YIZUMI 7K Injection Molding Machine: Breakthrough and Innovation

Driven by Industry 4.0 and smart manufacturing, the manufacturing industry is moving towards intelligence, high-end, and sustainability. As a core equipment in manufacturing, the technological innovation of injection molding machines has always been a focus of the industry.

In recent years, the demand for multi-color injection molded products in industries such as automotive and home appliances has surged, while traditional injection molding machines can hardly meet the needs of high-end manufacturing. Against this backdrop, YIZUMI UN2400D1M 7K Injection Molding Machine(hereinafter referred to as YIZUMI 7K injection molding machine)is launched. With its innovative multi-injection units, high-precision control, and intelligent operation, it has propelled the technological upgrade of China's high-end injection molding machine industry and injected new vitality into the global manufacturing.

From Follower to Leader: The Technological Leap of Domestic Injection Molding Machines

The launch of YIZUMI 7K injection molding machine marks a significant leap for domestic injection molding technology, shifting from "follower" to "leader" .This machine's key technological breakthroughs in multi-color injection molding have shattered the long-term reliance on imports for high-end precision injection molding equipment in China. It offers more advanced and cost-effective solutions to high-end manufacturing sectors such as automotive and home appliance industries.

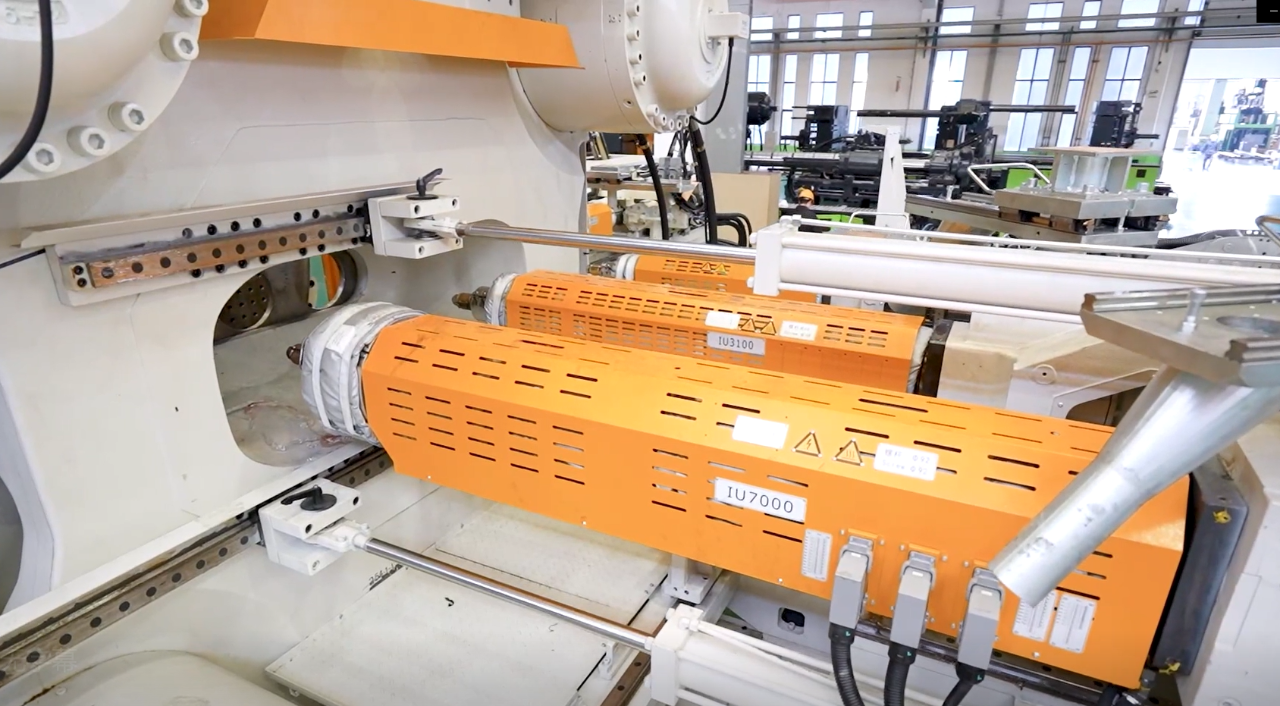

The highlights of YIZUMI 7K injection molding machine is its multi-injection units collaborative control technology and high-precision positioning capabilities, which can bring higher quality and efficiency to the production of complex process products.

The 7K injection molding machine has three parallel injection units, A, B, and C, supporting single-color molding and combinations with other injection units for up to five-color molding. Its multi-injection units collaborative control technology requires precise timing, speed, and pressure control for perfect molding. This flexible injection unit design meets diverse customer needs, improving efficiency and shortening delivery.

In addition, its rotary table is controlled by servo technology, which offers fast speed, precise positioning, and a repeatability accuracy of ±0.005°. This high-precision control technology ensures the efficiency and accuracy of multi-station rotation. Synchronized rotation of turntable pipeline and tank chain effectively reduces wear and leakage, extends the machine's service life, and lowering maintenance costs.

The unique independent temperature control system is perfectly integrated with the machine. It can operate independently and also allows for parameter settings on the KEBA control system, ensuring the precision and stability of temperature control and enhancing product quality.

Empowering High-End Manufacturing & Shaping the Future of Intelligence

High-end and intelligent manufacturing are significant trends in the future development of global manufacturing. The launch of the 7K injection molding machine demonstrates YIZUMI's precise insight into the market and its accurate grasp of industry trends.

As a high-end manufacturing tool, YIZUMI's 7K injection molding machine precisely co-injects five materials or colors in one mold. It meets the high-strength and high-precision requirements of complex parts and improves design freedomand functionality. For example, in the automotive field, it integrally forms car light components with soft rubber seals; in the electronics field, it achieves multi-component insert injection molding for thin, light electronic products with integrated functions; in the medical field, it produces medical device components with high precision and high cleanliness.

YIZUMI 7K injection molding machine, equipped with YiMES Manufactory Execution System, can achieve more intelligent production. This includes intelligent scheduling, real-time monitoring and analysis of production data, machine status supervision, and energy consumption management. YiMES, by integrating AI algorithms, can help machines autonomously optimize process parameters and precisely control every production step, ensuring the stability and consistency of product quality. Additionally, it features remote monitoring, parameter adjustment, and predictive maintenance capabilities, which significantly enhance production flexibility and response speed, further meeting the needs of high-end manufacturing for intelligent production.

In the intelligent manufacturing trend, YIZUMI has been becoming a technology innovation practitioner and industry trend leader. Its 7K injection molding machine marks a major breakthrough in injection molding technology and an important high-end manufacturing innovation. With efficient, precise, and intelligent features, it strongly supports the manufacturing industry's transformation and upgrading, driving it towards a higher-end and smarter direction.

* All data are derived from YIZUMI's factory experiments. Please refer to the customized equipment for product data.