HII-S Series Cold Chamber Die Casting Machine

Abstract:

Process-performance-enhancedYIZUMI die casting machine as a result of a close collaboration between theYIZUMI R&D team and European engineering experts. Improved injectioncapability, significantly higher casting repeatability and increased shot-control-precisionprovide you with an advanced manufacturing solution. Competitive Technology atfair prices.

HII-S Series Cold Chamber Die Casting Machine

DM180HII-S - DM900HII-S

Specially Customized for Global High-end Die-casting Part Manufacturers

High-performance Product Line Customized for Global Markets

Suitable for various industries, including high-end auto parts, communications, rail transport

HIGHLIGHTS

1️⃣ The Pressure Build-up Time Shortened by 30%

Further improved pressure build-up time by over 30%. The HII-S pressure build-up time offers great performanceto any casting process.

2️⃣ Precision Improved by 20%

The HII-S provides a high standard of precision to switch-over to the cavity filling phase. A repeatability of max +/-2mm satisfies the highest requirements.

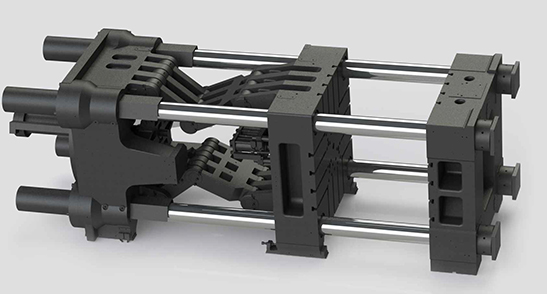

3️⃣ Clamping Unit

Shorter cycle times and increased platen rigidity significantly improve customers production output

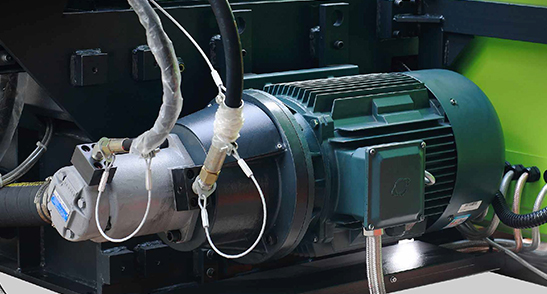

4️⃣ Upgraded Injection Unit

Increased casting process consistency for our customers based on successful international engineering cooperation.

5️⃣ Fast and Precise-Hydraulic Drive System

The hydraulic system can precisely keep the balance between energy consumption and efficiency to enable faster cycle times with minimal energy consumption, and effectively increase the productivity and meet customers' higher OEE expectations.

6️⃣ International Standard Electrical Control System

High level design complying with worldwide safety standards.

Based on technology data entry the YIZUMI H II-S control system calculates critical casting process data to support process engineers.

GENERAL TECHNOLOGIES

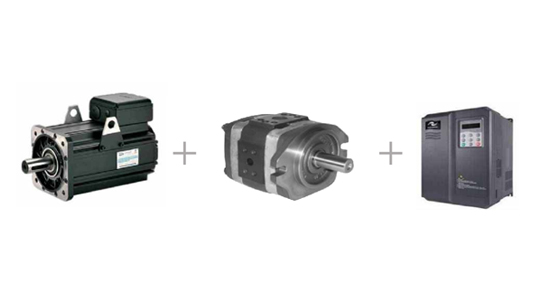

1️⃣ The Third-generation Servo System (Optional)

Low Noise:The third generation servo drive offers even lower noise emissions if compared to the previous design. System noise reduction of about 20%.

Enhanced Power: Stabilizing power surges automatically for up to 5 min, this system offers great operational stability even with fluctuating main power.

Faster Response Time: Reduced system response time improves reaction time and highest operational performance.

Energy Saving: This efficient servo pump system ensures lowest possible oil temperatures, further enhancing operational efficiency.

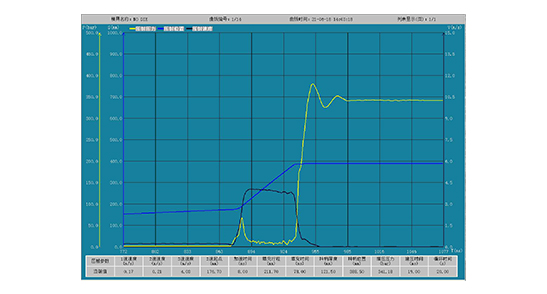

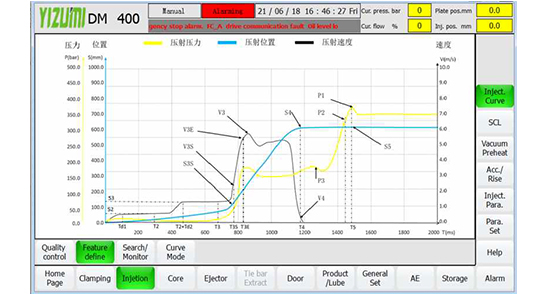

2️⃣ Quality Control System (Optional)

Position, Pressure & Speed Curve Display and Intelligent QC Technology

Efficient Process Monitoring.

High-precision injection curves are displayed in real time.

Master Curve Function.

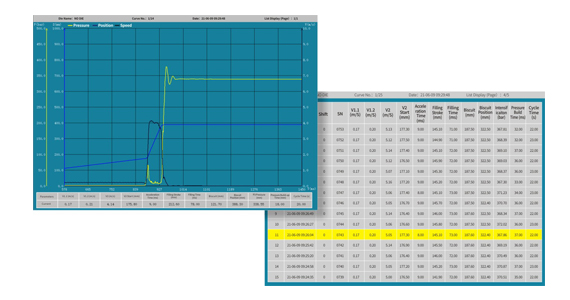

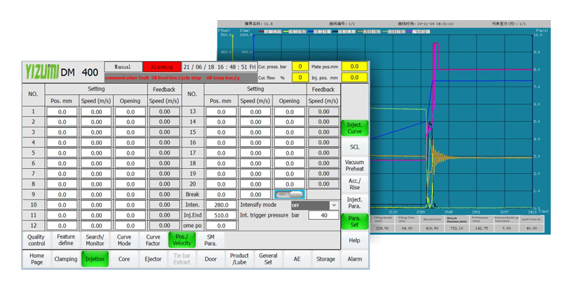

3️⃣ Real-time Closed-loop Control (Optional)

YIZUMI Real Time Closed Loop Shot Control (RTCL) Highest Standard of Injection Performance in Real Time.

RTCL in all Injection Phases:Our enhanced RTCL shot control system ensures highest injection repeatability across all injection phases. A reliable shot control from YIZUMI for advanced products and highest precision. including automatic correction of process parameters.

Pressure and speed real time control: Real-time closed-loop control systems ensure quality consistency over long periods of time.

※The above data is obtained by in-plant testing and inspection for your reference. The specific data is determined according to the actual measurement of the equipment configuration.