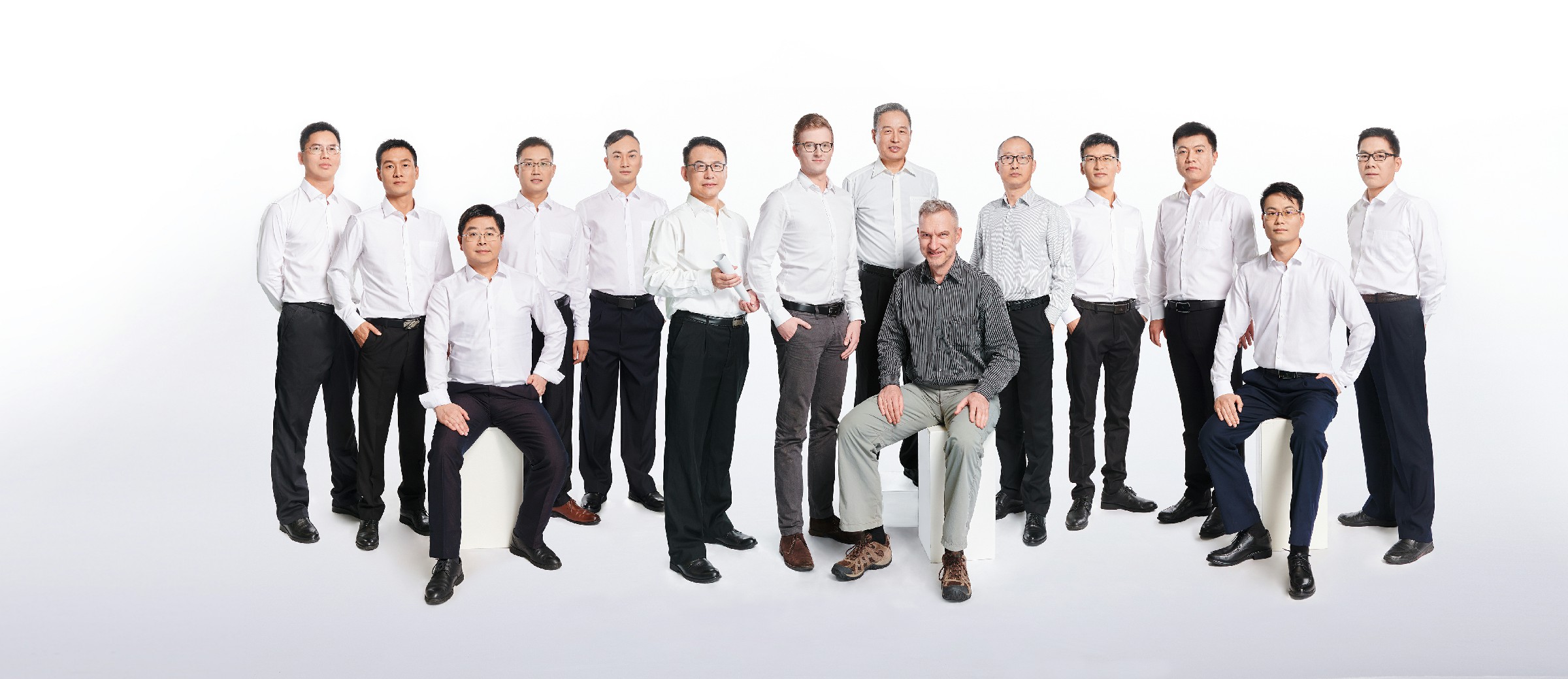

About YIZUMI LEAP——Get to Know Our Engineers...

Abstract:

About YIZUMI LEAP——Get to Know Our Engineers...

The birth of every great product is inseparable from the ingenuity of the R&D team. Every time they move forward, they will spark inspiration, and every cooperation they make will reveal the charm of wisdom. When faced with new challenges, they are not afraid of breaking the boundaries. It is such a group of advanced and excellent R&D engineers who bring us the brand-new product——LEAP Series Die Casting Machine.

"For me to multiply the technology and transfer the knowhow to YIZUMI by close collaboration seemed to be a great project to apply my know-how in a meaningful way."

Working for a German service provider, I was in charge of developing the control system of DCM in a team. I did all the programing and all the necessary algorithms for the innovative 2 stage hydraulic drive unit as well as for the high performance real-time-closed-loop shot control.

YIZUMI had already signed a technical agreement with our team for after sales service in Europe and I was working on our project. So for me to multiply the technology and transfer the knowhow to YIZUMI by close collaboration seemed to be a great project to apply my know-how in a meaningful way.

High-tech made easy I would say. Based on strong team cooperation, we could establish a fantastic control system – ORCA - allowing top casting performance while handling remains easy for the operator due to the intuitive HMI.

Looking back, although the pandemic has made teamwork difficult, the effort and focus of the team and management at YIZUMI propelled me forward to transfer the know-how needed to the team at YIZUMI. Many telcos and personal visits (including quarantine stays) where needed to establish all high-level software and transfer all know-how to my colleagues at YIZUMI. This great experience with a very hard working and capable team in China motivated me tremendously.

————————Timo (Overseas Engineer in YIZUMI LEAP Project)

"Thanks to the whole team! Together we found new solutions how to control movements and pressures in the best way. "

As an engineer from Switzerland, I have fun improving my work continuously. In the past, I have worked for a leading die casting machine manufacturer for 29 years and continuously improved hydraulic and shot end performance for them.

In 2019 YIZUMI was scouting the European market for die casting engineering specialists. I found the YIZUMI focus on achieving a high-performance die casting machine very interesting. The YIZUMI strategy and my own interests are perfectly aligned and so it did not take much time to agree to build a world class DCM made by YIZUMI.

Due to cultural differences between China and Europe, we learned a great deal on both sides. Together we realized a lot of new technical solutions in a rather short time and tested them over a longer period. The verification process was stressful at the beginning. But together we found new solutions how to control movements and pressures in the best possible way.

This time we established a fantastic product with great energy efficiency and top of the line injection performance and repeatability for the YIZUMI brand. We increased system pressure to 210 bar for faster shot reactions and more power during the filling phase; First time in die casting we charge the accumulator during shot completely. The loading starts in 1st. phase and ends in 3rd phase; The servo drive pump unit and the new toggle system design reduces closing and opening times of the die movements.……

I am really proud of our work and the whole team and of our international collaboration.

————Daniel(Overseas Engineer in YIZUMI LEAP Project)

"We choose the most suitable solution for customers to address the challenges in casting manufacturing."

Among the three solutions proposed by the team, we decided to choose the most challenging but the most effective one that is both, suitable for customer’s requirements and adding a professional design to our new product. Working closely with suppliers and experts on sheet metal projects, we were able to carry out this solution. Throughout the process, we maintained our focus on the longevity and durability of our new DCM----- the important factors that influence the customer’s ROI.

During the whole project, the Chinese team members have been able to discuss problems (and solutions) with European experts in a more timely and direct manner and constantly adjust the product as needed. From the very beginning, members have paid special attention to details and proactively eliminated downstream problems, which would help increase machine uptime. Cooperation with European partners provided our team members with opportunities to improve their working ability, skills and knowledge, and widen their international perspective.

——————YIZUMI Product Management Team

"From design, production to finished product, it is a complicated and challenging process."

Because none of us communicated in our mother tongue, there were some difficulties in understanding. Especially when expressing technical terms, a simple word in Chinese or German may require a detailed explanation in English, and it may finally not be understood. Thus, we needed to look through dictionaries and English academic journals, accumulate vocabulary to remove language obstacles.

During the academic discussion, I realized the differences in the product concepts between the two sides. Instead of plunging into solutions and getting lost in product goals like we used to do, the overseas engineers will identify the customer needs first. After a series of brainstorming sessions, they began to make process analyses, clarified the objectives and technical requirements, and then selected the goals and next steps. Finally, a precisely designed solution is carried out. I see the rigorous and meticulous craftsmanship spirit in them.

Taking a design into production and turning it into a product is a complex and challenging process, and I am honored to be a part of this interesting project. The new generation LEAP series provides an upgraded and optimized injection system, control system, clamping system, etc. We believe that it can bring more value to customers in the field of industrial application.

————————Domestic Engineer In YIZUMI LEAP Project Zhang Dunji