【K 2022】IMC Molding Solution for Auto Side Door Panel

Abstract:

【K 2022】IMC Molding Solution for Auto Side Door Panel

With more attention to the importance of environmental preservation and energy conservation, there i...

With more attention to the importance of environmental preservation and energy conservation, there is a higher requirement for the precision, energy conservation, environmental protection, efficiency, quietness, and stability of injection molding machines.

To better satisfy market expectations on environmental protection and energy conservation,YIZUMI introduced a type of hybrid injection molding machine that combines a two-platen hydraulic technique with pure electric technology.

Value Advantages

Based on the D1 series two-platen hydraulic technique and the FF series pure electric technique, the YIZUMI D1-E series hybrid injection molding machine – UN500D1-E integrates different mechanical units efficiently through modularization while retaining their own advantages. With more stable product quality, lower energy consumption, and higher efficiency, the UN500 D1-E could not only has the features of all-electric machine in terms of stability and precision, but also helps to reduce the investment cost to a large degree.

Same to the D1 series, the UN500D1-E can expand the injection-compression molding and injection-breathing molding processes, to reduce clamping force and offer a higher level of uniform holding pressure, improved product surface quality, increased product density, and better solutions to overcome product warping problems. That means that UN500D1-E could find widespread application in situations requiring high clamping force, injection precision, efficiency, and lower energy consumption, such as those involving automotive, aviation, home appliances, consumer electronics, medical electronics, and smart wearable plastic products.

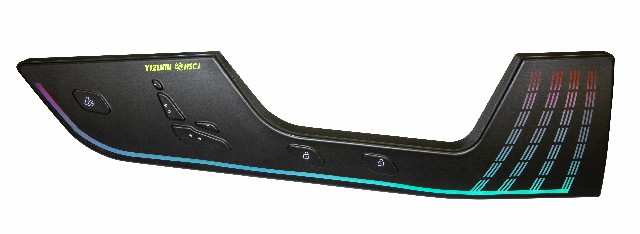

At K 2022, YIZUMI teamed up with Shenzhen Hesheng Chuangjie Technology Co. Ltd. to develop 3D automotive side door trim panels using IMC in-mold circuit technology. The process of IMC Molding Solution for Auto Side Door Panel is to print decorative patterns and conductive circuits on film substrates successively. Then, integrate the patterns and touch circuits into a 3D smart touch panel through injection molding process. It offers various advantages including light weight, free design, excellent performance, and simplified process.

Product: IMC Panel for Auto Side Door Machine: D1-E Series Hybrid Injection Molding Machine Cavity: 1 Material: ABS920 Size(L×W×H): 456*125.1*20mm Weight: 80g/pc Cycle time: 90s Partner: HESHENG CHUANGJIE (Mold)