YIZUMI Thixomolding Technologies Wins High Praise in Shanghai

Abstract:

July 4-7, 2024

NECC, Shanghai

Booth No.: 2F21

On July 4th, the 22nd China International Foundry Expo (Metal China), the 17th China International Die Casting Industry Exhibition, and the 17th International Nonferrous and Special Casting Exhibition, hosted by the China Foundry Association, take place at the National Exhibition and Convention Center (NECC) in Shanghai, China. They provide the foundry industry with an unprecedented technological exchange event.

UN300MGII leads the trend

in Thixomolding technology

YIZUMI makes a stunning presence with advanced Thixomolding technologies at booth 2F21, capturing the warm attention of many visitors. The UN300MGII is a small injection volume model that integrates sophisticated Sino-German technologies. It introduces cutting-edge European hot runner technology, which significantly improves filling performance and optimizes overall product quality.

In terms of design, UN300MGII incorporates three sizes (large, medium, and small diameter) of the barrel assembly to meet customer needs for various applications, ensuring maximum molding quality and yield. In terms of power system, it uses an advanced servo energy-saving system to effectively reduce energy consumption while also benefiting the environment.

In addition, we have deeply refined its motion control, which not only enhances overall operational efficiency but also provides customers with higher output and molding quality. All of these improvements provide YIZUMI with more competitive advantages and create more value for our customers.

Thixomolding technology propels

the lightweight of NEVs

New energy vehicles are becoming increasingly popular as energy saving, emission reduction, and green development concepts gain traction. At the same time, the market's demand for lightweight upgrades to high-precision 3C electronics, outdoor sports equipment, and healthcare products continues to rise, showing strong growth. In this context, the Thixomolding technology has gradually gained popularity due to its superior performance, high safety, and environmental properties.

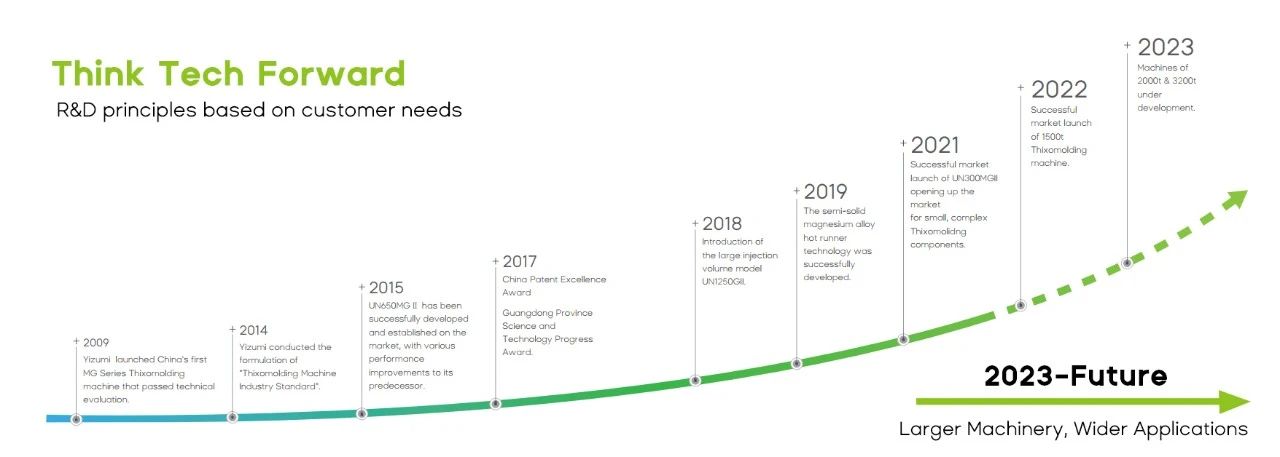

For a long time, the Thixomolding process has been mastered by costly imported equipment, resulting in a high price and a small market for high-quality magnesium alloy parts. In 2008, YIZUMI launched a forward-thinking Thixomolding project with the goal of lowering prices, broadening the market, and propelling the application and development of magnesium alloy parts.

YIZUMI has spent 16 years developing Thixomolding equipment to compete with world-class brands. In addition, YIZUMI is building a technical system for the development of Thixomolding products, which will serve as the standard for the development of complex and ultra-large parts, largely lowering the risks of mold opening.

And since then, YIZUMI Thixomolding machines have earned wide recognition from global customers for their continuous innovation and iteration. So far, our machines have received up to 4 million shots, with nearly 1 million from overseas and 3 million from domestic, making YIZUMI an industry leader in Thixomolding equipment.

In response to the rapidly expanding market for NEV parts, YIZUMI launched the UN3200MGII model, one of the world's leading model in three key performance parameters: injection capacity, melting supply capacity, and locking force, embodying our principle of "Sustainable, innovative technology for humankind".

Recently, a UN3200MGII machine has been successfully delivered to Sinyuan ZM for producing high-precision automotive parts, which is expected to boost the mass application of ultra-large magnesium alloys in automotive lightweighting.

Being a good industry leader

drives the technological development of Thixomolding

The China Foundry Association convened the Thixomolding Working Committee for 2024 for its first meeting in March. At this meeting, Dr. Zhou Jun, YIZUMI's Deputy General Manager and CTO, and General Manager of YIZUMI Die Casting Machine Division, was appointed the rotating director for the year. At the same time, the meeting identified Thixomolding as a key priority for 2024.

In this regard, Dr. Zhou Jun stated that as a global company that cultivates molding equipment in multiple industries, YIZUMI is confident in our ability to become an industry leader. We are committed to developing and promoting Thixomolding technology. We also actively pursue research into semi-solid molding technology of aluminum alloys, and have made significant advances in various vital industries, including autos and communications.

In the future, YIZUMI will further integrate resources, strengthen the technological development, and actively seek cooperation with more like-minded partners to promote the expansion of Thixomolding technology to a wider range of application scenarios and markets, thereby contributing to the industry's continuous growth and innovation.

*The data above were acquired by testing in the factory, only for your reference. As to the specific data, please refer to the actual equipment.