【K 2019】Yizumi to debut the DCIM process in cooperation with Exipnos

Abstract:

【K 2019】Yizumi to debut the DCIM process in cooperation with Exipnos

Yizumi solution: UN160A5-EU high-end servo IMM + CDS (Compound Delivery System) + Yizumi linear robot system YR6308S

|

1) Time savings. DCIM does not require any granulation. This eliminates many time-consuming process steps. 2) Energy efficiency. Because the compound does not have to be heated, dried and transported, up to 0.4 kWh of energy are saved per kilogram of material. 3) Cost efficiency. Minimal process and energy costs result in cost advantages of up to 50 cents per kilogram compared to conventional processing. 4) Quality benefits. The gentle, continuous processing often leads to materials with higher quality properties compared to conventional production with the same material composition. 5) Flexibility. Because the finely tuned, automated dosage of the material components takes place "live" on the injection molding machine, mixing ratios can be monitored and corrected in real time. This enables the converter to make tailor-made parts for his customer. 6) Fast ROI. DCIM unit is a modular system with solid construction. The DCIM unit can be docked with existing injection molding machines and can be switched on and off as required. The investment is therefore limited. |

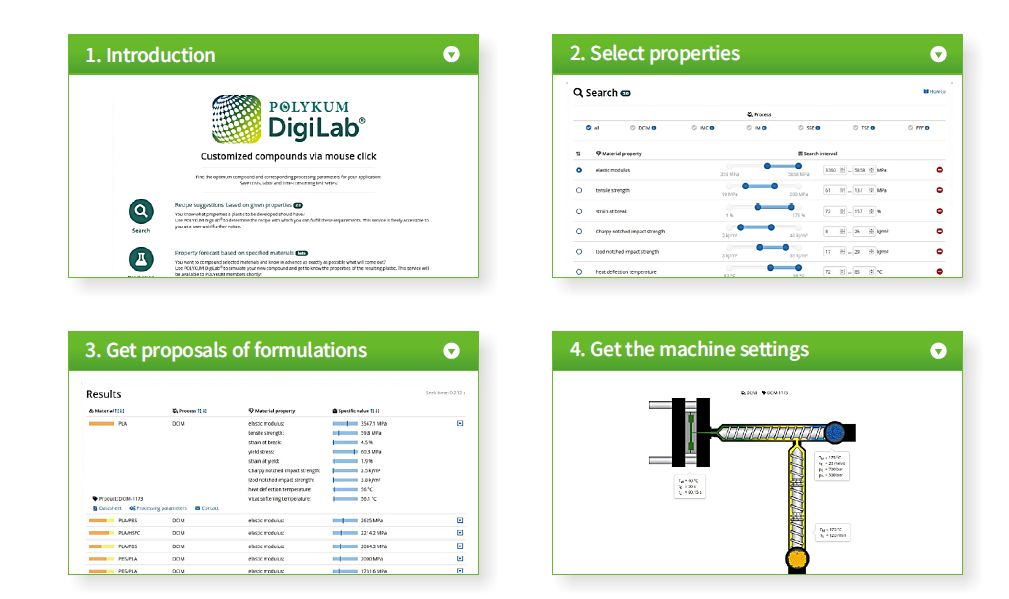

Compound Check: Limitless opportunities for innovative processors

Exipnos GmbH is a research-based and specialty-producing company in the plastics industry (certified according to DIN EN ISO 9001: 2015), which have been using fully functional DCIM prototypes for compound research and development for years. The customers thus benefit exclusively from the extensive experience and advantages of this technology.

In order to develop all advantages for innovative processors in the long term, Exipnos offers a compound check to interested customers. These fast, reliable results are made possible by the direct compounding technology, which eliminates the time-consuming and expensive granulation of material samples.

For DCIM customers, Exipnos can prepare the formulations and molding conditions of the materials and check the requested properties. The lab can test nearly all possible properties and then find the right formulation that enables the customer to produce the high quality parts.

The Yizumi DCIM solution will make live demonstration at Hall 12 / A27 of Dusseldorf Exhibition Center.

Application Example

Yizumi at K 2019:

IMM booth: Hall 13 / D80

DCIM solution: Hall 12 / A27

Rubber Machine booth: Hall 14 / C59