Co-injection: Sequential injection molding for food packaging

Abstract:

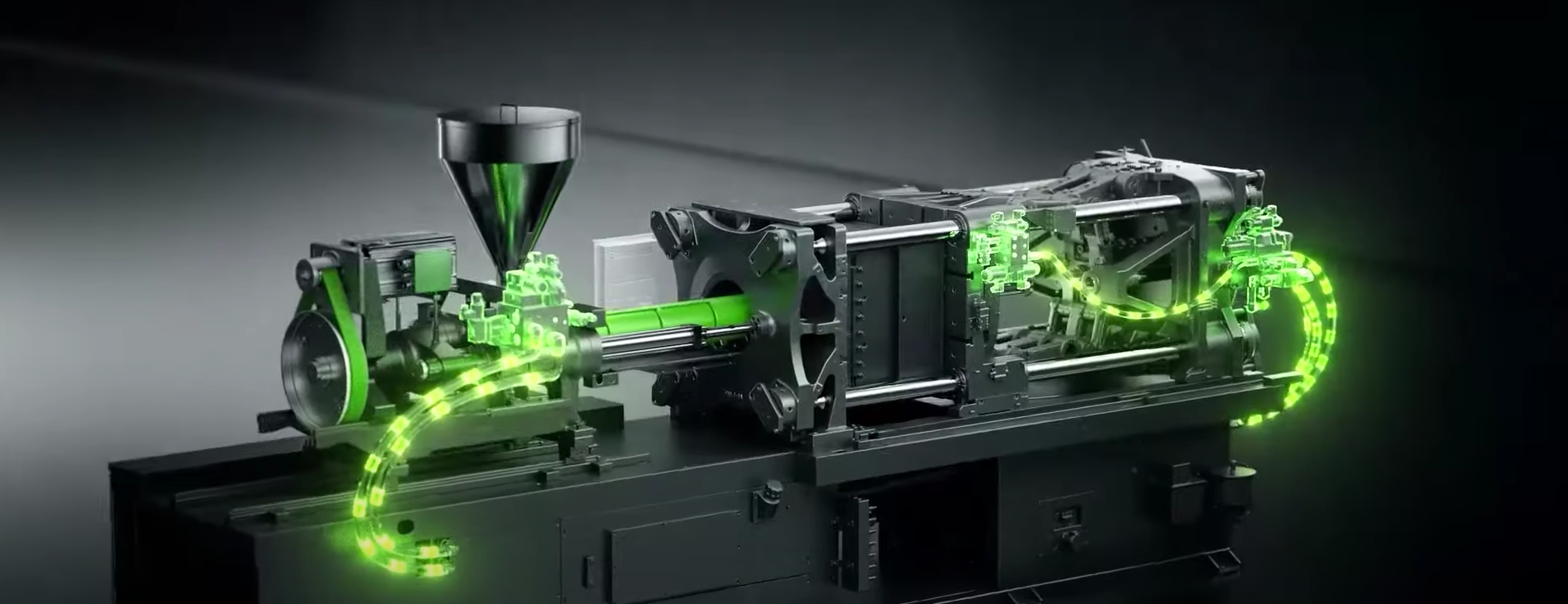

Types of sandwich injection molding - Functions & Applications. In short, in sandwich injection molding, two different materials are introduced into the mold cavity in such a way that a three-stage layer structure is achieved in the injection molded part in cross-section: skin component - core component - skin component. Through the intelligent combination of different materials, targeted improvements in the properties of the component can be achieved.

In the competitive world of manufacturing, particularly in the food packaging industry, innovation is key. One such innovation is sequential injection molding, a type of co-injection that allows for the creation of multi-layered structures within a single molded part. This process involves the introduction of two different materials into the mold cavity, resulting in a three-stage layer structure: skin component - core component - skin component. Through the intelligent combination of different materials, significant improvements in the properties of the component can be achieved. This article explores the advantages and applications of sequential injection molding, particularly in the context of food packaging.

What are the advantages of the sequential injection molding process co-injection?

Sequential injection molding offers several advantages that make it a preferred choice in various manufacturing sectors, such as automotive, electronics, and consumer goods. Its ability to precisely control material placement and sequence allows for the creation of complex, multi-material parts with enhanced quality and efficiency.

Material Efficiency: By leveraging a less expensive or recycled material for the core component and utilizing a high-quality material for the outer skin, manufacturers can effectively lower production costs without compromising the surface properties and appearance of the final part. This approach optimizes material usage, reduces waste, and enhances cost-effectiveness in manufacturing processes.

Enhanced Properties: Sequential injection molding enables the integration of different materials to enhance specific properties such as strength, flexibility, and thermal resistance within a single part. This capability is crucial in industries where products require varied performance attributes, allowing manufacturers to tailor materials accordingly and achieve optimal product functionality and durability.

Design Flexibility: The flexibility inherent in sequential injection molding empowers designers to create complex parts with intricate geometries and varying material characteristics. This method supports innovative product designs that meet diverse customer demands and specific application requirements. Designers can experiment with material combinations and configurations, optimizing performance and aesthetic appeal without compromising manufacturing efficiency.

Improved Aesthetics: Sequential injection molding excels in producing parts with high-quality surface finishes, which are essential for consumer-facing products where appearance plays a significant role. The process ensures uniform material distribution and precise control over surface texture and color, resulting in visually appealing products that meet stringent aesthetic standards and enhance brand perception.

Environmental Benefits: Utilizing recycled materials for the core component in sequential injection molding not only reduces material costs but also promotes sustainability by minimizing waste generation. By incorporating recycled content into manufacturing processes, companies can contribute to environmental conservation efforts and align with eco-friendly practices, thereby improving their corporate social responsibility profile and meeting regulatory requirements related to sustainable manufacturing practices.

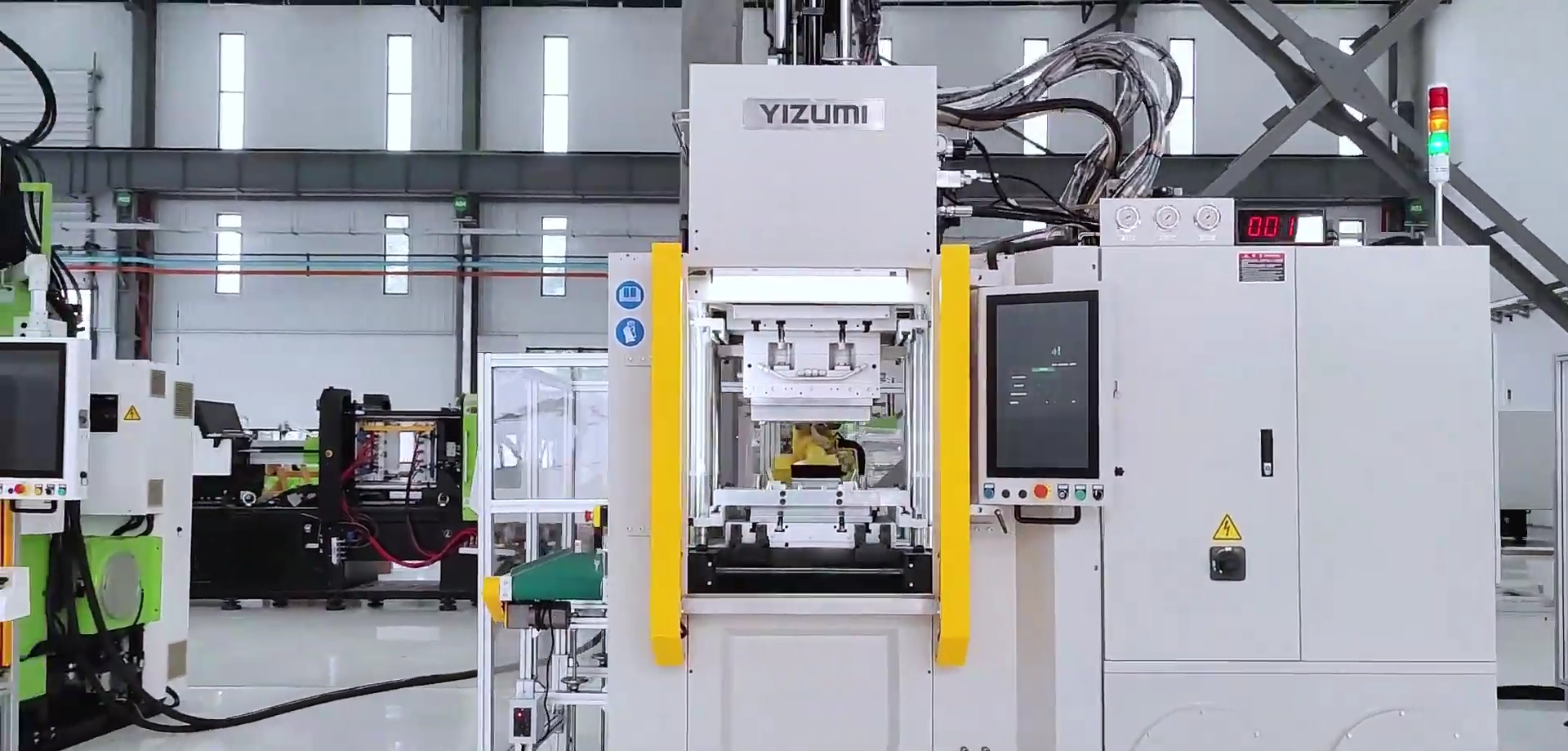

The multiple-shot table injection technology of YIZUMI, for example, adopts a long waist-shaped positioning ring for the fixed mold, which can be used to inject at the same time at any size station according to the demand, and when the multiple-shot mold is not used, any injection table can be used as a single-cylinder injection table to inject at the center, and on the basis of the original double-shot, an independent injection table can be added to the non-operating side or changed to a quadruple-shot on the basis of the double-shot. This technology has decisive advantages in the sequential injection molding process co-injection.

Why sequential injection molding for food packaging?

Sequential injection molding is particularly well-suited for the food packaging industry due to several compelling reasons. One of its standout advantages lies in its ability to create packaging with excellent barrier properties, crucial for preserving food freshness and extending shelf life. By strategically combining a cost-effective core material with a food-grade outer material, manufacturers can produce high-quality packaging solutions at a lower cost, without compromising on safety or functionality.

Furthermore, the process allows for extensive customization of packaging properties to meet specific requirements, such as heat resistance or transparency. This flexibility is essential for adapting to diverse food products and packaging needs in the market. Additionally, sequential injection molding ensures strict regulatory compliance by enabling the outer layer of packaging to meet stringent food contact material standards, while optimizing the core material for other desired properties.

Overall, sequential injection molding stands out in the food packaging industry for its ability to deliver packaging solutions that excel in barrier performance, cost-effectiveness, customization, and regulatory adherence. These qualities make it an ideal choice for manufacturers aiming to meet the rigorous demands of ensuring food safety, durability, and functional excellence.

What Are the Advantages of Sequential Injection Molding for Food Packaging?

Co-injection allows for cost-effective packaging solutions by utilizing cheaper plastics for the non-food-contact core, leveraging materials with higher density and stability to reduce wall thickness and overall material usage. This sequential sandwich process is especially advantageous in industries like packaging, where minimizing cycle time is crucial for economic efficiency. It simplifies setup and operation similar to traditional two-component methods, making it versatile for various applications. Explore the technology used in YIZUMI's Two-platen Multi-component Injection Molding Machine, and you'll have a whole new idea!

The applications of co-injection molding are highly diverse and hinge significantly on the selection of materials. For instance, the core material can serve multiple purposes such as acting as a barrier layer in food packaging, providing structural reinforcement, or achieving weight reduction. Utilizing recycled or foamed materials for the core is also a cost-effective strategy. Moreover, by alternately injecting differently colored variants of the same material, manufacturers can create striking marbling effects, enhancing the aesthetic appeal of the final product.

Does the sequential injection molding process co-injection also have disadvantages?

Yes, Co-injection molding technology offers numerous advantages but also comes with certain limitations. It involves a more complex process compared to traditional injection molding, necessitating specialized equipment and expertise. Initial costs for equipment and mold design can be higher, although these investments can be justified by long-term savings and efficiency improvements. Material compatibility is another challenge, as not all materials can be effectively combined for co-injection, requiring careful selection and testing. Additionally, managing two different materials can increase processing time, although ongoing technological advancements aim to enhance cycle times in co-injection processes.

Conclusion

Sequential injection molding, a type of co-injection, presents significant opportunities for innovation and efficiency in the manufacturing of food packaging. By combining different materials in a single molded part, manufacturers can achieve targeted improvements in product properties, enhance aesthetic appeal, and reduce costs. Despite some challenges, the benefits of sequential injection molding make it a valuable process for the food packaging industry. As technology advances, the process will continue to evolve, offering even greater possibilities for manufacturers looking to stay competitive in a dynamic market.

For manufacturers in the food packaging industry, understanding and leveraging the advantages of sequential injection molding can lead to significant improvements in product quality, cost-efficiency, and environmental sustainability. By partnering with experts like YIZUMI and investing in the right technology, companies can optimize their production processes and meet the growing demands of consumers and regulators alike. To learn more about YIZUMI's injection molding solutions and how they can benefit your manufacturing process, visit our official website.