Useful Downtime Maintenance Tips for Rubber Injection Machines

Dear YIZUMI RIM Customers:

Thank you for your trust and support to YIZUMI. The Chinese New Year holiday is approaching and we kindly remind you to get fully prepared for the shutdown of rubber injection molding machines before the holiday and maintain the machines to ensure good performance in the coming year.

Holiday Shutdown Precautions for Rubber Machines

1. Protection of rubber machines and molds

Before the rubber machine is shut down, the upper mold plateshould be lowered to ensure that the upper and lower mold plates are in closed status to protect the mold cavity. At the same time, it is necessary to open the mold all the way to position to ensure that the clamping piston is in the main cylinder to prevent rust on the surface of the piston, and to better protect the mold and the clamping mechanism;

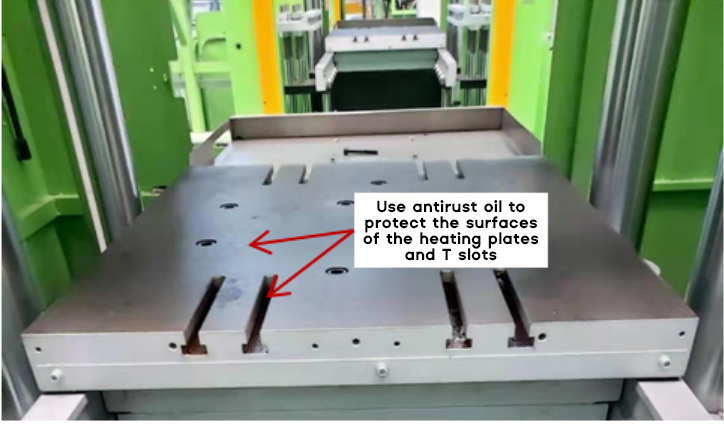

After mold opening, clean the surface of the upper and lower heating plates and the T slots with antirust oil for protection.

2. Barrel purging

Before shutting down the machine, clean up the rubber compound residue inside the plasticizing barrel and injection barrel. The plasticizing barrel is cleaned if there is no change in the injection position when rotating the screw and inject completely to clean the residue inside the injection barrel to prevent the rubber material from being cured in the injection barrel.

3. Drainage of CRB, barrel cooler and hydraulic oil cooler

First, turn off the power supply of the cooling water tower, water tower outlet pump, and thermal regulator, and then do the following protection work of drainage:

Machines with CRB

A. Shut down the machine in advance to ensure that the runner temperature drops below 35 degrees, and then turn off the oil-tempering unit motor and cooling water. It is not allowed to cut off the power supply directly, otherwise, the temperature of the CRB will be too high resulting in the rubber compound being cured in the CRB.

B. After the CRB is cooled down, close the inlet and outlet valves of the hydraulic oil cooler of the machine, and remove the inlet and outlet pipes. If the ambient temperature is lower than zero degrees, a blow gun is needed to blow out all the residual water inside the cooler (at this time, it is necessary to ensure that the solenoid valve for water is powered on) to avoid the water freezing inside the cooler resulting in damages to the cooler, or rusting or oxidation.

C. Finally, turn off the power of the air compressor equipment and release the residual air pressure.

Machines without CRB

A. Close the cooling water inlet and outlet valves of the injection/plasticizing/nozzle, and remove the inlet and outlet pipes, if the ambient temperature is below zero degrees, a blow gun is needed to blow out all the residual water inside the cooler (at this time, it is necessary to ensure that the solenoid valve for water is powered on), to avoid the water freezing inside the cooler resulting in damages to the cooler, or rusting or oxidation.

Cooling water inlet and outlet valves of machine

B. Finally, turn off the power of the air compressor equipment and release the residual air pressure.

4. Electrical protection of machines

Before the holiday, please make sure that the main power switch of each rubber machine equipment is disconnected, and the power switch of the plant’s power distribution cabinet that connects to the machine’s main power switch is disconnected, and after turning off the power supply, clean up the dust inside the electric cabinet, remove the air filter, clean it from top to bottom with a vacuum cleaner, and do waterproof and moisture-proof measures inside the electrical cabinet.

Fans for electric and power distribution cabinets

Finally, ensure the doors and windows of the workshop have been closed properly, and place rat poison at the corner of the workshop and near the entrance of equipment to prevent rats from damaging equipment wiring.

Tips: Long-term shutdown may lose the set parameters of the machine, therefore the recipes need to be stored in time.

On the occasion of the New Year,we sincerely wish you a prosperous business!