Thick-Wall Lens Molding Solution

UN700D1M Two-Platen Injection Molding Machine

During the CHINAPLAS, YIZUMI's UN700D1M two-platen injection molding machine will demonstrate the solution for molding thick-wall lenses on-site. This solution utilizes two injection units and six stations to achieve one-shot molding. While ensuring product transparency, the maximum thickness of the product reaches 19.5mm. The molding cycle has been reduced from the original over 400 seconds to approximately 60 seconds, resulting in an 85% increase in production efficiency. A four-axis robot is employed for part retrieval, followed by laser trimming of the sprue. Subsequently, visual inspection is carried out to detect product defects and assess the quality of sprue trimming. Approved products are then packaged and boxed.

Value Advantages

01 Performance: Utilizing a 6-station servo turntable structure with two injection units for servo injection, enabling 360° continuous rotation.

02 Value Proposition: The primary value lies in its remarkably small footprint, achieving two-color 6-layer one-shot injection molding . The unique molding process results in a short cycle, significantly increasing production efficiency for customers.

Product

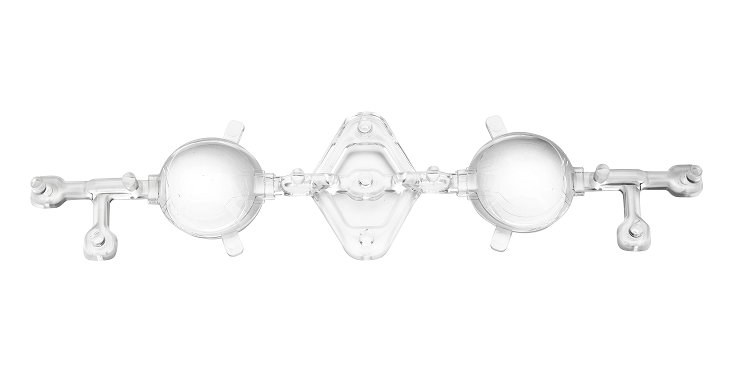

Thick-Wall Lens

Material: PMMA

Number of Cavities: 2

Weight: 96g

Thickness: 19.5mm

Cycle time: 60s

*The data above were acquired by testing in the factory, only for your reference. As to the specific data, please refer to the actual equipment.