Imitate "unmanned factory", YIZUMI create a full automatic die casting cell test platform

Abstract:

Imitate "unmanned factory", YIZUMI create a full automatic die casting cell test platform

In YIZUMI, there is a full automatic die casting cell test platform which is Independent of the die casting production workshop, here the die casting machines and the robot is not used to sell but for the testing. At the beginning of the end of 2015, YIZUMI opened up a more than 300 square meters space to build the test platform which is used to test the new design, host performance spare parts, ect. Only for the full automatic die casting cell test platform, YIZUMI have invested around ten million, it is rare to have the scale and advanced test platform in the die casting industry.

Update test platform to escort the machine

Test is an important link in the production of die casting machine, when researching and developing new products and new components, the problems can be found in advance and can reduce the occurrence rate of fault in customer site, more importantly, the test data report can provide the valuable reference for the improvement of machine performance.

Last year, the second phase of WUSHA factory has went into production line, so the available production area for die casting machine were increased significantly. In order to improve the testing level, YIZUMI liberated the testing from the manufacturing workshop and separately to build the test platform which was started to be used in January this year.

“Testing time in workshop is more limited, when the production task is more urgent, the test will need to concess." said by the test team leader of product research and development department Liao Bin. Test need enough time and short time is half of a day or as long as 2 months or even half a year. Because the testers need to know the status of new machines or parts which are under a long time running.

Establishing the test platform can ensure adequate testing time. The action time, cooling effect, stability, operation and maintenance convenience and so on, testers can get more data on the platform through the test instrument. More importantly, with the establishment of the test platform, test level of YIZUMI has also been improved, test methods, tools has become more and more rich and advanced, the harvest of the information was more diverse. According to reports, the test platform will purchase a IMC tester which value around 200 thousands yuan and it will used to detect host pressure, flow, etc.

Today, in the test platform, in addition to a full set of automated robot linkage DM1650, also there were superior series 800T, 300T machine which are launched the market last year "The superior series is a new model that was introduced last year. We hope to continue to test and improve the performance of the machine."

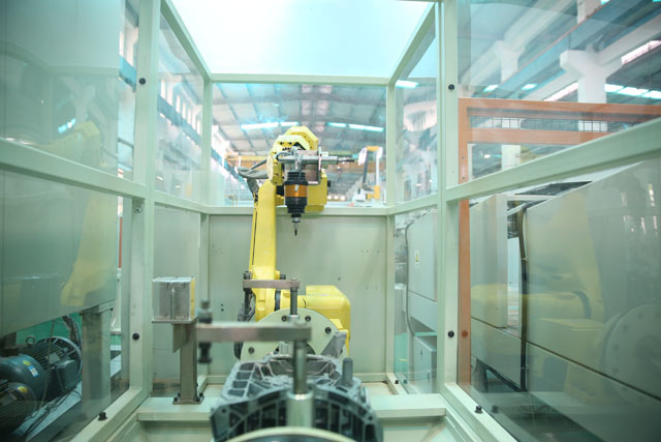

Experience in full automatic die casting production line

In addition to used for machine testing, the testing platform is also the platform of the full automatic die casting cell. It equipped with 1650T die casting machine and also installed the automatic ladle, FANUC robot sprayer, extractor and deburrer. Imitate "unmanned factory", to realize the automatic ladling, products extracting, product integrity testing, product cooling, cutting, deburring and products output, customers can observe the future direction of development of die casting industry.

The general manager Doufeng of YIZUMI automatic robot said: “it is not difficult to realize the action of extraction and spraying in robot .Currently, there are many robot automation enterprise which have the relevant conditions but to realize the full automatic die casting production process, it need to be very know and familiar with the production process of die casting, at the same time should be strong strength in system programming and custom design."

YIZUMI core technology engineer has more than 10 years of experience in die-casting robot automation industry, they have served on famous die casting supplier such as TOYOTA, Honda, Nissan and other well-known enterprises, so the plan, design, debugging and running can ensure that consistent with the international first-class level.

By virtue of the leading design, the robot automation system have loaded more than the value 30 million, compared to 2014 ,the sales has grown more than 400%, the performance is expected to double this year.