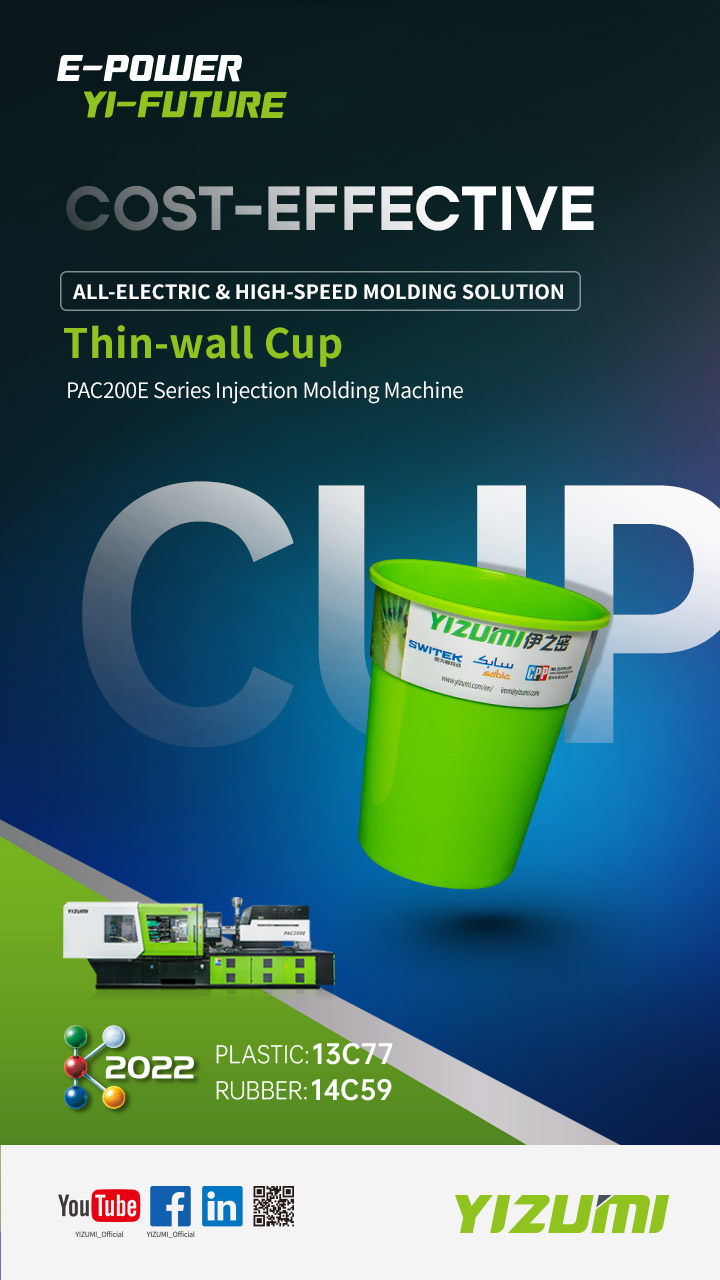

All-electric & High-speed Molding Solution for Thin-wall Cup

Abstract:

The PAC-E specifically designed for the thin-wall packaging market, which has higher requirement in product size coverage, product shape and cleanliness. The machine performance is improved pointedly to better meet the production demand of thin-wall products.

With the market competition becoming ever ferocious, there is an increasing requirement of product packaging. Also there are higher performance requirements of all-electric injection molding machines in context of “efficiency improvement, cost reduction, environmental protection and energy saving”.

Therefore, YIZUMI launched a more cost-effective machine, namely PAC-E all-electric high-speed (referred to as PAC-E) injection molding machine, to offer customers better options for product upgrade.

The PAC-E specifically designed for the thin-wall packaging market, which has higher requirement in product size coverage, product shape and cleanliness. The machine performance is improved pointedly to better meet the production demand of thin-wall products.

The Advantages of PAC-E All-electric High-speed Injection Molding Machine

The new PAC-E injection molding machine has been comprehensively improved in terms of cleanliness, precision, and energy saving while retaining the advantages of the original PAC series in the precision and efficient production of thin-wall packaging containers, providing customers with a customized one-stop solution, including machines, molds, auxiliary devices, and after-sales support to meet the diversified production needs of our customers in the future.

In the field of thin-wall packaging, cycle time reduced by one second could increase production capacity of 10%, or even more than 20%. The innovation and upgrade of technology can better ensure the smooth operation of the PAC-E injection molding machine during high-speed production.

Additionally, compared to the hydraulic high-speed machine, PAC-E creates no hydraulic oil leakage or contamination of the products - ideal for production applications in medical supplies and food packaging industries.

Additionally, compared to the hydraulic high-speed machine, PAC-E creates no hydraulic oil leakage or contamination of the products - ideal for production applications in medical supplies and food packaging industries.

At K 2022, the all-electric and high-speed IML molding solution for thin-wall cup integrates PAC-E series injection molding machines, special mold for thin-wall molding and IML system to achieve the production of thin-wall cups. This turnkey solution with high efficiency, cleanliness and stability can satisfy diversified production demands for customers.

Product: IML Thin-wall Cup

Machine: PAC-E All-electric High-speed Injection Molding Machine

Number of cavities: 4

Material: PP

Weight: 6.6g/piece

Cycle Time: 4±0.5s

Partner: SWITEK

* The Data above were acquired by testing in the factory, only for your reference. As to the specific data, please refer to the actual equipment.