YIZUMI Dazzles at Plastex Uzbekistan 2024, Finding New Chances

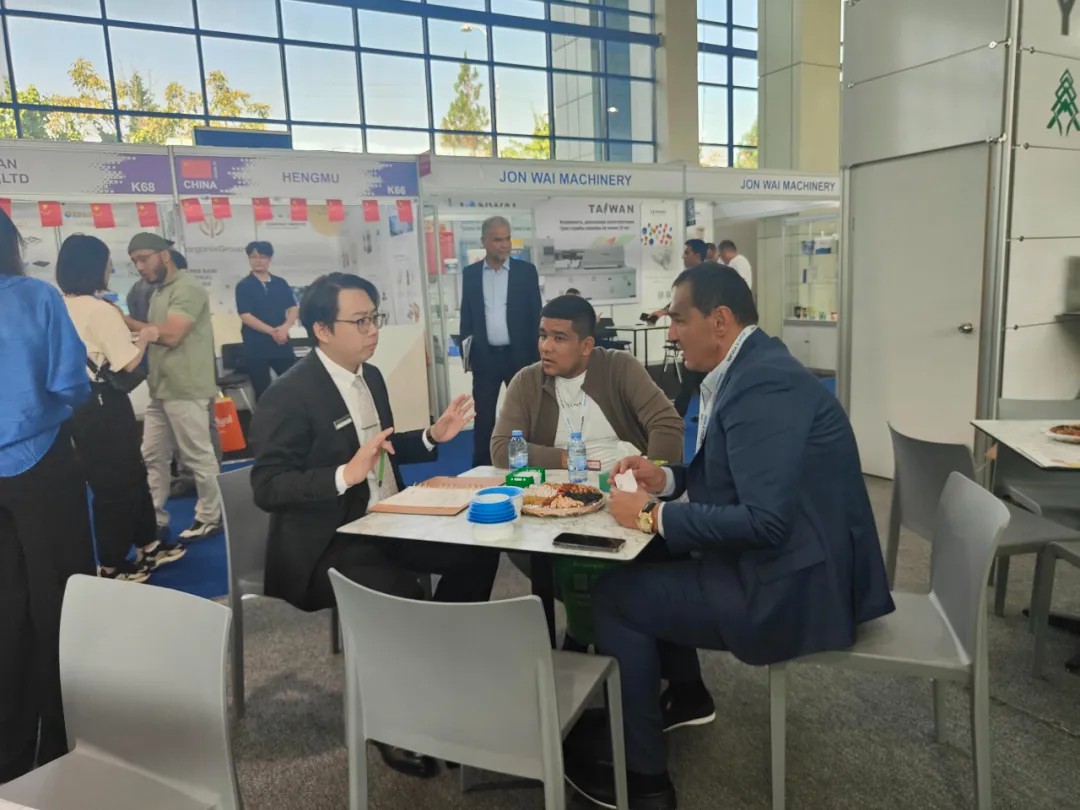

On Oct. 2, local time, the three-day Plastex Uzbekistan 2024 takes place at the Uzexpocentre NEC in Tashkent. It brings together leading companies in the global plastics and rubber industry, and YIZUMI makes a powerful return to this international stage after a year away.

At booth L100, YIZUMI and its local agent SEDIR present the P430S3 and UN260CG-P, two high-performance injection molding machines, as well as tailored-made turnkey solutions for local customer needs. The machines have received high praise from the on-site visitors for their exceptional performance, efficient production capacity, and stable operational quality.

Solutions

IML Thin-wall Barrel Molding Solution

YIZUMI is committed to becoming the most cost-effective solution provider for the packaging industry. The P-S3 series high-speed injection molding machines stand out in the market with value advantages such as efficient production, precision and stability, energy savings, wide application, and intelligent operation, making them an ideal choice for many companies seeking to enhance production efficiency, reduce costs, and achieve sustainable development.

The P-S3 series high-speed injection molding machines feature high rigidity and high injection speed, significantly boosting production efficiency. The system’s maximum pressure has increased by more than 10%, reaching up to 19 MPa, while overall clamping rigidity has improved by over 25%. This is beneficial for molding thin-walled, deep-cavity products and provides a fast and stable system solution for disposable medical consumables, food packaging, and various thin-walled plastic products.

01 Product: IML thin-wall barrel

02 Material: PP

03 Number of cavities: 4

04 Weight: 36.5g

05 Size(D*H): D120*H130

06 Cycle time: 8s

Two-color Pipe Fittings Molding Solution

The YIZUMI CG-P series high-end multi-component injection molding machine, with its outstanding technological innovation and meticulous design, not only demonstrates significant advantages in stability and customization, but also improves production efficiency, product quality, and intelligent management level, further enriching its value connotation.

Using balanced force clamping (BFC) technology, magnetically levitated turntable (MLT) technology, and digital closed-loop positioning control (DCPC) technology, along with super long sliding shoes and smart mold-opening deceleration technology, the movements of the clamping unit and rotary unit are stable and reliable. The mold-opening position repeatability is up to ±0.3mm.

Furthermore, standardized and modular design is applied to the whole machine, including the injection unit, power unit and plasticizing unit. This design, integrated with the free programming function in software makes customization more mature.

01 Product: Two-color pipe fittings

02 Material: PP, TPE

03 Number of cavities: 2+2

04 Weight: 67g

05 Size(D*H): D130*H70

06 Cycle time: 35s

As a key member of the Belt and Road Initiative, Uzbekistan's infrastructure construction is speeding up. The government's sequence of initiatives, including tax breaks, tariff reductions, and a five-year industrial modernization plan, have provided exceptionally favorable growth prospects for the chemical and plastics products industry.

The fast-moving consumer goods industry welcomes high-quality, lightweight, and feature-rich packaging materials. With the ongoing acceleration of infrastructure construction, the demand for plastic pipes and section bars has surged. At the same time, the demand for lightweight plastic parts in the automotive industry continues to rise. All of these demands drive the expansion of Uzbekistan's plastic products industry.

YIZUMI has fully grasped the huge potential in the Uzbekistan market, and its A5 and D1 series injection molding machines have become star products due to their great adaptability, stability, and efficiency. Because of their broad applicability, the A5 series models have been successfully used in various production scenarios, while the D1 series models are well-suited to the production of injection molded products in the logistics and home appliance industries, meeting the local market's urgent demand for high-quality injection molding machines.

YIZUMI's marketing strategy is based on the "agency leads distribution + headquarters offers support" concept. By working closely with its exclusive agent SEDIR, YIZUMI has achieved full coverage of sales and technical services in Uzbekistan and surrounding countries. At the same time, its headquarters constantly invests heavily in technical support and marketing to ensure a quick and accurate response to local customer requests, as well as comprehensive and high-quality service support.