LEAP Series Die Casting Machines Are Ideal for Complex Parts

On June 13th, the 15th International Foundry Trade Fair with Technical Forum (GIFA 2023) enters into its second exhibition day, please follow us to have a close look around. Today, we introduce to you in detail the core performance and highlights of the new LEAP series die-casting machine, and explain how it may help customers and YIZUMI to leap ahead.

As the birthplace of cars, Germany has the longest history of producing cars. Aluminum, with its great weight to strength ratio and its easy recyclability, is an important material for automotive manufacturing. It is therefore widely used in automotive applications such as body in white structures, electro motor - and battery housings as well as for interior components and for conventional powertrain castings. In its diverse applications, aluminum strongly contributes to attractive lightweight solutions supporting the automotive industry in its quest to lower emissions.

As a company deeply involved in the field of metal forming, YIZUMI understands the needs and requirements of the industry. Based on local market demands and industry developments, YIZUMI is proud to present its attractive and well received LEAP series 840U model at GIFA.

The LEAP series is a brand-new model launched by YIZUMI in July 2021. The LEAP technology provides our customers with highest casting precision and top of the line reproducibility. With its innovative hydraulic and high performing control system with intuitive HMI, ensures maximum casting process control to achieve highest production efficiency. LEAP is the high-end die cast solution of YIZUMI providing state-of-the-art casting performance for our customers.

The entire series of LEAP models are equipped with the self-developed Yi-Cast injection system. This high performing real-time-closed-loop injection control with self-learning features ensures highest precision and top of the line casting process repeatability. The modern ORCA control system, with its intuitive user surface makes complex process control easy. An innovative two-stage hydraulic drive group ensures highest machine performance with lowest energy consumption. Jointly developed by the YIZUMI Sino-European technical team, the LEAP die casting machine fully meets any process requirements of complex aluminum & magnesium components.

Nowadays, driven by the demand for lightweight design, key components of new energy vehicle bodies are fast developing towards large and thin-walled structural castings. The die casting process is ideally suited to integrate functions in order to reduce down-stream joining processes.

Adhering to the success of the LEAP series die-casting machines, in 2022, YIZUMI successively launched the LEAP 6000-9000T ultra large series die-casting machines to meet the demand for large-scale integrated die-casting parts, promoting the application and popularization of integrated die-casting components.

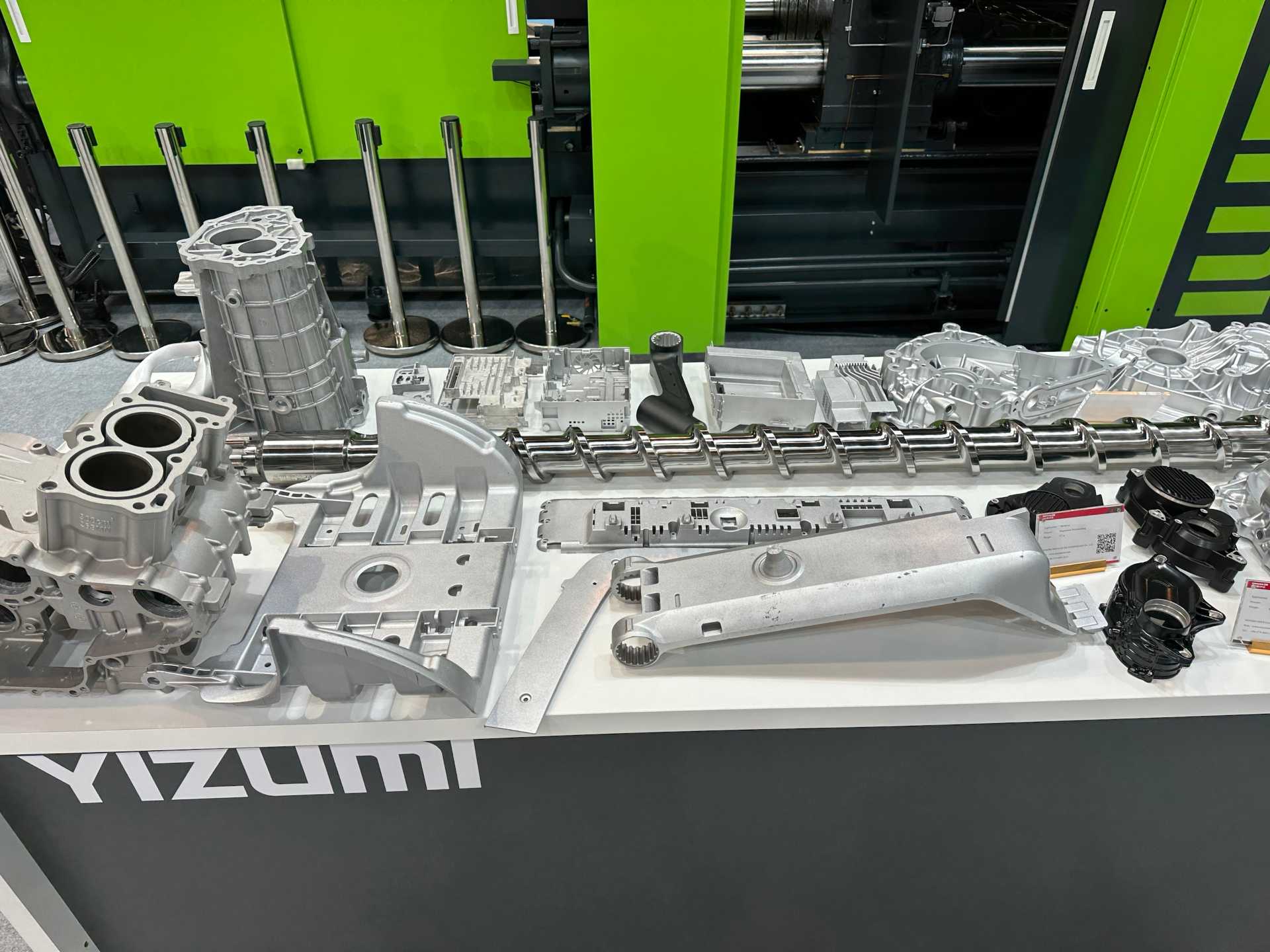

On the YIZUMI booth, various styles of die cast products are displayed. Among them, the "super large product" jointly completed by YIZUMI and a domestic Chinese vehicle manufacturing enterprise has received widespread attention. The external dimensions of this product are 1875x1617x736 mm, which currently is one of the largest known integrated structural die-casting component. The shot weight exceeds 100 kilograms, and the average wall thickness is only 3 millimeters, making it a huge challenge for the die-casting process. Thanks to the high dynamic injection performance of the LEAP series die-casting machine, the molding process with a maximum filling distance of over two meters could be managed well. The LEAP9000T ultra large die-casting machine with a locking force of over 100,000kN is ideally suited to cast such large components. In the future, as lightweighting and electrification continue to drive the development of automotive design, growth for integrated structural components will continue. Having successfully implemented various ultra-large die casting machine solutions, YIZUMI is proud to offer its highly productive ultra-large manufacturing cells to the wider market.

GIFA 2023 will continue until June 16th. To learn more exciting details, please visit the YIZUMI booth: 11A42, or follow us on https://www.yizumi.com/en/news/expo/t20536.

*The Data above were acquired by testing in the factory, for reference only.