CHINAPLAS 2023 | Diversified Demonstration of YIZUMI RIM

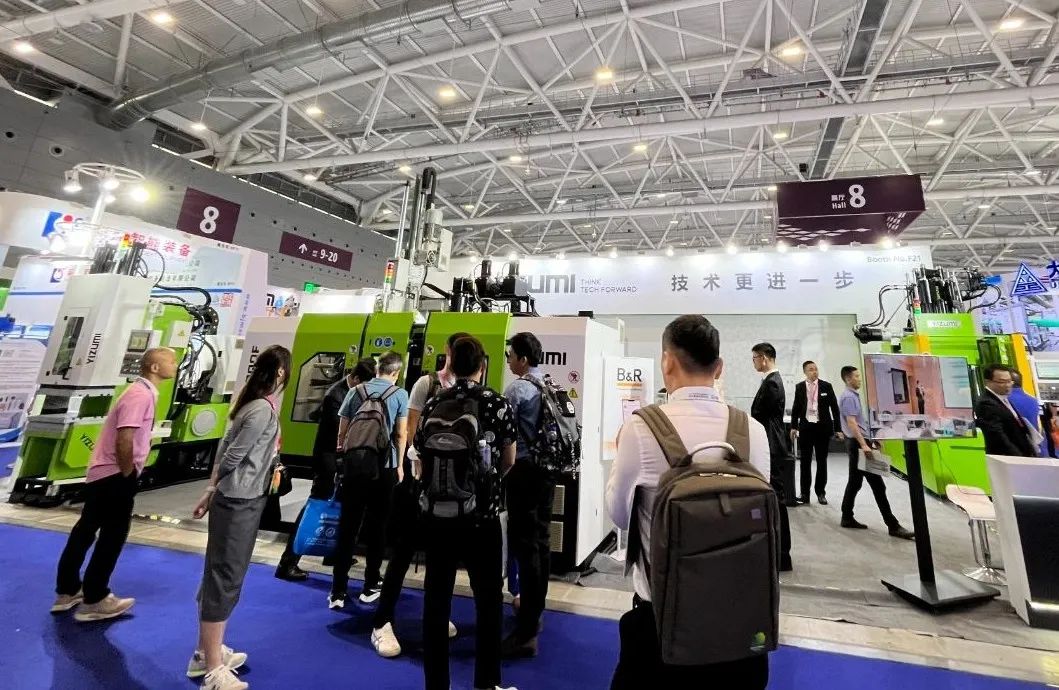

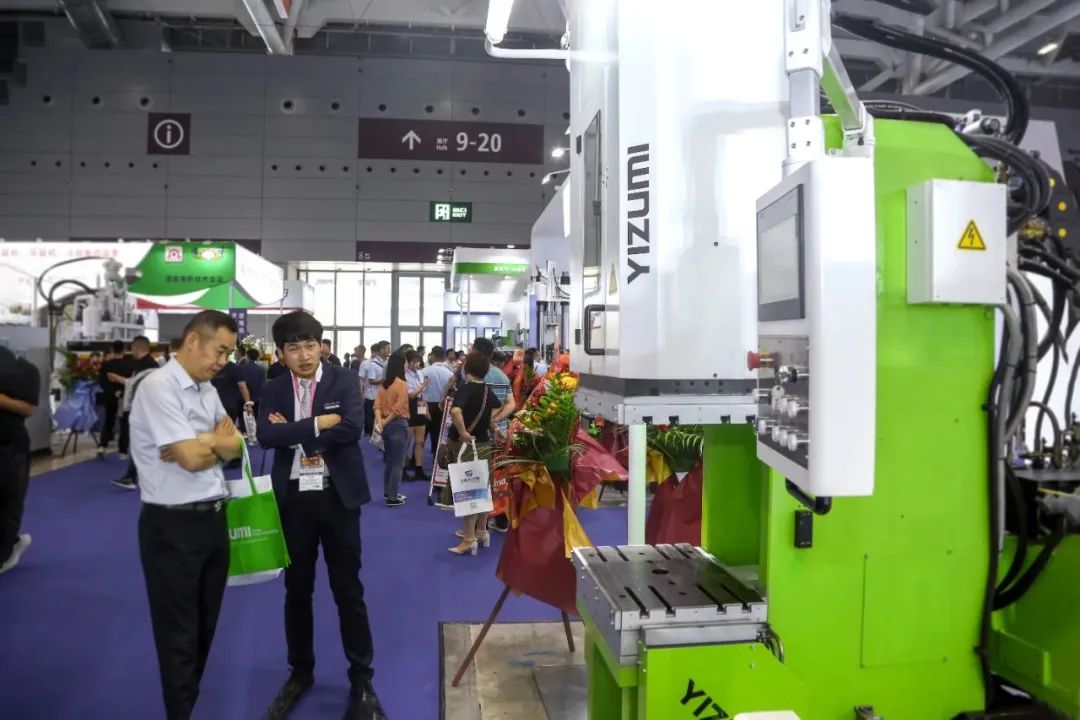

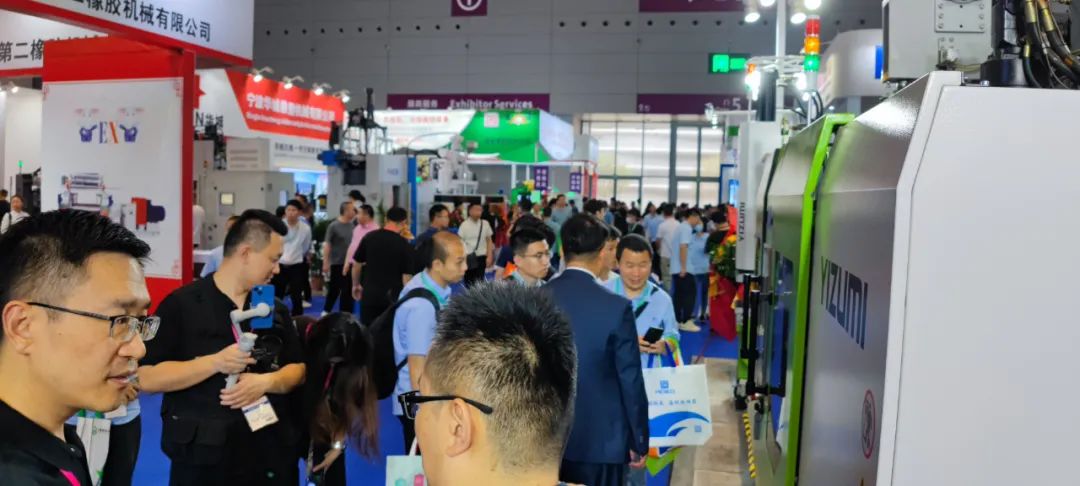

On April 19th, 2023, CHINAPLAS 2023 is ongoing at the Shenzhen World Exhibition & Convention Center, and YIZUMI Rubber Machinery presents three machine models - the horizontal injection molding machine YL-H200F, the vertical rubber injection molding machine YL-V250L and the C-frame rubber injection molding machine YL-C50L.

YL-C50L is a C-frame rubber injection molding machine with a small footprint and high structural strength features. The machine is equipped with YIZUMI 3rd generation energy and temperature management system, which takes into full consideration the convenience and accessibility of every detail in operation and maintenance. Through the modular design, there is a variety of optional injection units and demoulding devices, to meet the precision molding process of materials such as EPDM, TPE, LSR. Also, the ultra-high-pressure injection unit is available for molding special parts made of FKM and AEM, etc. With YIZUMI 4.i system, it offers a comprehensive intelligent manufacturing solution to help customers save costs and ensures long-term stable production.

YL2-V250L is a vertical rubber injection molding machine which adopts a box-type structure mold plate design, finite element stress and deformation analysis with a large safety factor to ensure better machine rigidity. The larger four-column spacing offers a bigger heating plate size and operating space, which facilitates a selection of various demoulding options.This machine model also adopts the energy-saving design in hydraulic, temperature control and process movement, responding to green manufacturing and producing environmental-friendly equipment. Adhering to the people-oriented concept, with an all-around safety door and light curtain to ensure the safety of operators while operating.

The YL-H200F is a horizontal injection molding machine that adopts the finite element analysis, its maximum mold opening speed can reach 450mm/s. A comprehensive solution with an energy-saving power system, a combination of high heat transfer with low radiation and low-load execution to realized low-energy consumption. The machine base is also an important part of this high-precision machine, which guarantees long term machine precision, even on uneven workshop floors.

At this CHINAPLAS exhibition, YIZUMI has invested abundant resources to remotely connect the exhibition site in a new way with the exhibition hall of China Wusha Factory in Shunde, enabling customers to further learn about the latest products and technologies of YIZUMI and capture the up-to-date industry information.

At the beginning of another twenty years, YIZUMI is ready to meet new challenges and sincerely welcomes industry partners to visit YIZUMI Factories for more molding solutions.

To learn more about the exciting content of CHINAPLAS, you are welcome to visit YIZUMI booth 8F21 until the 20th or continue to follow YIZUMI’s WeChat official account.