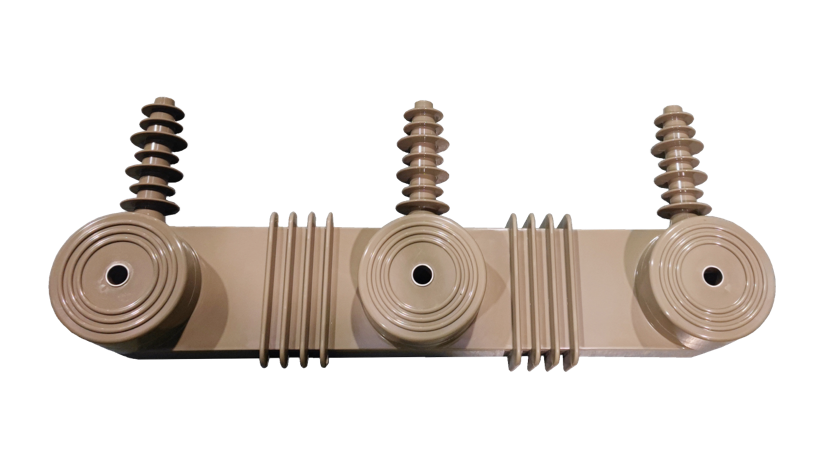

Total solution for different volatges composite insulators

We deeply understand the features of various parts and the needs of operators and managers. According to the properties of materials, and different process advantages, we create the most innovative and cost-effective solutions with lower investment and operation costs.

Application Highlights

Independent intellectual property rights

With ownership of multiple independent intellectual property rights.

Specialized plasticizing injection unit

Special plasticizing and injection unit for silicone, perfectly avoid air trapping and compound scorch.

Safety

Safe and easy silicone stuffer.

High rigidity clamping unit

Less flash at two sides even if the mold is very long.

Five clamping structures available

Five clamping structures available for realizing the best molding solution and the highest production efficiency.

Top brand hydraulic components

low energy consumption, easy to operate, and user-friendly.

Composite insulator Application

Product Video

Relevant Recommendation

We provide robot application and intelligent manufacturing overall solutions for industrial production processes of various industries, and strive to greatly reduce the production and operation costs of enterprises, improve production efficiency, and create greater value for enterprises.

Relevant Products

Relevant Technologies

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Application Highlights

Product Video

Relevant Recommendation

Service Process

Contact Us

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.