YIZUMI Provides Better Solution With Thixomolding Technology

How good it is to see you after two years at SNIEC in China.

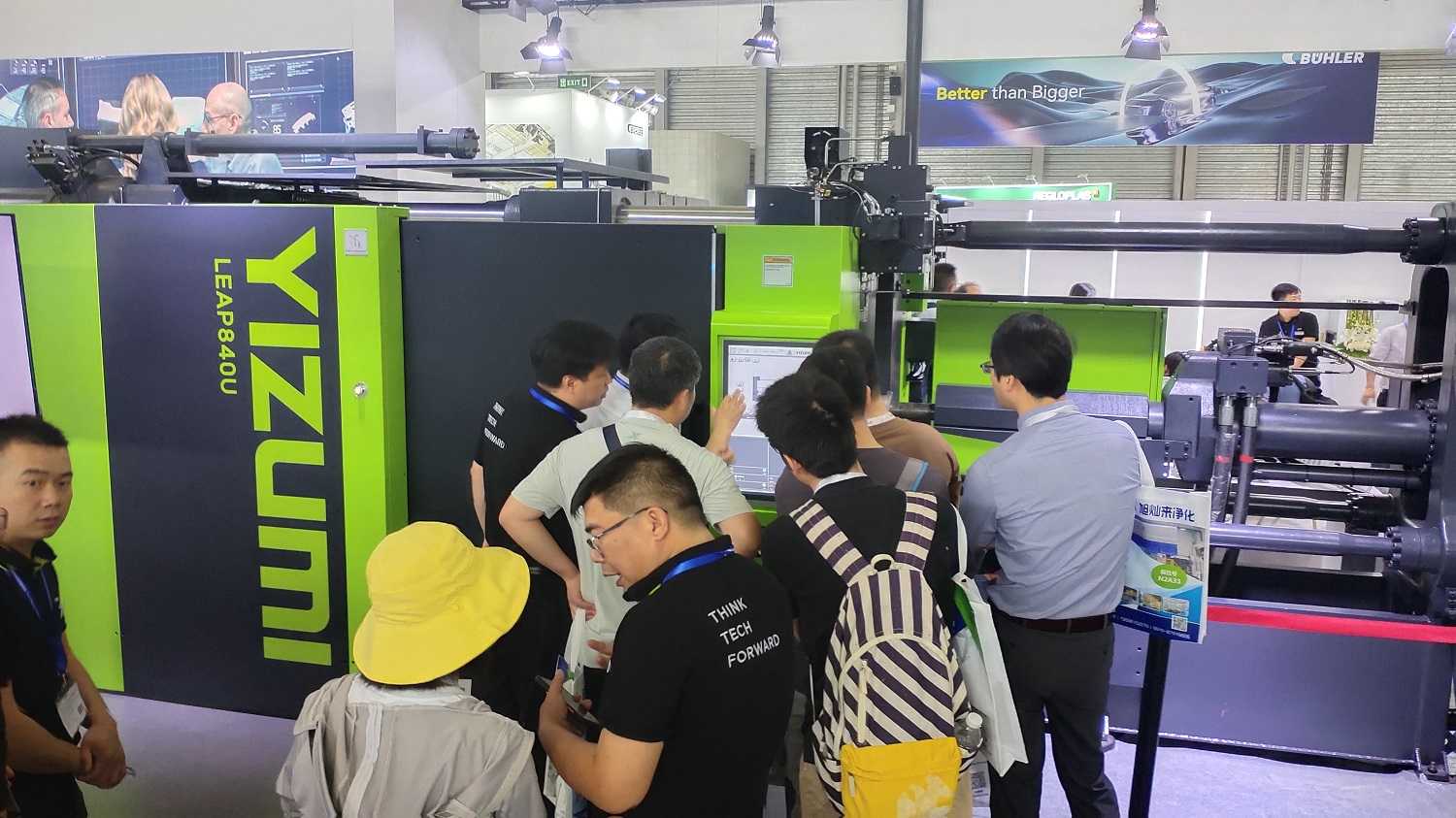

YIZUMI presents a range of solutions at CHINA DIECASTING 2023, including ultra-large intelligent die casting solution, LEAP series die casting machine, HII series cold chamber die casting machine and Thixomolding machine, attracting significant interest.

UN3200MGII

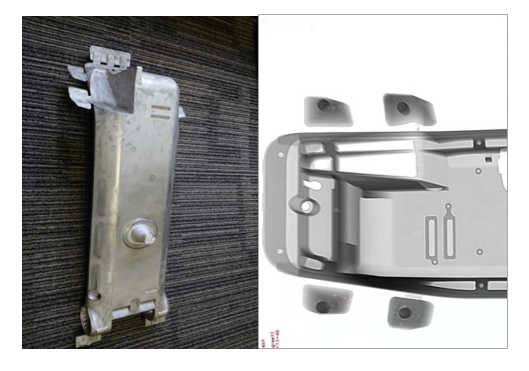

High-precision 3C components, outdoor & sports products and healthcare products have seen strong growth as the growing promotion of new energy vehicles. Green development, including energy savings and emission reduction, is prompting the popularity of lightweight magnesium alloy parts, and the Thixomolding process is gaining attention for its excellent performance and eco-friendliness.

For quite long time, the Thixomolding process was only mastered by some top manufacturers abroad. As a result of the high cost of equipment, high-quality magnesium alloy parts are niche products and pricey. In 2008, YIZUMI began the Thixomolding project with a forward-thinking vision, and since then, continuous innovation and iteration have earned recognition from global customers including Germans and Americans. Our machines are the top domestic Thixomolding equipment with up to 3 million shots, of which nearly 1 million from overseas and 2 million from domestic.

During GIFA 2023 In June, Sinyuan ZM signed a strategic cooperation agreement with YIZUMI to order a 3200T Thixomolding machine, which has the largest tonnage in the world so far. This marks another new breakthrough of YIZUMI in large-size equipment, and also marks that YIZUMI has advanced to a new level in large thixomolding machines.

Over the past fourteen years, YIZUMI has accumulated a lot of technical expertise in the development of Thixomolding equipment and technology for large thin-wall and thick-wall parts manufacturing, as well as insight into the needs of customers in the part development and manufacturing.

To better meet and serve the needs of customers, YIZUMI has made numerous improvements to the equipment in terms of easy operation, reduced downtime for maintenance and repair, reduced energy consumption, improved safety and health environment and reduced whole life costs of the equipment. Now, Thixomolding equipment developed by YIZUMI has reached top international standards.

Hot runner technology for Thixomolding

Hot runner technology, single point (skater)

Hot runner technology, multi-point

The stable and high quality production of Thixomolding products requires not only excellent equipment, but also the development of exclusive die technology, specialized process parameters, and the development and well trained operators, which are not traditionally undertaken by equipment manufacturers. As Thixomolding technology is still a niche technology, the support for those is seriously lacking. To address this issue, YIZUMI has devoted significant resources in pushing development and innovation, and our experienced team can provide full range of excellent services.

In addition, the price and lifetime of consumables are crucial in the cost control of Thixomolding products. YIZUMI has been selecting reliable consumables suppliers for years and working with customer to improve utilization, lifetime and function, among other things to meet the customers' goal of cost reduction.

"Innovation" has always been the foundation of our development, and it is also our relentless pursuit. "Customer value enhancement" is the code of our conduct. Today, a number of customers in China, Germany, and the United States have established a long-term relationship with YIZUMI after the successful production of high-quality Thixomolding parts in their respective fields. In the future, we will continue to explore new applications for Thixomolding together.

CHINA DIECASTING 2023 will continue until July 14th. To learn more exciting details, please visit the YIZUMI booth: N1A22, or follow us on https://www.yizumi.com/en/news/expo/ china_diecasting_2023.

*The Data above were acquired by testing in the factory, only for your reference. As to the specific data, please refer to the actual equipment.