YIZUMI Presented the Latest Technologies at Fakuma

Abstract:

YIZUMI Presented the Latest Technologies at Fakuma

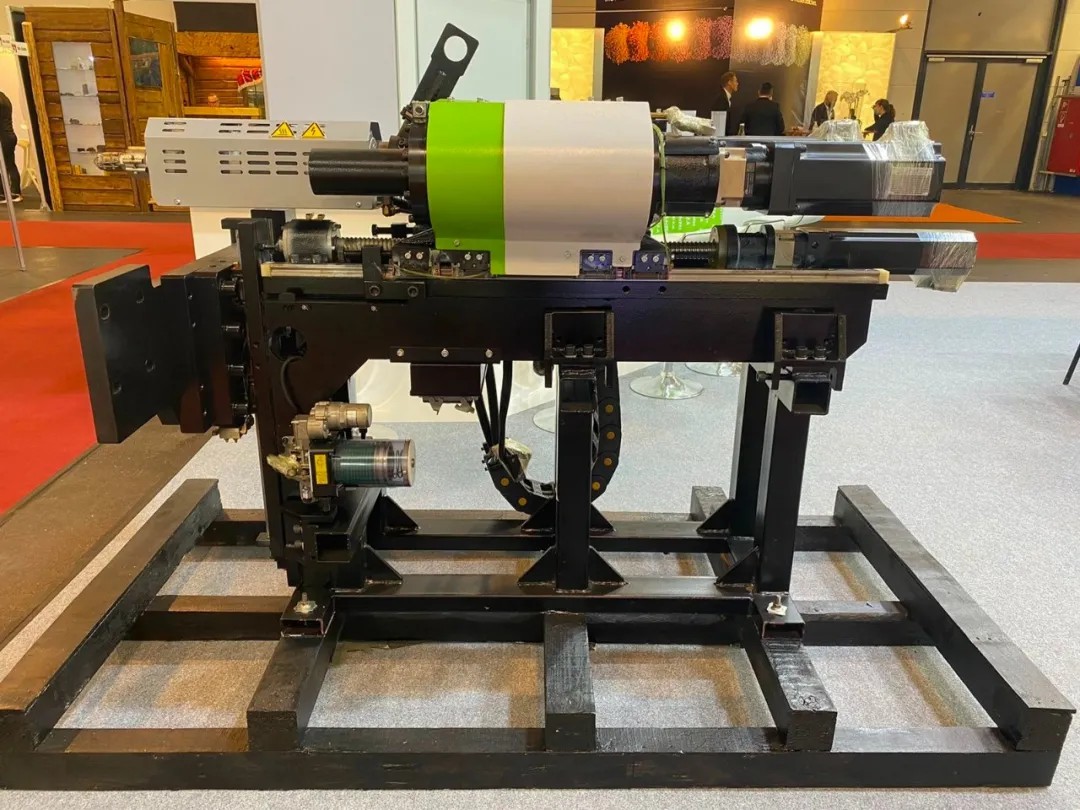

Featured Electric Injection Molding Machine Integrated Solution

At booth 5405, hall B5, YIZUMI displayed the FF series electric injection molding machine integrated solution. Since 2020, YIZUMI electric injection molding machines, including the FF series, have been introduced to the European market. Based on European and German standards, the FF series adopts a modularization design that clamping units and various injection units can be combined flexibly as per customers’ requirement. With injection speed at about 200-350 mm/s, the position accuracy of injection and mold closing & opening is within 0.02mm, its advantages of high precision, high efficiency, high stability, and automation could satisfy the requirements of European customers in different sectors. YIZIMI electric injection molding technologies and machines are widely applied in industries such as precision electronic, medical, packaging, automobile spare part, etc.

booth 5405, hall B5

Electric injection unit

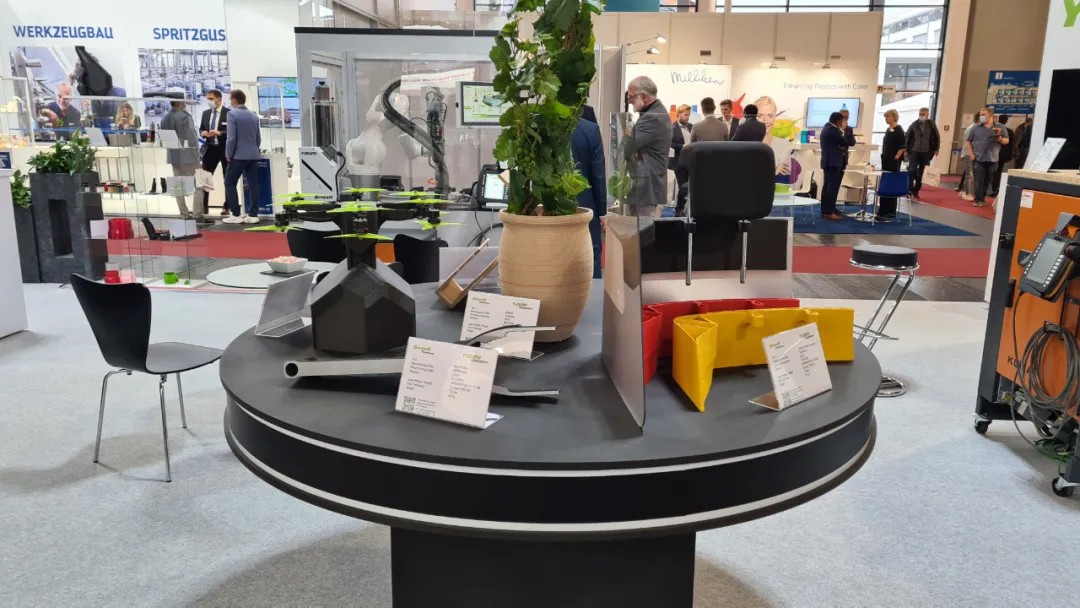

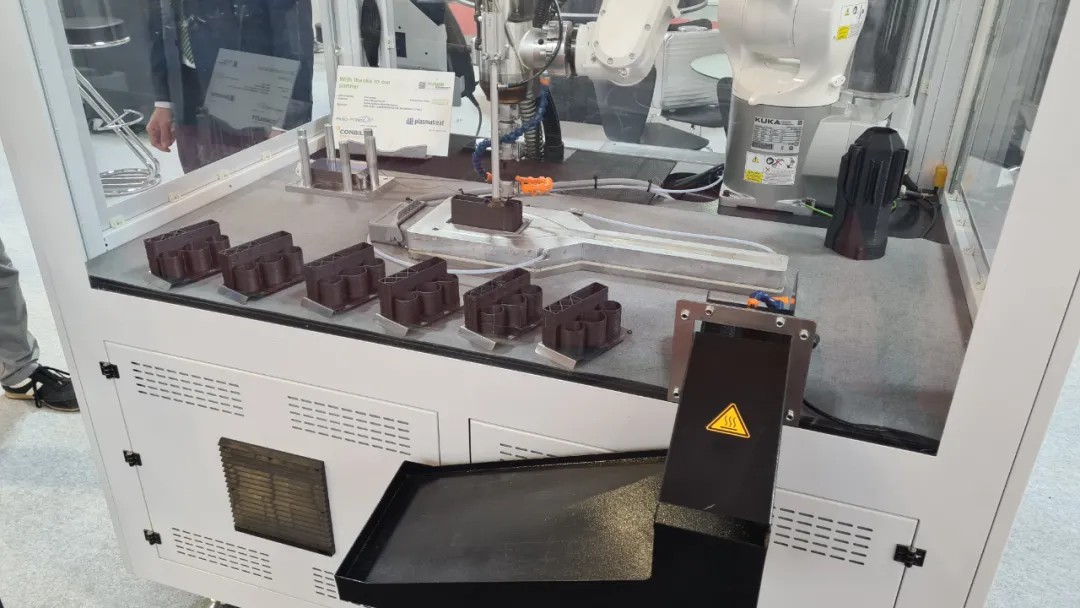

First Show of Metal-plastic Composite Molded Part

Besides, the smooth production of metal-plastic hybrid components was presented on the SpaceA-900E-500-S system. For this purpose, metal inserts were coated and then printed with a carbon fiber-reinforced polyamide(PA6+CF). The demonstrator was a pen holder, which was produced in 10-minute cycles. It is the first time YIZUMI Germany has demonstrated the successful production of metal-plastic composite molded parts on a SpaceA Industrial 3D printer. With this technology, YIZUMI Germany will possibly manufacture metal parts more cost-effectively and flexibly in the future.

Rubber injection molding machine,thixomolding machine and other integrated solutions were also exhibited on thescene. Engineers from YIZUMI Germany helpfully provided customers with detailedintroductions on engineering services in the field of additive manufacturing.