How to Estimate Injection Molding Cost?

Abstract:

Learn how to estimate injection molding costs with this detailed guide, covering mold injection manufacturer considerations, prototype injection molding, and key cost variables.

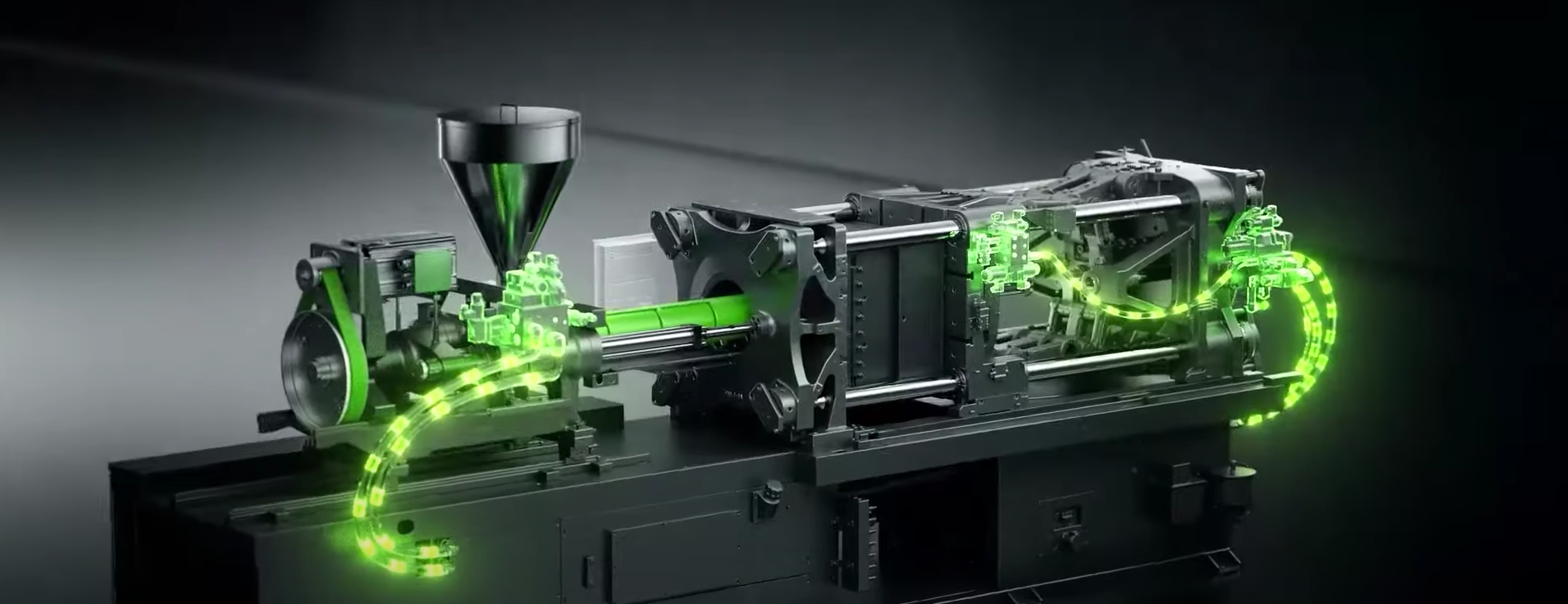

Estimating the cost of injection molding is crucial for manufacturers looking to optimize their processes and remain competitive. From prototype injection molding to mass production, understanding the cost breakdown can help businesses make more informed decisions. This guide will walk you through the types of costs involved in injection molding, how to calculate them, and how YIZUMI's Next-Gen A6 Series Advanced and Intelligent Injection Molding Machine can help reduce these costs while boosting efficiency.

Types of Costs in Injection Molding

The cost of injection molding can vary significantly depending on a variety of factors, from the complexity of the product to the machinery used. Below are the main cost categories involved:

Mold Design and Fabrication Costs:

The mold itself is one of the most expensive components of the injection molding process. Designing and manufacturing a mold involves selecting materials, creating prototypes, and optimizing the mold's performance. High-quality molds ensure precise and consistent production.

Material Costs:

The choice of material significantly impacts cost. Plastics, rubber, and specialized compounds each come with their own pricing structure, based on factors like availability, quality, and processing difficulty.

Machine Time and Labor Costs:

The time spent operating the injection molding machine and the labor required for setup, maintenance, and operation also contribute to the total cost. YIZUMI's A6 Series injection molding machines are designed to minimize downtime, enhancing productivity and reducing labor costs.

Energy Costs:

Injection molding is an energy-intensive process. The energy required to heat the material and operate the machine is a significant factor, but YIZUMI's A6 Series is equipped with a new energy-efficient hydraulic system that provides substantial energy savings of over 12%.

Post-Processing and Finishing Costs:

Once the mold has been injected and cured, further operations like trimming, painting, or assembly may be required. These steps increase the overall cost of manufacturing.

Injection Molding Cost Overview

The total cost of an injection molding project depends on several variables, including material, design complexity, labor, machine capabilities, and mold costs. Here's a breakdown of the cost elements:

Mold Cost: The cost of creating a mold can range from a few thousand dollars to over $100,000, depending on its complexity and material. More complex molds, particularly for prototype injection molding, may have higher initial costs but result in cost savings over time due to their durability and precision.

Material Cost: This is typically calculated based on the weight of material used per part, and it can fluctuate depending on the material type. For instance, thermoplastics may cost less than specialized rubbers like silicone or nitrile.

Machine Hour Cost: Machine time includes setup, cycle time, and any adjustments needed during production. The overall efficiency of the machine, such as that offered by the YIZUMI A6 Series, directly impacts the machine hour cost. With intelligent features like clamping force management and energy-efficient design, the A6 Series reduces overall cycle time and minimizes operational costs.

Labor Cost: Labor costs depend on the complexity of the operation and the level of automation in the process. YIZUMI's Next-Gen A6 Series machines reduce labor costs by incorporating advanced automation, reducing the need for constant human oversight and intervention.

Variables that Impact Injection Mold Cost

Several variables affect the final cost of injection molding. The following are critical factors that manufacturers must consider when estimating costs:

Product Complexity: More complex parts require more intricate molds, longer production times, and higher costs. If your part design includes multiple cavities or intricate details, it will require more advanced molds and higher precision.

Material Choice: The type of material used in the injection molding process plays a significant role in cost estimation. Common materials like ABS and polyethylene are generally less expensive than specialty materials like silicone or rubber.

Part Volume: The larger the production run, the lower the cost per part due to economies of scale. High-volume runs generally justify the higher initial costs of mold design and manufacturing.

Cycle Time: The length of time required to complete a cycle affects costs directly. A longer cycle time means more energy consumption, higher labor costs, and greater wear on the machine. The A6 Series has been optimized for quicker cycle times with features like intelligent clamping force management and efficient energy usage, which directly contribute to cost reductions.

Mold Life: Molds that wear out quickly need to be replaced more often, increasing costs. YIZUMI's A6 Series machines help to extend mold life through features like optimized clamping force and reduced wear, which results in fewer replacements and maintenance costs.

Injection Molding Cost Calculators

Many manufacturers now rely on injection molding cost calculators to estimate the costs associated with different projects. These calculators allow you to input parameters like:

· Material type and weight

· Part dimensions and complexity

· Mold design and quantity

· Machine time and labor costs

By inputting this data, the calculators can provide a cost estimate that helps businesses make informed decisions before committing to a project. YIZUMI's A6 Series can provide manufacturers with the flexibility to adapt to different materials and part designs, further optimizing the cost estimation process.

Reducing Injection Molding Costs

Reducing costs in injection molding requires strategic adjustments throughout the entire production process. Here are some effective strategies:

Improve Mold Design: Optimize mold designs to minimize material waste, reduce cycle time, and improve part consistency.

Automate the Process: Automation reduces labor costs, improves consistency, and speeds up production. YIZUMI's A6 Series is equipped with automation-friendly features, reducing the need for manual intervention.

Optimize Machine Settings: Machines that use intelligent technology, like the A6 Series, can reduce energy consumption and improve operational efficiency. The intelligent clamping force management system adjusts force dynamically to reduce stress on molds and machines, which lowers maintenance and operational costs.

Choose the Right Material: Use materials that meet the functional requirements of your product without being overly expensive. Using cost-effective materials can reduce your total cost without compromising quality.

Get Started With YIZUMI Injection Molding

If you're looking to take control of your injection molding costs while improving efficiency, consider upgrading your equipment with YIZUMI's Next-Gen A6 Series.

Key features of the A6 Series that help reduce molding costs include:

· Energy-efficient hydraulic systems that achieve over 12% savings.

· Intelligent clamping force management to optimize production and reduce stress on the mold.

· Fast cycle times thanks to advanced injection systems, ensuring high productivity.

By incorporating YIZUMI's A6 Series, manufacturers can not only lower production costs but also improve product quality and consistency, ensuring long-term success.

Conclusion

Estimating the cost of injection molding requires a deep understanding of various factors, including material costs, mold design, machine efficiency, and labor. With innovations like the Next-Gen A6 Series from YIZUMI, manufacturers can optimize every aspect of the injection molding process, from energy consumption to cycle time, helping to keep costs low while ensuring high-quality production. Whether you're working with a mold injection manufacturer or developing prototype injection molding parts, investing in cutting-edge machinery can significantly improve your bottom line.