Applications of Semi-solid Process at YIZUMI

Abstract:

Applications of Semi-solid Process at YIZUMI

I. Introduction

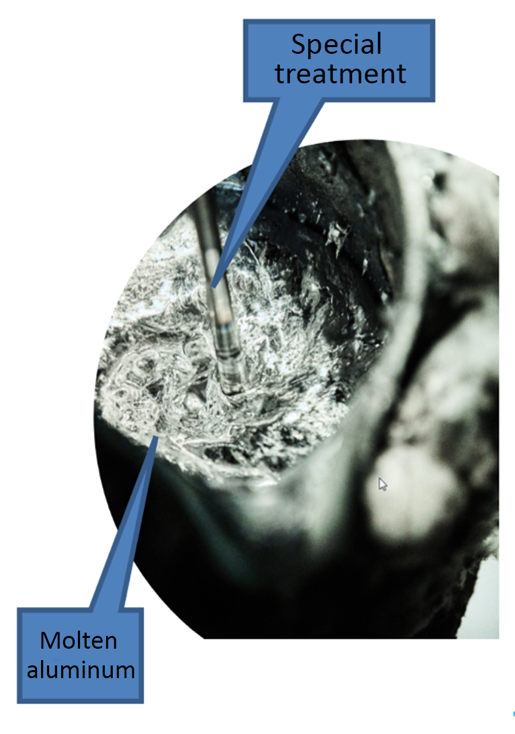

Semi-solid metal casting (SSM) refers to thetechnology where the temperature drops to put the aluminum alloy between itsliquidus and solidus temperature (mushy zone) during its process ofsolidification from liquid to solid. By applying a certain external influencein this phase, the microstructure of the aluminum alloy is presented as aglobular primary surrounded by the liquid phase. In the mushy zone, thealuminum alloy can form certain shapes as a solid piece but flow when extrudedunder a slight external force. The SSM technology completes the die-castingprocess by taking advantage of the properties of aluminum alloys in this state.

Aluminum alloymushy zone: 590-610°C

The potential for forming processes based uponsemi-solid metal alloys was first recognized in the early 1970s at MIT. Aftermore than 40 years of development, it is becoming a mature technology and hasbeen recognized by industries in North America, Europe, Japan, Korea, and otherdeveloped countries. The technology is now widely used in automotive,motorcycle, bicycle, engineering machinery, electronic products, and otherfields for high-end component preparation and production. The R&D of SSMtechnology in China started during the Ninth Five-Year Plan period. After 20years of development, while many in-depth theoretic types of researches havebeen conducted, the industry has not achieved large-scale production with mostapplications remaining in the pilot production stage. Our company teamed upwith Fujian Jiangle Rheocomp Machinery Co., Ltd. in 2020 to carry outsemi-solid metal casting studies and have made some breakthroughs in auto andcommunication applications.

II. Technology Advantages

Compared with the conventionaldie-casting process, the semi-solid metal casting technology has the followingadvantages:

1. The SSM technology can effectively control the blowhole defects in the castingparts. In the process of flow, the semi-solid metal presents an orderly andcontrollable macro-flow state. This characteristic allows the metal fluid tofill the metal mold cavity in an orderly manner as designed, pushing the air inthe cavity to the end of the cavity to be finally discharged through air vent. Itprevents the cavity from retaining air, reduces blowhole defects, and improvesthe density of castings.

2. The SSM technology can effectively control the shrinkage defects in the casting parts. When the metal solidifies from liquid to solid, it has to undergo two volume contraction phases: liquid contraction and solidification contraction. It only takes one volume contraction stage - solidification contraction to change from semi-solid state to solid. Compared with liquid metals, semi-solid metals have a smaller volume shrinkage rate in the solidification process. Under the natural solidification condition, the same volume of semi-solid metal results in less shrinkage in volume than that of liquid metal.

3. The SSM technology can effectively reduce the hot cracking tendency of casting parts. Hot cracking is caused by the internal stress generated in the process of alloy solidification. SSM technology eliminates the internal stress produced during dendrite coherency to reduce the alloy shrinkage and the hot cracking tendency.

4. As high-quality SSM parts are virtually blowhole-free, the castings can undergo high temperature heat treatment to further increase the productivity and improve the weldability of the parts. The SSM technology has retained the characteristics of high efficiency in conventional die-casting production, ideal for the manufacturing components on a large scale. In general, compared with the traditional casting with molten metal, the parts manufactured using SSM technology offer better mechanical performance.

III. Technical requirements for die-casting machines

1. Uniformly accelerated impact-resistant injection start;

2. Adjustable injection speed from 0.05 m/s to 8.0 m/s. Injection repeatability (at steady state) ≤±0.2m/s. Speed overshoot ≤0.2m/s. 20-Stage injection speed control;

3. Directly set injection speed and closed-loop controlled injection speed. Self-adaptive injection process. Real-time automatic adjustments to control parameters reducing or eliminating the need for manual data adjustments by operators;

4. Control to rapid switching from Slow Speed (multi-stage possible) → Fast Speed → Pressure Intensification. The accuracy of switch over position from slow to filling speed is ≤5mm;

5. Minimum opening control of the servo valve to provide reliable safety assurance;

6. Powerful, clear, and accurate injection curve display system. It features: Curve zooming and moving as well as accurate measurement. Curve storing, searching, and printing. Setting and managing reference curves;

7. Extra large memory and PLP for all production management;

IV. Applications

1. Applications in communication industry

As the 5G AUU machine power consumption and single chip power consumption are about 2 times that of 4GRUU, the requirement for unit weight cooling capacity increases significantly. Because of that, the design of the aluminum alloy housing has to improve the heat dissipation capability of the housing by changing the aluminum alloy and increasing the height of the heat sink cooling fins;

Research shows that the lower the silicon content in the aluminum alloy, the higher the thermal conductivity. However, it reduces the fluidity of the molten aluminum alloy and causes warping and cold-flow. The use of aluminum alloy semi-solid casting technology can solve the fluidity issue of the molten aluminum alloy and improve the product quality;

At present, among the major 5G housing manufacturers, many have adopted the aluminum alloy semi-solid casting technology for the production of 5G housing. For instance, Zhuhai Runxingtai uses our 4000-T die-casting machines and Fujian Kinrui Hi-tech uses our 2000/3000-T die-casting machines in the housing manufacturing; 5G products are shown in the picture below:

2. Applications in auto industry

With the increase of automobile ownership every year, automobiles have become the main consumer of petroleum products. To tackle air pollution and other emission problems, China has strictly formulated standards for fuel consumption of passenger cars, and put forward stringent requirements for passenger vehicle fuel consumption and carbon dioxide emissions. Auto makers are striving to achieve energy savings and feul efficiencies by developing new energy vehicles and reducing the weight of automobiles.

Research indicates that for fuel vehicles, a 10% reduction of vehicle weight can increase the fuel efficiency by 6%-8%; if the vehicle weight can be reduced by 100KG, fuel efficiency per 100km will be improved by 0.3-0.6L. For electric vehicles, if the weight of a vehicle is reduced by 10KG, its mileage can increase by 2.5KM.

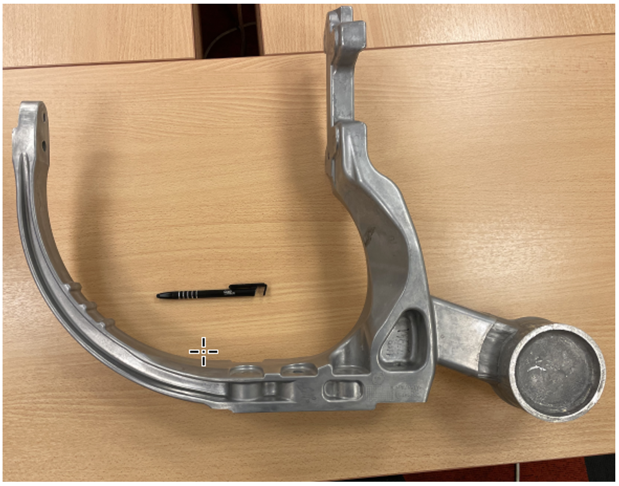

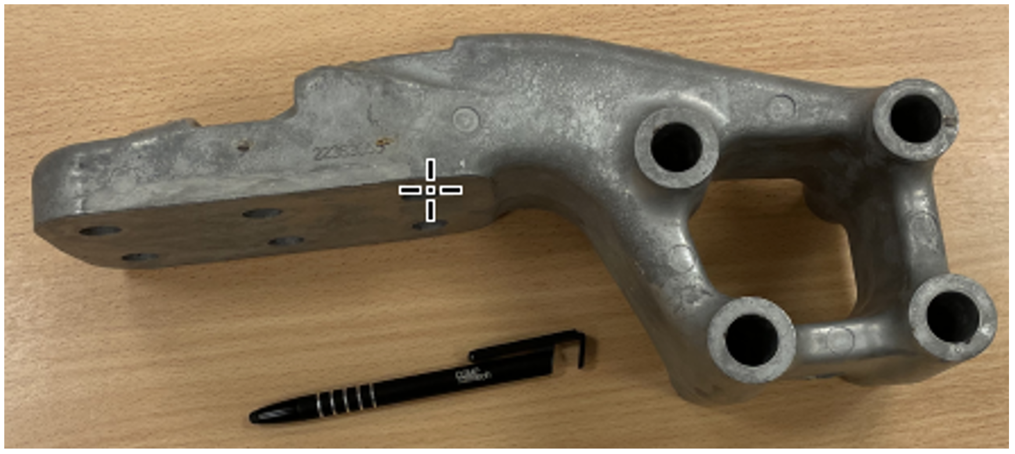

Consequently, replacing steel and forged parts with aluminum alloy in vehicles to achieve weight reductions has become a trend. As the aluminum alloy semi-solid casting technology can satisfy the requirements for product performance, increasing number of auto products are manufactured using the SSM process.

Weight: 9 kg (Replacing gravity casting with a T6 to simplify machining)

Weight: 14 kg (Replacing gravity casting with a T6 to simplify machining)

Weight: 4 kg (Die-casting parts)

* The recorded data are all from the internal test in YIZUMI factory, and the final data please refer to the actual machine.