IMC Molding Solution for Auto Side Door Panel

D1-E Series Hybrid Injection Molding Machine

UN500D1-E hybrid injection molding machine adopts a two-platen clamping unit and an electric-driven injection unit, combined with the special mold for IMC panel and robots to embed inserts (circuit boards) and extract products, to provide integrated solutions for customers in the development of new products for auto parts, home appliances, and 3C electronics.

Highlights

01 Eco-friendliness

Low VOC emissions during processing, low carbon and environmental protection.

02 Self-healing material

Self-healing when scratched, maintaining bright and fresh appearance.

03 Adjustable softness/hardness

Rapid and efficient one-step molding. Adjustable softness and hardness, ranging from silicone softness to 3H hardness.

04 High transparency and glossiness

High transparency, high glossiness (91˜93%), curing temperature of 75℃, without high-temperature inhibitors, and no yellowing or whitening. PUR material can replicate the mold surface with high glossiness perfectly.

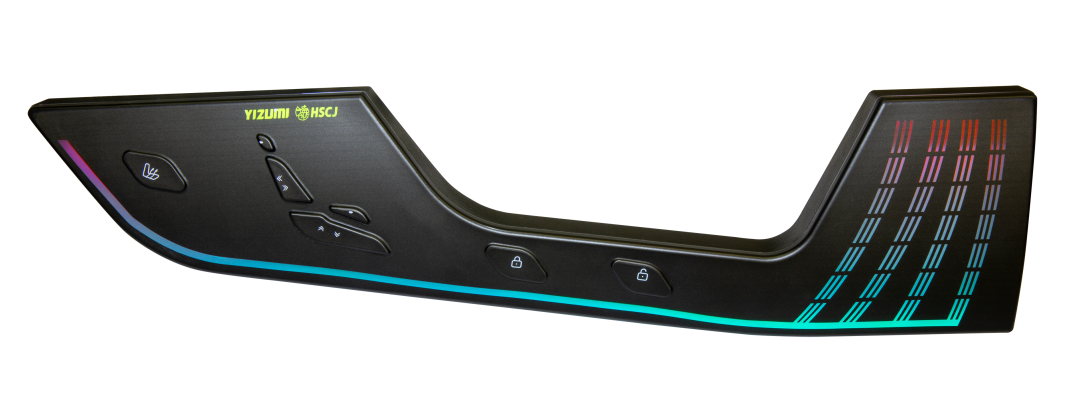

Application Case

Product: IMC panel for auto side door

Number of cavities: 1

Size (L*W*H): 456*125.1*20mm

Material: ABS+PC+PUR

Weight: 105g

Cycle time: 130s

*The data above were acquired by testing in the factory, only for your reference. As to the specific data, please refer to the actual equipment.