YIZUMI Supports NEV Lightweight Development with Four Solutions

Abstract:

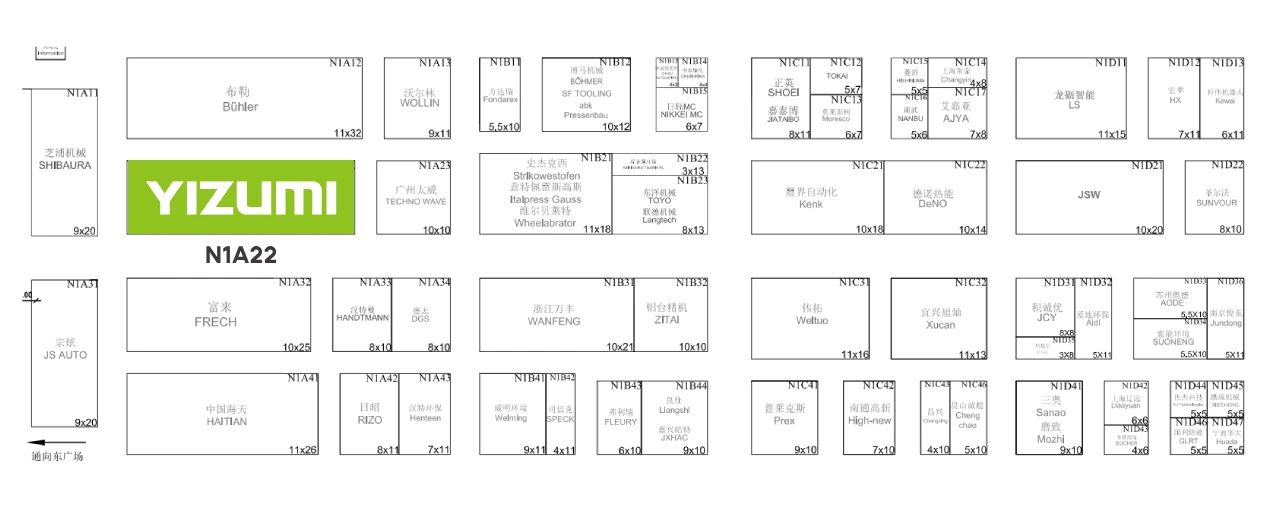

July 10-12, 2024

Shanghai New International Expo Center, China

Booth A22 in Hall N1

On July 11th, the CHINA DIECASTING and CHINA NONFERROUS 2024 continue at the SNIEC in China. YIZUMI presents several innovative technologies and products on-site, providing all visitors with an unforgettable experience.

Four major themes of YIZUMI

LEAP series die casting machine

benchmarks against world-class die casting machines

The LEAP series die casting machine, developed by YIZUMI's Sino-European R&D team with years of die casting experience, has drawn wide market interest for its outstanding features. It has undergone comprehensive upgrades and optimizations in the injection system, control system, and other areas. The self-developed Yi-Cast injection system, in particular, offers world-class speed and intensification performance and can monitor the die casting process in real time.

In addition, it adopts the ORCA intelligent control system, which can monitor up to 100 die casting parameters to ensure stable product quality. Its servo+feeding technology meets the strict requirements of die casting processes such as aluminum and magnesium alloys, and the production of complex automotive parts. It is worth mentioning that the LEAP series has launched ultra-large models to meet the demand for large integrated die casting parts, promoting the development of lightweight and integrated automobiles.

Thixomolding machine

makes the forming of magnesium alloys as easy as plastic injection molding

Since 2008, YIZUMI has consistently focused on the market orientation of magnesium alloy products and successfully predicted the trend of lightweight demand. Its engineers have conducted extensive research into production requirements, and now, its Thixomolding equipment has advanced three key parameters, including injection capacity, melting supply capacity, and locking force, to a global leading level.

It can be configured with different barrel assembly specifications to meet customer needs for various applications, ensuring maximum molding quality and yield. All of these innovations and improvements surely offered YIZUMI competitive advantages and increased customer value.

HⅡ series cold chamber die casting machine

provides a higher competitive OEE

Based on years of operating experience with the H series die casting machine at customer sites and in-depth research and analysis of the die casting process, YIZUMI launches the 2nd generation of the H series cold chamber die casting machine HⅡ, the result of a collaborative effort between YIZUMI's Chinese R&D team and its European die casting experts.

The HⅡ series model has improved the injection performance, providing customers with higher injection control accuracy and repeatability. The redesigned die closing unit improves overall machine stability, shortens cycle time, enhances platen rigidity, and extends lifetime, assisting customers in achieving higher Overall Equipment Effectiveness (OEE).

And now the HⅡ series model has gained extensive market recognition for its high precision, efficiency, excellent safety, and user-friendly design, bringing new impetus to the die casting industry.

Yi+ Intelligent Manufacturing Platform

empowers intelligent die casting

Focusing on the molding and die casting industry, the Yi+Platform takes advantage of the Industrial Internet, Cloud, and Big Data to solve enterprise management pain points in production, quality, equipment, and molds via comprehensive digital tools such as equipment condition monitoring, efficiency statistics, equipment maintenance, troubleshooting, process parameter monitoring and traceability, and production process control, etc. Auxiliary machinery in the die casting cell allows real-time monitoring and sharing of production parameters through interconnection and timely error correction to ensure production stability for improved product quality. Customers can also connect to YIZUMI's intelligent manufacturing unit through 5G+AR digital twin, providing a new experience in intelligent die casting.

This big event will continue to July 12th, for more enthusiastic content about YIZUMI at CHINA DIECASTING and CHINA NONFERROUS, please visit our booth at A22 in Hall N1 or follow us on social media.

YIZUMI Booth

*The data above were acquired by testing in the factory, only for your reference. As to the specific data, please refer to the actual equipment.