IMC Molding Solution for Auto Side Door Panel

D1-E Series Hybrid Injection Molding Machine

UN500D1-E hybrid injection molding machine adopts a two-platen clamping unit equipped with an electric-driven injection unit. Combined with the special mold for IMC panel, the machine employs robots to embed inserts (circuit boards) and extract products, providing integrated solutions for customers in the development of new products for auto parts, home appliances, and 3C electronics.

Highlights:

1. Adopted with two-platen hydraulic clamping unit and electric-driven injection unit to make production more energy saving, high efficiency, precision, stable, sound proof, and green.

2. Hydraulic technique combined with pure electric technology, efficiently integrating different mechanical units through modularization while retaining their advantages.

3. Provide turnkey solution for intelligent film application for high-end plastic product.

4. Adopts the special clamping control technology with two-phase mold closing function, offering higher level of uniform holding pressure, improved product surface quality and density, and better solutions to overcome product warping problem. This machine family can also expand the injection-compression molding and injection-breathing molding process that can be applied to products in automotive, 3C, home appliances, and medical industries.

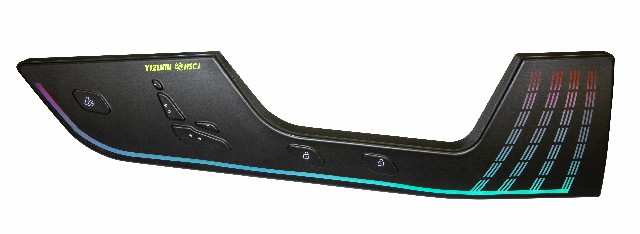

Product: IMC Panel for Auto Side Door

Cavity: 1

Material: ABS920

Size (L×W×H): 456*125.1*20mm

Weight: 80g/pc

Cycle time: 90s

Partner: HESHENG CHUANGJIE (Mold)

* The Data above were acquired by testing in the factory, only for your reference. As to the specific data, please refer to the actual equipment.