YIZUMI to present innovativetechnological solution: “PUR+IM+3D printing”

Abstract:

YIZUMI to present innovativetechnological solution: “PUR+IM+3D printing”

CHINAPLAS 2019 will be held at China Import & Export Fair Complex,Guangzhou, China from 25 to 29 June 2019. At this year’s show, Yizumi will bring a new technological solution: "PUR + injection molding + 3D printing" one-step molding. It not only breaks through the bottleneck of the traditional coating process in application, but also presents a new direction for manufacturing enterprises.

Debut of the ReactPro polyurethane in-mold coating molding solution

Products of the polyurethane material can achieve high quality appearance (high-gloss surface), and features corrosion resistance, scratch resistance, self-repair. Therefore, polyurethane coating is attracting more and more attention from automotive manufacturers, and is gradually applied to the production of automotive interior parts such as dashboards, center consoles, door panels and more.

For the automotive industry application needs, Yizumi will present ReactPro polyurethane in-mold coating molding solution at this year's CHINAPLAS: Yizumi UN500DP two-platen injection molding machine integrates PUR equipment, coupled with InPUR "1 + 2" mold technology, one-step molding engine cover with partial high-gloss surface effect. Compared with the traditional coating process, ReactPro reduces the molding steps of the product, greatly saves cost and avoids environmental pollution caused by coating.

Yizumi’sReactPro is mainly used in the upgrading of automobile interiors (dashboards, door panels, A/B/C/D pillars, etc.), bringing along better texture and showcasing a higher-end premium quality. Simultaneously, there are also unlimited potential in the fields of 3C and home appliances.

More importantly, the solution will accommodates the SpaceA flexible additive manufacturing system, “printing” a layer of sealing structure for the engine cover. Additive manufacture technology (commonly known as "3D printing") has been used in production of sample parts, and even has a certain competitive relationship with the injection molding process. Now the combination of the two technologies will provide a new application space for enterprise manufacturing.

Innovative new solutions of the Yizumi Pro Series

At the same time, several "Pro" applications of Yizumi released last year will also be unveiled again this year, bringing new technologies and products.UN550C-BTP, a wide-platen, high-end, multi-material injection molding machine equipped with “smart compensation technology for molding defects”, “precise positioning technology for servo turntable”, “low-speed control technology” will produce two-color taillight cover on site, providing a set of more cost-effective option for stable molding and customization of lights cover in automotive industry.

In the field of thin-wall packaging products, Yizumi positioning has become the best cost-effective system supplier. PacPro thin-wall packaging product molding program will focus on IML in-mold labeling, with the new PAC200 model, Yizumi a four-circle container mold, and IML automatic labeling robot, high-efficiency molding a four IML round container. Compared with last year's four-cavity IML plastic cups, it will once again increase the efficiency of thin wall molding in the industry.

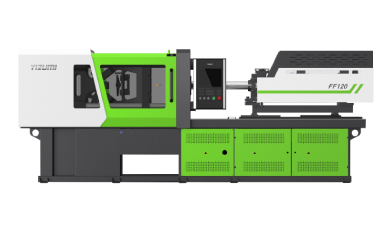

Additionally, Yizumi will also present its small and medium precision medical device injection molding solution. Yizumi FF120 electric injection molding machine, equipped with Servo Direct Control, a latest R&D achievement by Yizumi will demonstrate production of medical blood tube filter(8-cavity mold); product dimensional deviation is within 0.03mm, meeting the requirement of high precision.

FrankaEmika, which has just signed a cooperation agreement with Yizumi this year,will also be on the show, and its co-robot Franka Panda will showcase the pick-up detection solution at the Yizumi booth.

In order to let the participants more fully understand the technical strength of Yizumi, Yizumi will hold a factory open week event at the Shunde headquarters in Guangdong on May 23, and will show more than 15 advanced molding solutions on site. At the same time, we have invited some global industry elites, partners and heavy-weight speakers to exchange ideas for future growth.

For more about the advanced process solutions and products of Yizumi,you are welcome to visit the Yizumi injection molding machine booth 3.1F41.