The Official Opening of YIZUMI New India Gujarat Factory

Abstract:

On October 7, the opening ceremony of YIZUMI new India Gujarat factory (shortened as new India factory) was held in Ahmedabad, Gujarat, India. A great number of people came to attend this grand ceremony, including Indian government leaders, industry experts, customer representatives, friendly Chinese companies in India, and employees of new India factory.

On October 7, the opening ceremony of YIZUMI new India Gujarat factory (shortened as new India factory) was held in Ahmedabad, Gujarat, India. A great number of people came to attend this grand ceremony, including Indian government leaders, industry experts, customer representatives, friendly Chinese companies in India, and employees of new India factory.

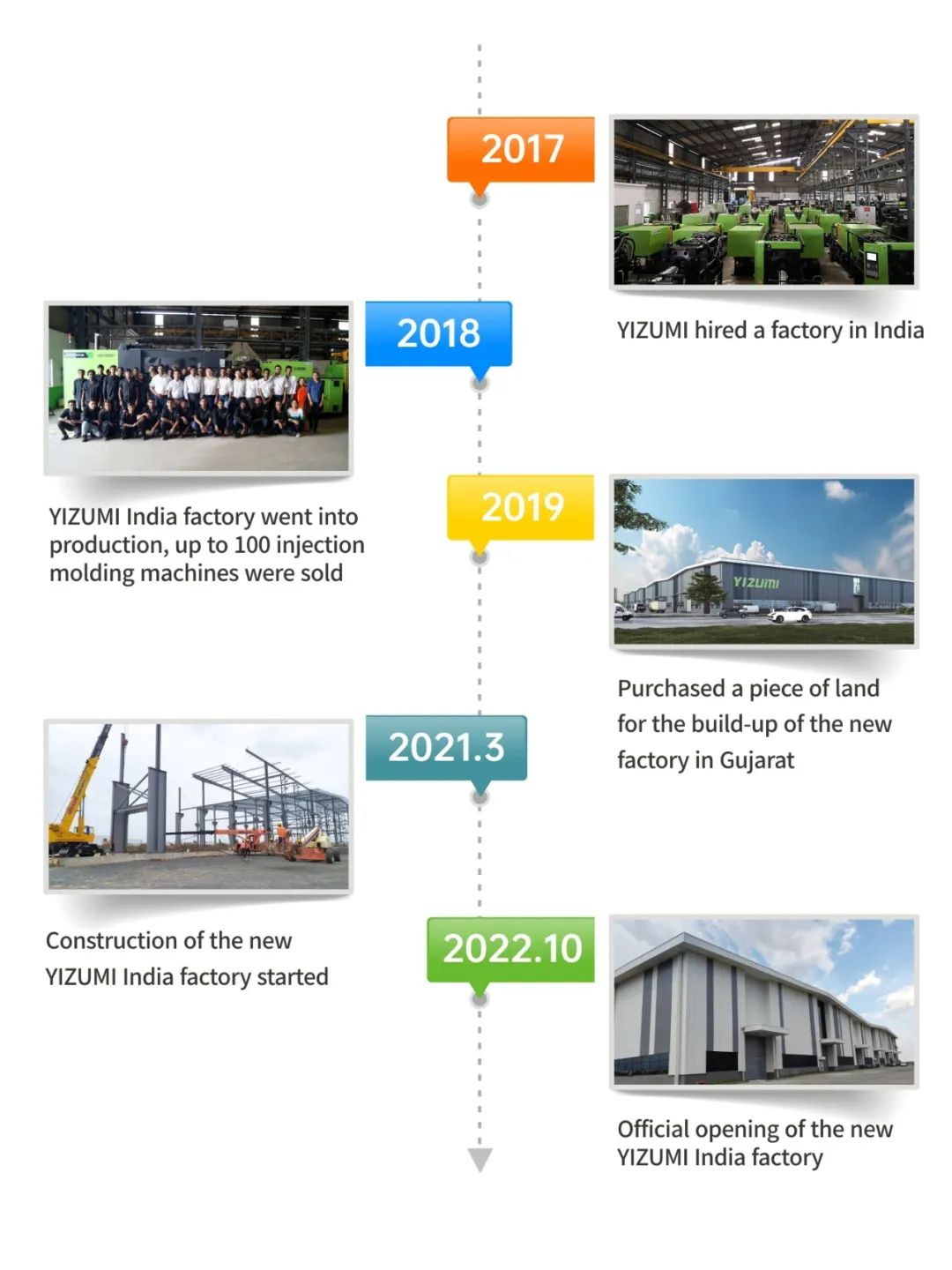

YIZUMI purchased a piece of land in India to build its own modern factory in the middle of 2019 and the construction started in March of 2021. After around 40 months of preparation and construction, the first phase of the factory will be officially put into operation in October 2022. The total floor area of the factory exceeds 20,000㎡.

It is reported that the new India factory is designed and built as a modern manufacturing factory with full reference to the standards of YIZUMI’s headquarters. The factory has the capacity to better meet the needs of Indian market with some particular functions such as customization and development of non-standard requirements, parts manufacturing, complete machine assembly and commissioning, as well as customer service and training.

With the support of the new India factory, a professional team of Chinese and Indian engineers will provide Indian customers with faster product delivery, higher quality products, and better after-sales service. Its successful completion also demonstrates YIZUMI’s strong determination of long-term development in Indian market.

In this regard, Mr. Zhang Tao, the deputy managing director of Guangdong Yizumi Precision Machinery Co., Ltd. (“YIZUMI”) and general manager of the injection molding machine division said, “As an important production base and customer service platform built by YIZUMI outside of China, the new India factory will provide high quality products and comprehensive services to Indian customers, enhance YIZUMI’s overall competitiveness in the Indian market, and radiate to the surrounding countries and regions, driving the expansion of YIZUMI’s injection molding machines in South Asia, Central Asia, and Africa.”

Steady growth in overseas markets

India has become the largest single overseas market for YIZUMI

With the landing of its globalization strategy, YIZUMI is changing the landscape in the global equipment manufacturing field. YIZUMI’s overseas market continues to grow steadily, accounting for more than 20% of its annual sales. As the operation in overseas markets gradually reveals its potential, YIZUMI India factory is playing an increasingly important role.

Attracted by the huge growth potential of Indian market, YIZUMI has taken aggressive action to develop and made self-adjustment to better meet Indian market demands. Since 2017, YIZUMI has been manufacturing and selling injection molding machines in India in a leased facility. With its outstanding product quality and cost advantages, YIZUMI has quickly established a good reputation in the Indian market. The factory has been developing new customers while receiving many additional orders from existing customers.

As of September 2022, the number of injection molding machines manufactured and sold by YIZUMI India factory has reached 1,500 units, making India the largest single overseas market for YIZUMI.

With the business expansion of YIZUMI India factory in recent years, the capacity of the leased factory has been unable to meet the rapidly growing market demand, even constraining the growth of YIZUMI in India. Given its global strategic layout, YIZUMI acquired land in Gujarat, India to build its own modern factory.

Talking about why YIZUMI chose India to build a factory, Mr. Zhang Tao explained, "It is primarily based on the strong confidence in the continued growth of the Indian market. We also strive to take YIZUMI’s business to the next level by seeking more close and in-depth cooperation with the upstream and downstream local industry chains in India, so as to understand the needs of customers in various industries and provide targeted localized solutions and high-quality services.”

With the technical and management support from the headquarters

Phase I factory can manufacture 2000 units of injection molding machines annually

The new India factory is located in the GIDC Industrial Park in Gujarat, adjacent to Mitsubishi Electric, and covers an area of 80,000 square meters. It is planned to be completed in two phases. Upon the completion of Phase II, the factory will be able to meet an annual output demand of Rs. 10 billion.

The Phase I factory completed recently is 20,000 square meters in size and will be used for manufacturing SKII and A5 series three-platen servo hydraulic injection molding machines, DP/D1 series large two-platen injection molding machines, and PAC series high-speed packaging machines for Indian market. It has an annual output capacity of 2,000 units of injection molding machines with a maximum clamping force of 4,000T.

The new India factory is equipped with large overhead cranes, automatic lubrication systems, circuit systems with a high factor of safety, complete fire protection systems, and industrial fans. The entire floor space is paved with floor coating and equipped with enclosed painting and powder coating booths. The factory area is well planned, creating a comfortable operating environment with neat and clean work conditions for the employees in India.

In terms of the management system, the manufacturing capacity of the new India factory is fully supported and managed by the leading digital lean manufacturing system of YIZUMI headquarters. The new India factory complies with the global unified manufacturing process and quality management standards of YIZUMI products. Meanwhile, it further optimizes the manufacturing and management with the actual situations accordingly to develop a high-quality and fast delivery capacity for Indian customers.

In this regard, Mr. Zhang Tao said, "We need to have an accurate understanding of the performance parameters and functional requirements of various industries in India for injection molding machine products, know the differences in the operating habits and make targeted improvements and upgrades to our existing products, to better meet the needs of Indian customers.”

Contributing to the steady progress of globalization layout

Establishing a close collaboration with the headquarters in China

India is one of the most important overseas market for YIZUMI. The company has been deeply involved in this region for 14 years since it made the first sale in India in 2008. YIZUMI India factory integrates Chinese and Indian management styles by combining the existing management concepts and approaches with Indian culture and operating the factory with innovative thinking.

At present, YIZUMI has established a marketing and service network covering all major plastic processing and manufacturing industries in India and has become a well-known injection molding machine manufacturer and service provider in the Indian market, providing products and technical support to customers in various industries such as automotive, home appliances, 3C, medical, packaging, and building materials.

In recent years, following the steady progress of its global strategy, YIZUMI’s Aachen R&D Center and Technical Center in Germany, Vietnam Technical Center have landed one after another, signifying that YIZUMI’s globalization layout has taken another firm step.

The new India factory is an important production base and customer service platform outside of China. YIZUMI builds it to the front line of the market to establish closer ties with Indian customers, provides higher quality products and services, improves the overall competitiveness of YIZUMI in the Indian market, and creates a new pattern of close collaboration between overseas subsidiaries and the headquarters in China.

As Mr. Zhang Tao emphasized, “The completion of the new India factory marks a new starting point. YIZUMI will continue to create more value for customers with better quality products and more convenient services through innovation in technology, service, and management. Meanwhile, YIZUMI will grow together with our customers, employees, and partners for win-win development!”