The Industry-Leading YIZUMI CONNECT 2023 is Ongoing!

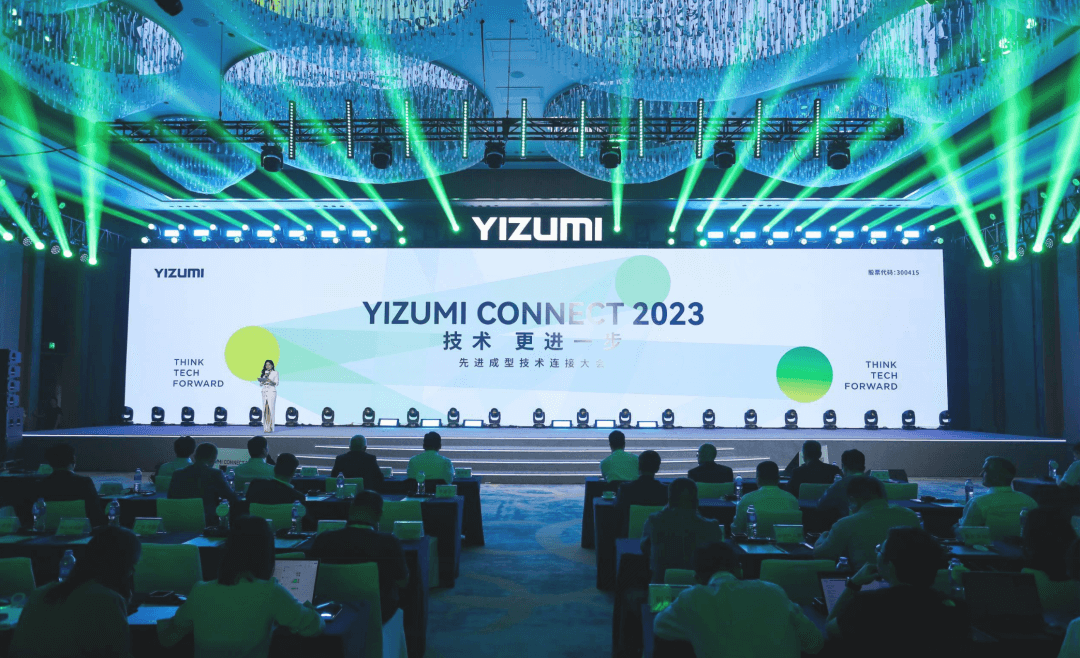

On April 18th, YIZUMI CONNECT 2023 (Die Casting Section) is successfully held in Foshan, China. More than 400 domestic and foreign vehicle manufacturers, well-known die casting factories, and customers have attended this grand event to witness YIZUMI's commitment towards "Think Tech Forward".

01 Distinct solutions for die casting and metal molding

meeting the "diversified" needs of global markets

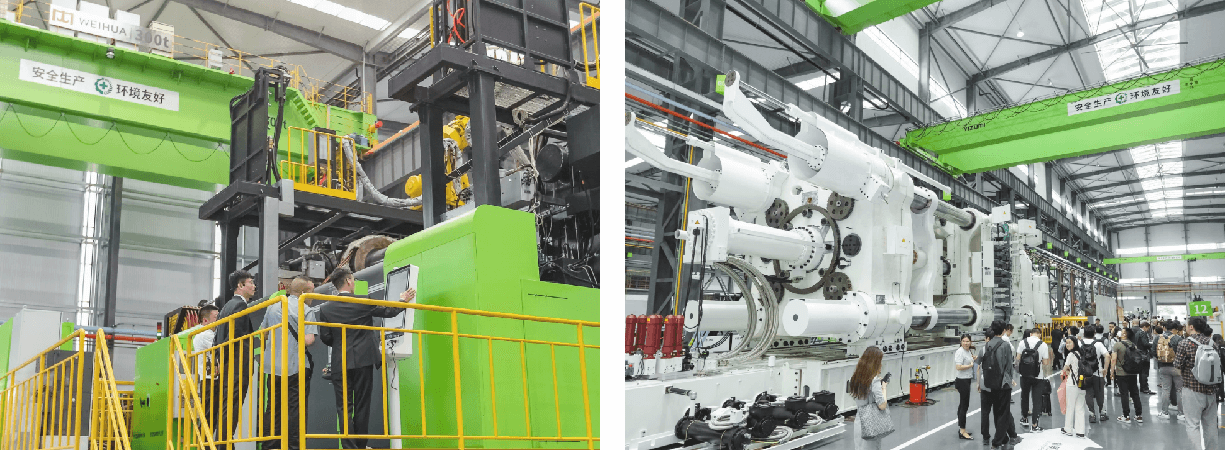

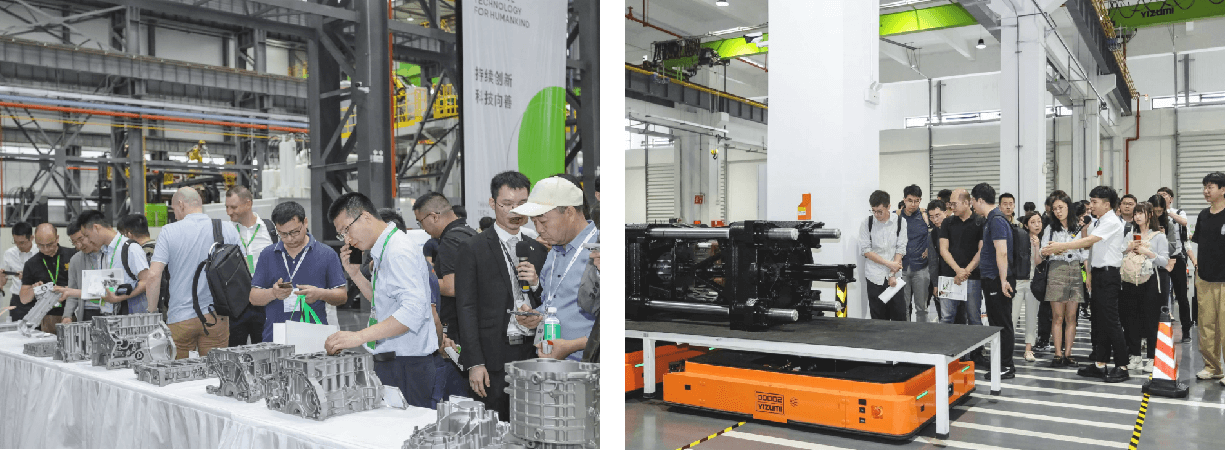

In the morning, the guests have been taken on a tour of YIZUMI's facilities, including the Die Casting Machine Factory at China Gaoli Headquarter, the YIZUMI i-Factory, and the Ultra Large Die Casting Machine Factory, to explore the road connecting advanced casting and digitalization.

At YIZUMI i-Factory, the guests have witnessed the future direction of equipment manufacturing technology. The i-Factory, built with the concept of "carbon neutrality," achieves full digitalization across all aspects of production management. This allows for accurate handling of production planning, product quality, and equipment operation status, giving the company a brand-new production experience and efficiency.

At YIZUMI Ultra Large Die Casting Machine Factory, the visitors have viewed the development and transformation to the "era of ultra-large die casting". In order to better meet the needs for the production and assembly of ultra-large die casting machines, we have invested in an advanced layout in the factory`s height and span. The factory is equipped with a 300T crane, allowing for the assembly of ultra-large die casting machines with locking forces of up to 20,000 tons, promoting YIZUMI to become a leader in the field of "ultra-large integrated die casting".

Later, the guests also have had a close look at the 9000T and the 7000T die casting cells of YIZUMI's new LEAP series ultra-large die casting machine. Further exhibits included a 1500T thixomolding machine, a HII-S series cold chamber die casting machine as well as a 3D printed spray head and AR glass applications among other innovative products. The guests have gained a deeper awareness of YIZUMI's capabilities and technological innovation in the field of die casting & thixomolding with its turnkey solutions underlined with an appreciation of our robust manufacturing capabilities.

With a good understanding of the cutting-edge technology of die casting industry, the guests have been thoroughly impressed by the scale, strength and industry influence of YIZUMI, and acknowledged that YIZUMI's i-Factory and Ultra Large Die Casting Machine Factory represent a significant milestone in the company's development. Moreover, their official inauguration is a critical step towards our vision of "To be a world-class molding equipment solution provider".

02 Keep building an open, cooperative, and shared

exchange platform of "integrated die casting solutions"

In the afternoon, the "YIZUMI Integrated Die Casting Forum" has been held at the Hilton Hotel in Foshan. The forum has focused on the industrial hot topic of "integrated, structural die casting", and the participants have had a comprehensive and in-depth sharing of the technologies in raw materials, tooling technologies, structural parts and process developments.

At the forum, YIZUMI has released its new development strategies, brand image, and cutting-edge technologies. Mr. Richard Yan, Chairman and CEO of YIZUMI, said, "YIZUMI will adhere to the transformation path of high-quality development driven by technical innovation based on the globalization strategy. Taking the realization of customer value and life-changing technologies as the focus and orientation, with a gradual shift from mainly following innovation to independent innovation, YIZUMI will take the lead in China's molding equipment manufacturing industry and ceaselessly break our own boundaries to achieve breakthroughs in products and technologies, in services and values, and in operation and efficiency. In the future, YIZUMI is committed to becoming a world-class molding equipment solution provider."

To achieve its strategic goals, YIZUMI will develop and master core technologies and implement a technology-leading strategy. In this regard, Dr. Zhou Jun, CTO of YIZUMI, said in his speech, "YIZUMI's technology strategy is to build an industry-leading technical innovation ecosystem on the basis of the Global Innovation Center. We focus on the integrated solution of polymer materials and light alloy materials molding to facilitate our partners; We focus on innovative molding processes to add value to our partners' needs; We focus on low-carbon and sustainable practices to minimize the environmental impact of our partners' production process; And we focus on Industry 4.0 to make the production of our partners more efficient."

At the forum, Mr. Tong Guodong, Senior Officer of Materials and Lightweight Research Institute of China FAW Group Co., Ltd., has delivered a keynote speech on the Application and Key Technologies of Integrated Die Casting Parts for Automobile Body. He elaborated in detail on the application trends of lightweight materials including die casting aluminum alloys. Further the presentation included developments at FAW of structural body parts in die casting with aluminum alloys. He also confirmed that lightweight solutions in automobiles and especially the integrated die casting of structural parts have become the development trend of the industry.

Mr. Lin Zhaofu, Senior Manager of the Casting Process Design Institute of Manufacturing Center of Chongqing Changan Automobile Co., Ltd., has delivered a keynote speech on the Development and Demand of Casting Process under the New Energy Transformation of CHANGAN AUTO. He introduced the development of auto manufacturing, followed by the demand for integrated casting. The speech also covered research and analysis on cost, safety, product design, materials, CAE, casting process, tooling as well as equipment in the production line and logistics. In addition, he shared insights on technical difficulties which might occur in the development of integrated die casting processes, and which skills are needed to master and ensure a successful casting process of these complex components.

Stefan Fritsche, CSO of YIZUMI Die Casting and Metal Forming, has delivered a keynote speech on the LEAP-World Class Casting Technology for Ultra-Large Structural Casting parts. He pointed out that the LEAP series die casting machines are key products of YIZUMI to move towards a world-class enterprise. The independently developed Yi-cast injection system features highest injection capacity, precision and repeatability which proves vital for a successful injection process of ultra-large integrated die casting structural parts characterized by long filling distances and thin walls. The strong power and precise real-time-closed-loop control of this system ensures highest casting quality performance from shot to shot. Moreover, to realize an efficient and low-cost production of integrated die castings, it is important to begin with a well-executed casting part design followed by a carefully crafted tool design based on correctly interpreted process and thermal-balance simulations. And finally a highly capable die casting machine, such as LEAP, embedded well in an integrated automation cell will ensure a high production output.

A strongly increasing market share of new energy vehicles drives the demand for lightweight materials as integrated structural die castings technology has attracted great market attention. In the era of new energy vehicles, die casting manufacturers meet many opportunities, but also face huge challenges. For the overall sound development of the integrated die casting industry, it is necessary to promote the innovative cooperation among upstream and downstream manufacturers of the industrial chain. At the end of the forum, representatives from 12 enterprises and universities such as FAW, Changan and Baosteel have witnessed thelaunching ceremony of "Integrated Die Casting" Industrial Chain Collaborative Innovation Alliance.

The Alliance aims to extensively unite the integrated die casting industry to pool resources and strengthen the cooperation among all parties for coordinated development of the industrial chain. This will include exploring both domestic and international markets for integrated die casting approaches in order to comprehensively improve the technical capability and competitiveness in the industry. The alliance will also promote the application and overall development of this industry; promote all parties to strengthen the cooperation in technological innovation, industry exchange and application promotion. Further activities include to foster innovative talents for this industry to stimulate the innovative vitality in this field and jointly raise this industry’s level and innovation capability.

YIZUMI has always been committed to connecting global wisdom, creating a global innovation platform and establishing a strategic alliance for industrial technologies to promote technological progress and meet customer needs with wisdom and innovation. As a result, YIZUMI has achieved diversified product coverage and global operation, and is capable of providing more advanced and higher-ROI molding equipment system solutions for global customers.

In the future, YIZUMI will take full advantage of the role as an industrial leader to promote and form a development landscape within a knowhow cluster to progress and take part in promoting intelligent manufacturing. In addition, with sustainable strategic development goals, we will transform the technological process to gradually realize low-carbon and green manufacturing solutions. Working with upstream and downstream partners will allow us to implement environmentally sustainable industrial solutions.