Biofibre is a mid-sized compounder for biopolymers and biocomposites, based near Munich in Germany. The offering are bioplastic compounds tailor-made for several applications and processing technologies. In 2020 the compounding capacity was increased. Since then the company is constantly looking for new applications and partnerships to sustainably grow the business. The main focus is on biobased, biodegradable compounds with natural fiber reinforcement. One of the really successful projects, called EcoSpacer, was for example honored with the Biopolymer Innovation Award in 2019, where the wood-fiber filled compostable compound Silva was used to separate concrete labs.

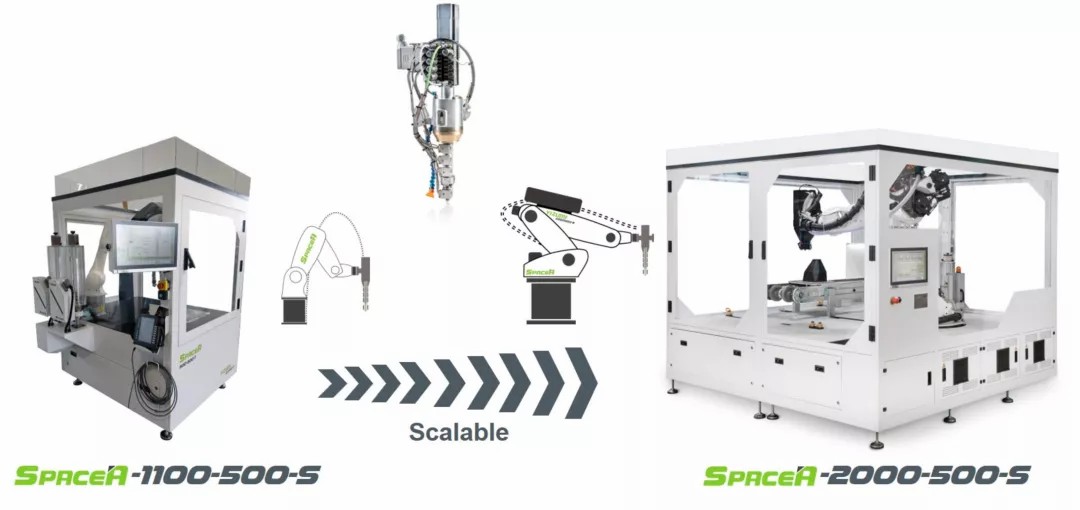

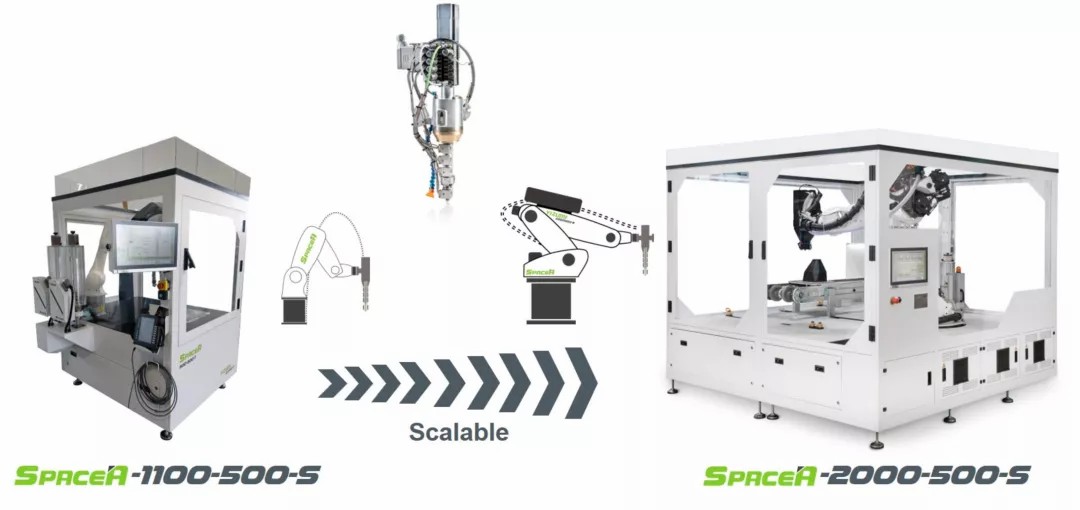

For the present project Biofibre partnered with Yizumi Germany. Both companies have set a similar target, i.e. to grow sustainably with smallest impact on nature as possible. For their 3D printing business with the machine concept of Yizumi, named SpaceA, energy reduction and fast production cycles are core. By the use of the energy efficient additive manufacturing a small to midscale production can realized in a simple, fast and competitive way compared to other additive manufacturing and established plastic processing processes. The 6-axis-robot of the printing cell allows moving the core part, which is a screw extruder. Thanks to the large build volume SpaceA allows a production of large scale plastic parts. The main advantage of the use of a screw extruder in 3D printing is the option to process conventional plastic resin. In comparison to the use of very expensive filaments, it can reduce costs on one side but also allows the utilization of highly filled and fiber reinforced compounds. The optional use of a conveyer belt leads to a machine system set-up which is able to print parts non-stop. Such a complete manufacturing cell is able to work on a level of 0.8 kWh/kg Material Throughput, which is a at least already for the forming process a good value. Additionally, using 3D-Printing technologies saves resources due to less demand in mold design and mold making and finally, also common 3D-Printer needs less resources to be produced, especially compared to big primary forming machines.

Yizumi SpaceA

The partnership of Biofibre and Yizumi Germany grew after very promising trials. The printing of Silva SI2900 showed a large processing window compared to other compostable plastics. Furthermore a good printability compared to other fiber filled plastic compounds was experienced. In comparison to other compostable compounds no fast degradation during processing was observed. The visual impression of uncolored printed surfaces of Biofibre Silva looks wood-like with a silk matt surface. The mechanical performance is comparable to stiffer polypropylene (PP). Depending on the die diameter the material offers space for a wide range of individual part designs.

With the processing and performance profile shown in these initial printing runs the team discussed about potential applications. One of those ideas is the processing of a flat and large sized mesh structure. This mesh is intended to be used as protection of seeded plants against animals who like to eat its sprouts or young leaves. This size of mesh protection is typical for the used as protection in vineyards after planting new wine grapes. In an unrolled form this mesh sized up to approx. 700 mm x 400 mm, which usually requires large molds and therefore also large primary forming machine technology. Using SpaceA-Technology also means that you can size up the mesh dimension easily, only by changing the CAD-Data and you can start the production instantly.

Side wall of a printed part made of Biofibre Silva SI2900

It is known that the production of those mesh structures in injection molding is quite challenging. Only very easy flowing polymers without fillers can be used to fill the mold. In opposite to that a production based on an extruded flat sheet which is trimmed afterward is quite complicated. Especially with the limitation on biodegradable plastics both technologies are tough to realize for this mesh dimensions. Biodegradable polymers lack either of mechanical stiffness or suitable elongation. Summarizing, for injection molding the flowabilty of compostable compounds is one limiting factor. On the other hand the use of a suitable reinforcement has distinct limitations to the flat sheet extrusion technology as well. Overall Yizumi’s SpaceA additive manufacturing technology provides a good production method for this flat mesh structure in the needed dimensions for wine grape applications. In combination with the 20% wood fiber reinforced Biofibre biopolymer, the material provides a combination to produce a mechanical stiff mesh structure which is still bendable enough for this application. Furthermore, through the inclusion of natural fibers the biodegradability may be tuned.

Plant protection printed with Biofibre Silva SI2900

After adjusting the processing speeds and needed temperature profiles, the print took 3 minutes to produce one part. To simulate a continuous production printing took place directly on a conveyor belt. Tests running with wine farmers showed that the parts were easy to apply and very resistant to provide sufficient protect already against rabbits and hares due to the tailored design and the inherent mechanical properties from the biocomposite material.

Additionally, for furniture applications, where thick wall dimensions and high mechanical stiffness testify to a high value, Yizumi invented the use of chemical foaming within the 3D-Printing process. By means of this technique it is possible to reduce the part weight up to 40 % and create lightweight parts with high mechanical properties. Therefore, it is possible to create parts with an additional resource saving approach. Due to the smart extruder design, it is possible, just to integrate the foaming agent as a masterbatch, like we do with color masterbatches as well. This leads to a homogeneous foamed melt strand, which leads to a unique surface appearance.

In summary this application of a plant protection shows that the clever combination of new biomaterials and innovative machine technology open up new potentials for part designs. Joint efforts are currently spent on furniture applications.

Plant protection printed with Biofibre Silva SI2900

After adjusting the processing speeds and needed temperature profiles, the print took 3 minutes to produce one part. To simulate a continuous production printing took place directly on a conveyor belt. Tests running with wine farmers showed that the parts were easy to apply and very resistant to provide sufficient protect already against rabbits and hares due to the tailored design and the inherent mechanical properties from the biocomposite material.

Additionally, for furniture applications, where thick wall dimensions and high mechanical stiffness testify to a high value, Yizumi invented the use of chemical foaming within the 3D-Printing process. By means of this technique it is possible to reduce the part weight up to 40 % and create lightweight parts with high mechanical properties. Therefore, it is possible to create parts with an additional resource saving approach. Due to the smart extruder design, it is possible, just to integrate the foaming agent as a masterbatch, like we do with color masterbatches as well. This leads to a homogeneous foamed melt strand, which leads to a unique surface appearance.

In summary this application of a plant protection shows that the clever combination of new biomaterials and innovative machine technology open up new potentials for part designs. Joint efforts are currently spent on furniture applications.

Homepages:

https://biofibre.de/en/

https://www.yizumi-germany.de/en/

Authors:

Dr. Nicolai Lammert, Head of Additive Manufacturing, Yizumi Germany GmbH, Alsdorf, Germany; n.lammert@yizumi-germany.de

Christoph Glammert, CEO Biofibre GmbH, Altdorf, Germany; christoph.glammert@biofibre.de

Jörg Dörrstein, Head of R&D Biofibre GmbH, Altdorf, Germany; joerg.doerrstein@biofibre.de