Lighter, more dimensionally stable and more economical components thanks to Foaming Frocess of Plastic

Abstract:

An introduction to the world of foam injection moulding After this blog article you will be foaming - no, not with anger, but with your injection moulding machine! Read what advantages foam injection moulding offers you, how it works and what coke has to do with it.

The foaming process of plastic, also known as foam injection moulding, offers numerous benefits including lighter components, improved dimensional stability, and cost-effectiveness. But how does it work? What are its advantages? After reading this article, you'll be eager to enhance your injection moulding operations with this innovative technique.

How does foam injection moulding work?

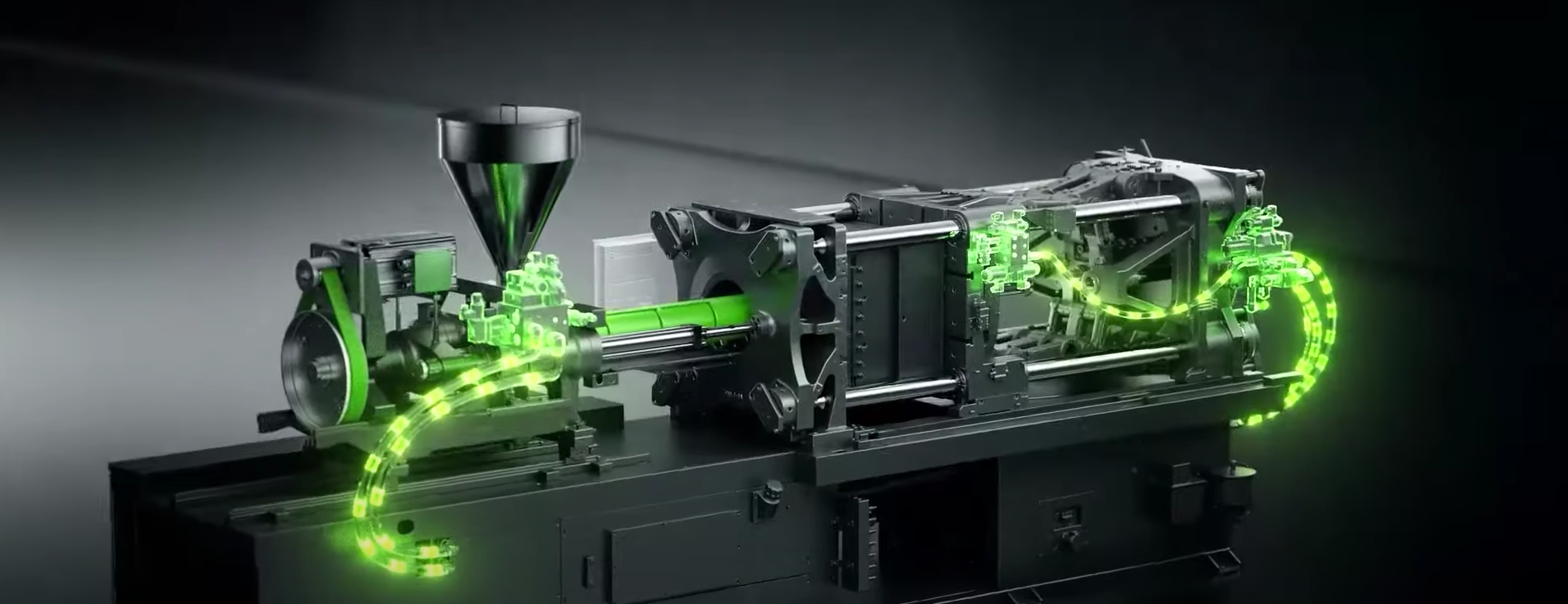

Foaming frocess of plastic is a sophisticated technological process used to manufacture components by injecting foam under low pressure into a mold. The injected material includes a blowing agent which, when heated within the mold, expands to fill its periphery. This injection of a foaming agent—typically a gas or chemical—during the moulding process creates a cellular structure as the material expands and subsequently cools. The outcome is lightweight plastic components that maintain essential structural integrity. The foam moulding technique allows for the addition or modification of various process parameters to achieve specific foam structures with distinct characteristics.

The foaming frocess of plastic initiates with the plastic material being melted and then combined with the foaming agent. This mixture is carefully injected into a mold cavity, where the controlled expansion of the foaming agent ensures consistent cell size and distribution throughout the material. This meticulous control results in a uniform and high-quality product suitable for a variety of applications.

What are the advantages of foaming plastics?

Weight Reduction

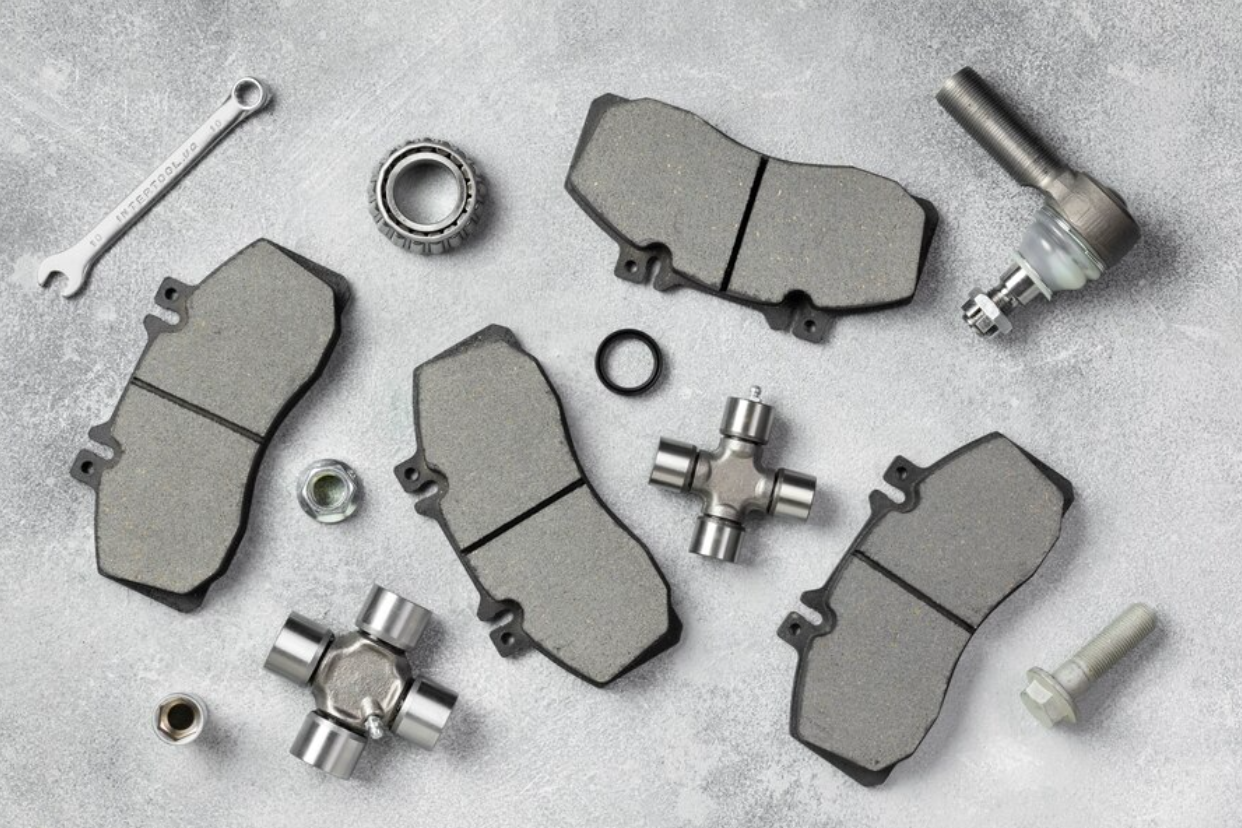

By introducing a cellular structure, foaming plastics significantly reduces the weight of the final component. This is particularly beneficial in industries where weight reduction is crucial, such as automotive and aerospace.

Material Savings

Foaming plastics uses less material to achieve the same volume as a solid part. This leads to cost savings in raw materials and a more sustainable manufacturing process.

Improved Dimensional Stability

Foamed plastics exhibit less shrinkage and warpage compared to solid plastics. This results in more dimensionally stable parts, which is essential for precise applications.

Enhanced Insulation Properties

The cellular structure created by foaming plastics provides excellent thermal and acoustic insulation, making it ideal for applications requiring such properties.

Surface Aesthetics

Foaming plastics can produce parts with a smoother surface finish, reducing the need for additional post-processing.

Foaming plastics offer several advantages over traditional solid injection moulding methods. The foaming process of plastic introduces a cellular structure that significantly reduces component weight, benefiting industries like automotive and aerospace. This process also saves material, promotes dimensional stability with less shrinkage and warpage, and provides superior thermal and acoustic insulation. Additionally, foaming plastics reduce cycle times, enhance productivity, and yield parts with smoother surface finishes, minimizing post-processing requirements. These benefits collectively contribute to cost efficiency, sustainability, and improved performance across diverse applications.

What types of foam injection moulding are there and what do I need for it?

Physical Foaming: This involves the use of gases such as nitrogen or carbon dioxide as the foaming agent. The gas is injected into the molten plastic, causing it to expand and form a cellular structure. Physical foaming is known for producing parts with uniform cell sizes and high strength.

Chemical Foaming: Chemical blowing agents are added to the plastic material. These agents decompose under heat, releasing gases that create the foamed structure. Chemical foaming is versatile and can be used with a wide range of plastics.

Structural Foam moulding: This process involves injecting a gas-charged molten plastic into a mold cavity. The gas expands the plastic, forming a cellular core with a solid outer skin. Structural foam moulding is ideal for large parts that require a high strength-to-weight ratio.

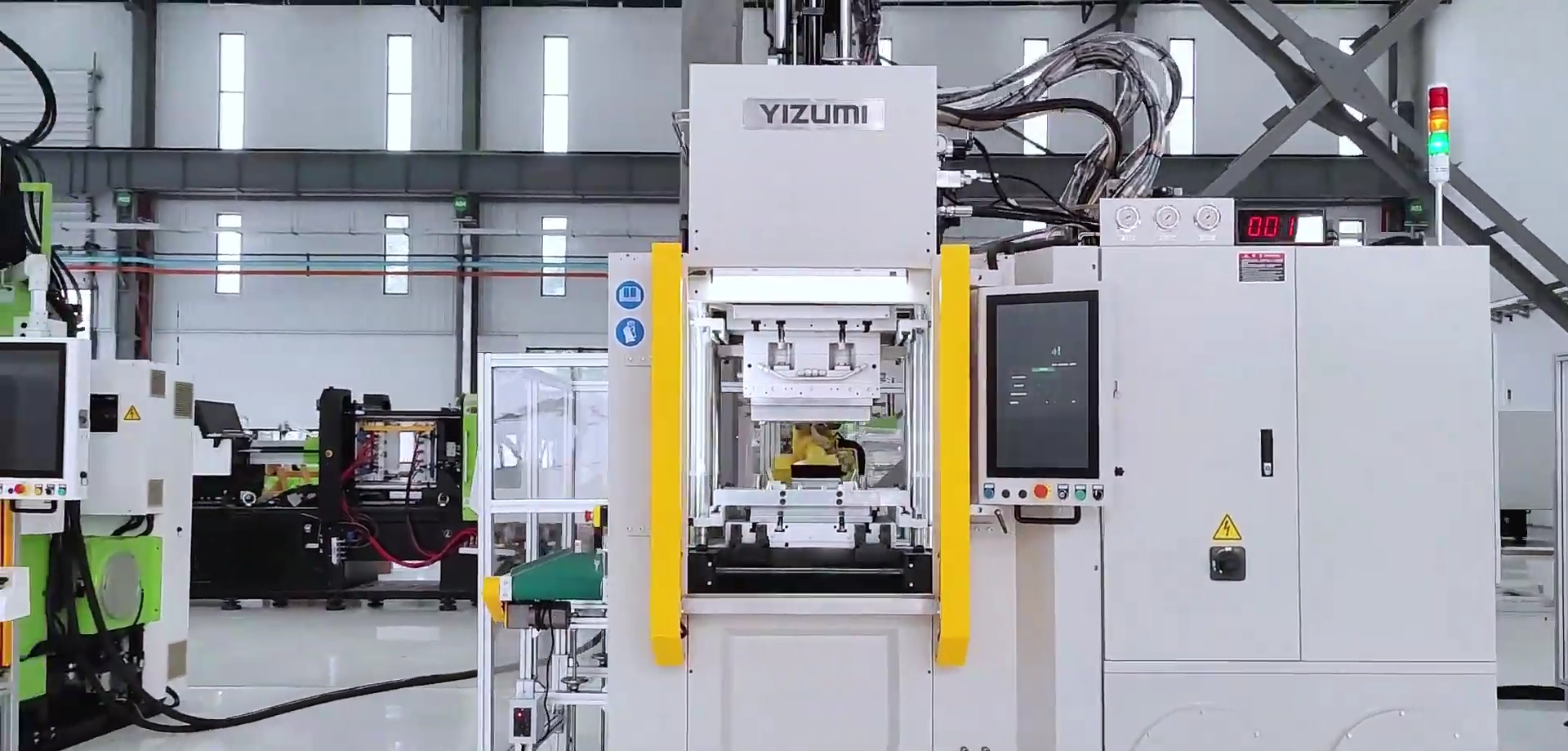

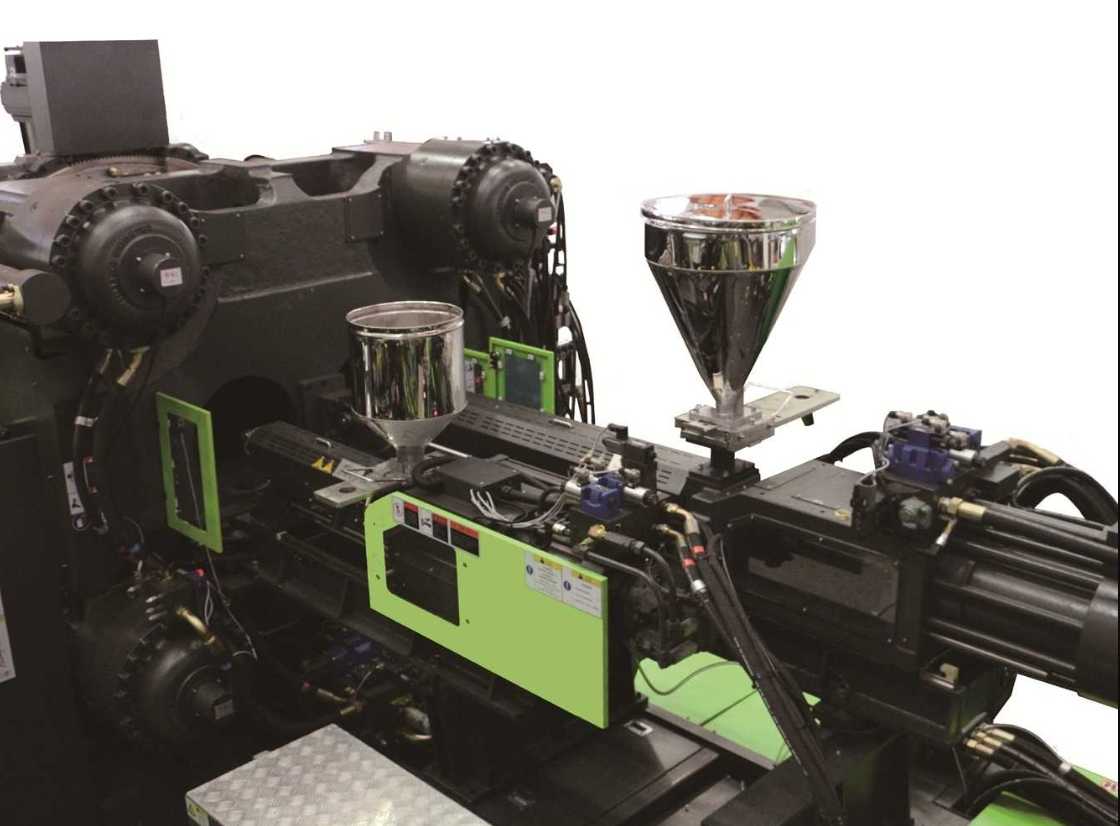

To successfully initiate the foaming process in plastic manufacturing, it is crucial to procure specialized equipment tailored for this purpose. This includes acquiring injection moulding machines equipped with foaming capabilities, as well as molds specifically designed to accommodate the expansion and moulding of foamed plastics. Moreover, integrating foaming agents into the manufacturing process is essential. These agents facilitate the formation of microcellular structures within the plastic, enhancing its properties such as density, thermal insulation, and acoustic performance. Last but not least, stringent attention must be paid to safety protocols and handling procedures when working with foaming agents, ensuring a secure operational environment. By meticulously implementing these components, manufacturers can effectively harness the advantages of foamed plastics in various applications.

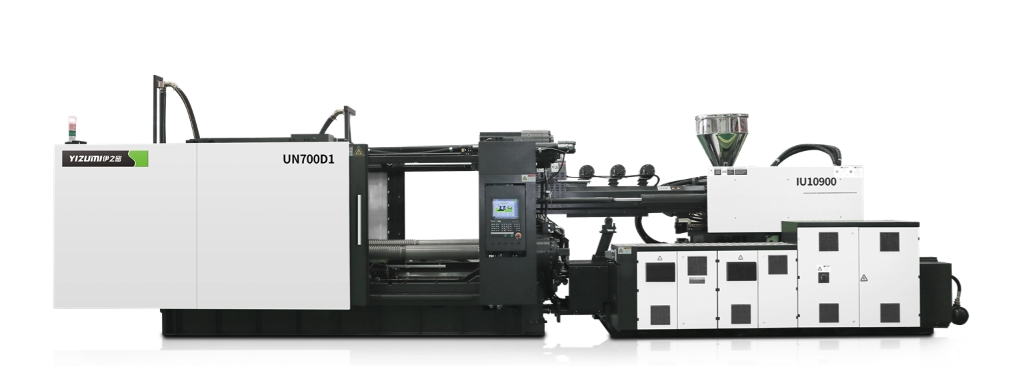

For superior results in foamed plastic manufacturing, consider YIZUMI's D1 Series Two-platen Injection molding Machine. Engineered with advanced capabilities for the foaming process of plastic, this equipment ensures precise control and optimal performance throughout production. With stable performance and high-quality products, YIZUMI brings customers higher value returns and is your best choice worthy of long-term trust.

Lighter components thanks to plastic foams - the most important facts at a glance

How the Foaming Process of Plastic Works: In the foaming process of plastic, a blowing agent (gas) is initially dissolved into the material. During injection, a rapid decrease in pressure occurs, facilitating the escape of the gas and initiating foaming within the material.

Advantages of Plastic Foaming: The foaming process of plastic offers several advantages. It is cost-effective, reduces cycle times due to uniform internal pressure within the mold cavity, and results in lighter-weight components.

Requirements for Plastic Foaming: To implement plastic foaming, you'll need a suitable blowing agent (gas) and optionally, additional equipment for its injection (physical foaming), or simply the blowing agent itself (chemical foaming). The process typically does not necessitate extensive additional equipment.

How can I find out more about foam injection moulding?

Feel free to reach out to our experts. We're here to offer comprehensive advice and collaborate with you on tailored solutions that meet your unique needs. YIZUMI stands out not only as a premier manufacturer of moulding equipment but also as a leading provider of complete solutions for foam injection moulding. By leveraging global expertise and diverse professional capabilities, we continuously innovate to address diverse market needs.

Our focus is on advancing technology, expanding product offerings, and ensuring global operational excellence. YIZUMI is committed to delivering advanced solutions in foam injection moulding, enhancing customer satisfaction, and solidifying our position as a world-class, respected enterprise known for its scale and influence in the industry.

Conclusion

With the capability to utilize the foaming process of plastics, manufacturers can achieve components that are not only lighter but also more dimensionally stable and cost-effective. This technological edge proves invaluable across diverse sectors, empowering businesses to enhance their competitive position. Understanding the intricacies of this process, appreciating its inherent advantages, and exploring the various methodologies of foam injection moulding are crucial steps toward unlocking its full potential for your specific applications.

So, prepare to embark on this journey of foaming—not in frustration, but with anticipation of the myriad possibilities that foam injection moulding offers! And remember, for all your foam injection moulding requirements, YIZUMI stands ready to provide comprehensive support at every stage of your project.