first DM1250 fully automation system for CFU.

In October 2014, Chengdu Faw United Casting Factory came into used. It mainly provides parts for NCS and NF car model for FAW Volkswagen factory in Chengdu. At the moment of establishment, Chengdu Faw United Casting Factory has changed the traditional die-casting production management mode. They plan to adopt fully automatic die casting cell in order to improve the production efficiency.

Since it’s the first time they adopt fully automatic die casting cell, it’s a new and risky experiment for them to choose a cooperated die casting cell supplier. In view of the good cooperation between CFU and Yizumi, and the experience of purchasing Yizumi die casting machine of Chengdu Faw United Casting Factory, CFU offered a good opportunity to Yizumi robot automation division and dispatched core technical staffs to have business negotiation with Yizumi robot automation team.

“The core technical engineers of Yizumi have served for the die casting suppliers of TOYOTA, HONDA, NISSAN and other well-known enterprises. They have more than 10 years experience in die casing machine robot automation field, which bring us more confidence.” Mr.Wang Yongxin, the vice technical director of CFU said.

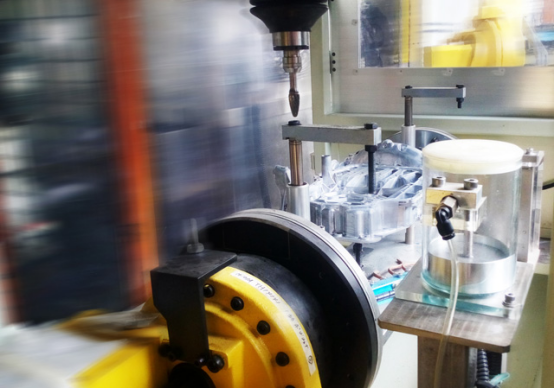

During the design of solution, Yizumi engineers had close communication with engineers and equipment operating personnels of Chengdu Faw United Casting Factory, studying details in the current production status and performance requirements of Chengdu Factory. Finally, according to the technical requirement of product, Yizumi had developed a solution which met customer’s requirement of fully automated production. They adopt Yizumi DM1250 die casting machine. The spraying procedure is adopted servo sprayer, rest procedure has realized fully automatic extracting, product integrity detecting, product cooling, trimming, fine-blanking, burnishing and product conveying by robot system.

The person in charge said, it’s difficult to realize fully automation of die casting cell. It not only requests superior performance of die casting machine, but also requests that each link of die casting cell from solution design to system control should be achieved excellence. The robot system was consist of casting type six axis Fanuc robot body, customized clamper for biscuit and product, personalized cooling, trimming and burnishing device, which can perfectly meet the technical requirement of product.

After the solution delivered successfully, now the die casting cell is running with stable and efficient average production tempo in Chengdu Faw United Casting Factory. Comparing with traditional die casting production mode, die casting cell can save labors of 5 workers. Fully automated production can not only improve the environment of die casting workshop, but also improve the qualified rate of the products, ensure the high quality of product.

Comprehensively promote the automation process

“Automated reform makes the quality of product under controller.” Mr. Wang Yongxin said. Take product trimming for example, manual operation may miss some links by mistake, while this will not happen by robot. It will strictly work accordance with program without any mistake, and position will ensure the trimming performance.

With the good layout and automation effect, The fully automatic die casting cell of Chengdu Faw United Casting Factory has became a model of fully automation upgrading in die casting industry. As a result, Yizumi has won the 2015 annual award for the best automatic system solution issued by Ministry of Industry and Information Technology in China.

Meanwhile, the successful example of Chengdu Faw United Casting Factory raised butterfly-effect on CFU. In order to comprehensively improve the automation degree, CFU has chosen Yizumi as the only supplier of automatic die casting cell, and carried on fully automation die casting cell upgrading for their existing 1250T/1600T/2000T/2700T and other tonnage die casting machines of different brand including Yizumi, LK, BUHLER, HPM, etc.

During the upgrading, Yizumi flexibly provided product cooling device, pneumatic hammer pressing device and other auxiliaries according to the actual production demand of CFU, and realized centralized process for the products and wastes from multiple die casting machines, which has furthest reduced the manual operation.

Now in the workshop of CFU, from ladling, spraying, extracting, burnishing to product and waste conveying procedure, the whole production line has realized fully automation. The dangerous and heavy works have been taken by robot. It has realized unmanned production in advance.