Yizumi MultiPro-M Horizontal Rotary Table Technology Application

Abstract:

Yizumi MultiPro-M Horizontal Rotary Table Technology Application

Two-color molding has become an important selling point of today's commercial products, from a bottle cap, to the car lights, sunroof, even the bath basin, there are all two-component parts to increase the sense of product design.

Comply with the new product design trend, in recent years, Yizumi has launched MultiPro multi-component molding process, applied to the two-color, three-color parts molding. It has especially excellent performances in the field of automotive industry, introduced by Silver Basis Technology, BYD, ESSENWAY and other customers, used in the production of car light cover, interiors etc.

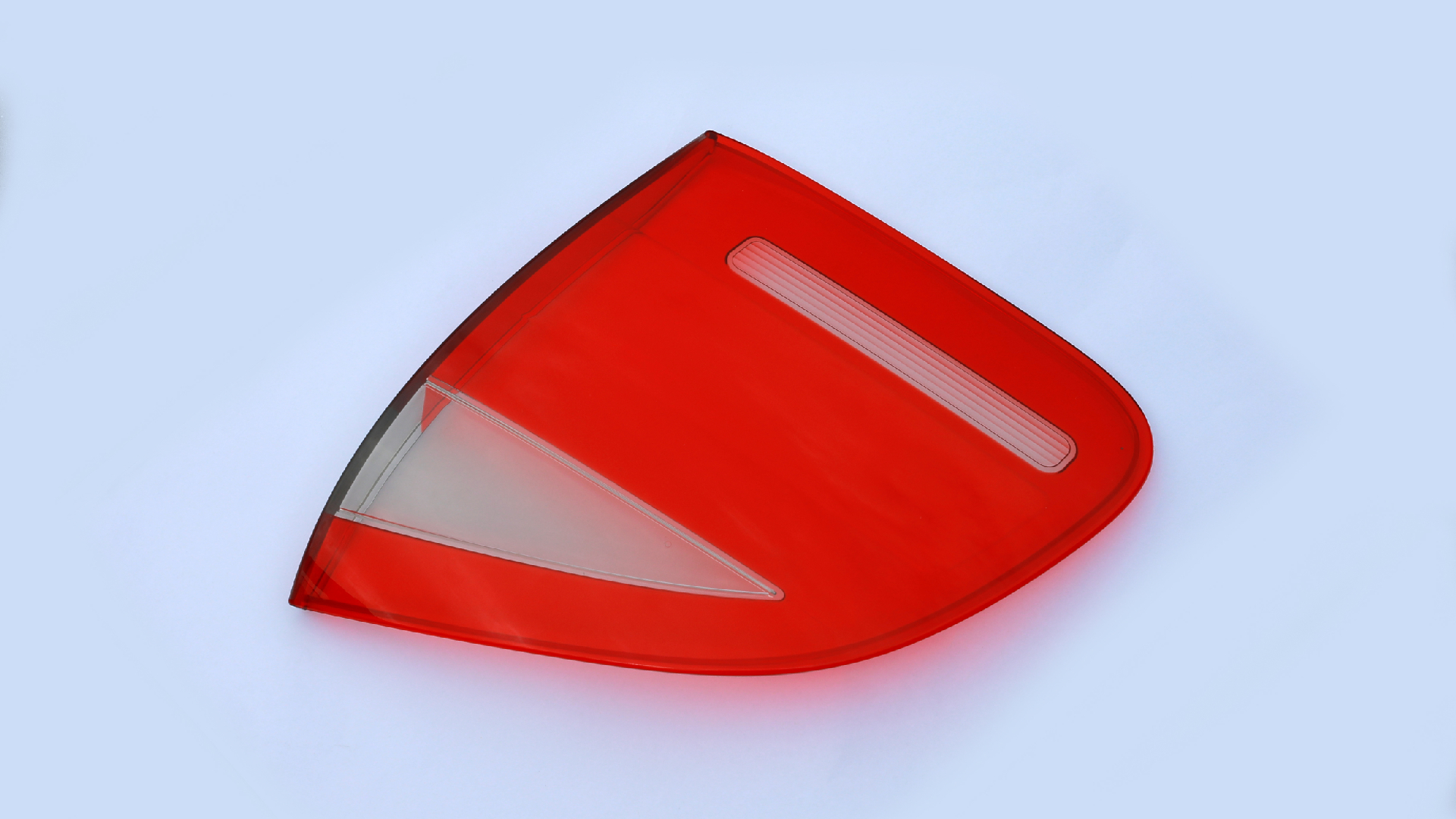

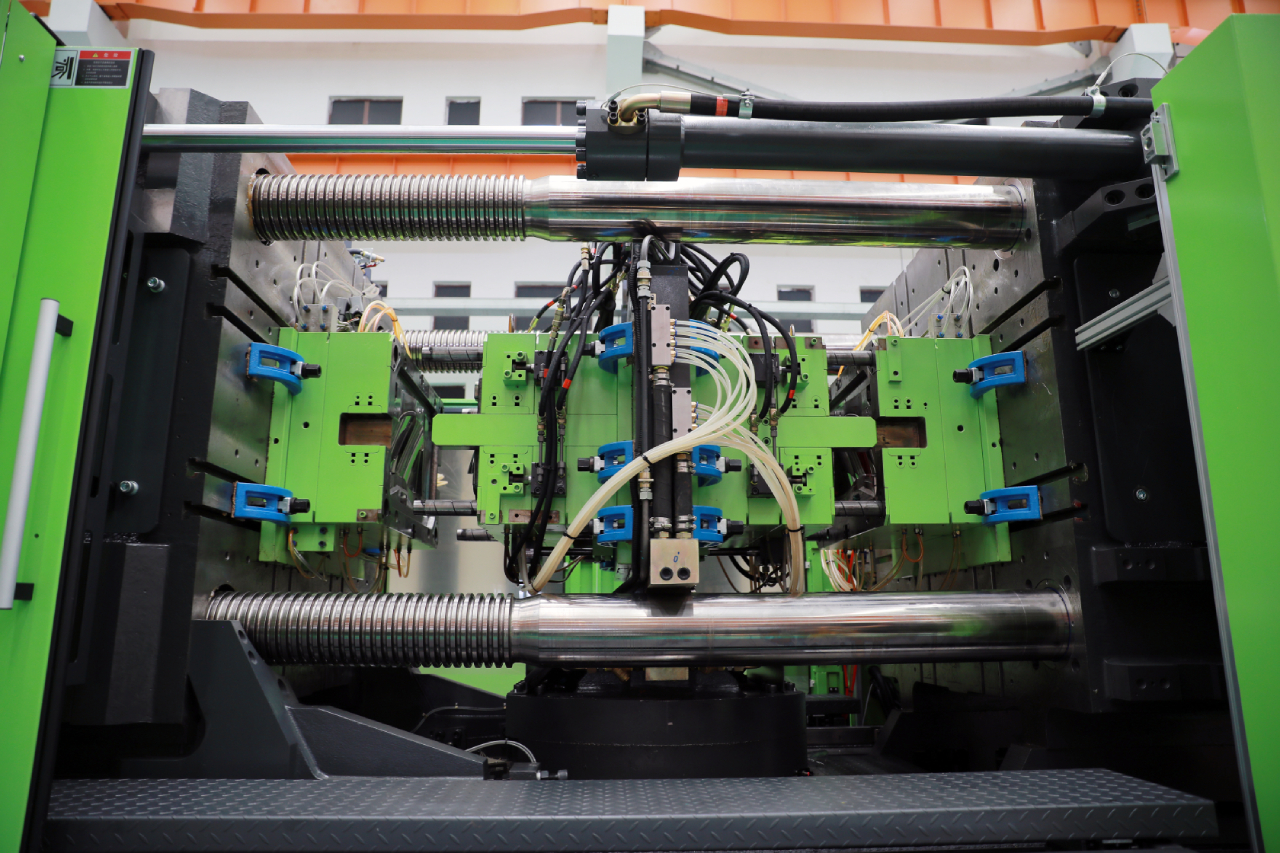

With the gradual development of the vertical turntable, Yizumi launched the Multipro-M Horizontal Rotary Table Technology Application, combined with the platform of its two-platen injection molding machine of 500T-3400T clamping force, and can accommodate the mold of up to 81 tons. The machine is suitable for the production of large two-color parts, such as car sunroof, rain chute, interiors, headlights and taillights cover, etc..

UN900DP MultiPro-M making Porsche taillight cover

Large two-platen machine + horizontal rotary table + correlation structure

Compared with stack mould

▶ Adopting two independently-controlled injection unit, flexible choice of injection volume

▶ High flexibility, capable of using two different molds at the same time

▶ Reduce the length of the hot runner, lower cost

▶ Improve hot runner balance, make commissioning and starting-up faster

▶ Reduce the residence time of raw materials in the barrel

▶ Less raw material degradation and better quality control

Compared with vertical turntable

▶ Same tonnage machine, the number of cavities is doubled and the output is doubled

▶ With the same output, the machine tonnage can be reduced by nearly double, the energy consumption is lower, and the cost of equipment and mold is lower

▶ Standard moving platen and middle platen mold-open synchronous core pulling, secondary shooting table and moving platen move synchronously, fast turntable positioning, shorter cycle time.

▶ The arrangement of the secondary shooting table is not restricted by space, and can meet the requirements of special application processes, such as physical foaming, chemical foaming, PU foaming, and other coating processes.

Manufacturing better large two-color auto parts

▶ Automotive: sunroof, rain chute, car light cover, interiors and other large two-color products;

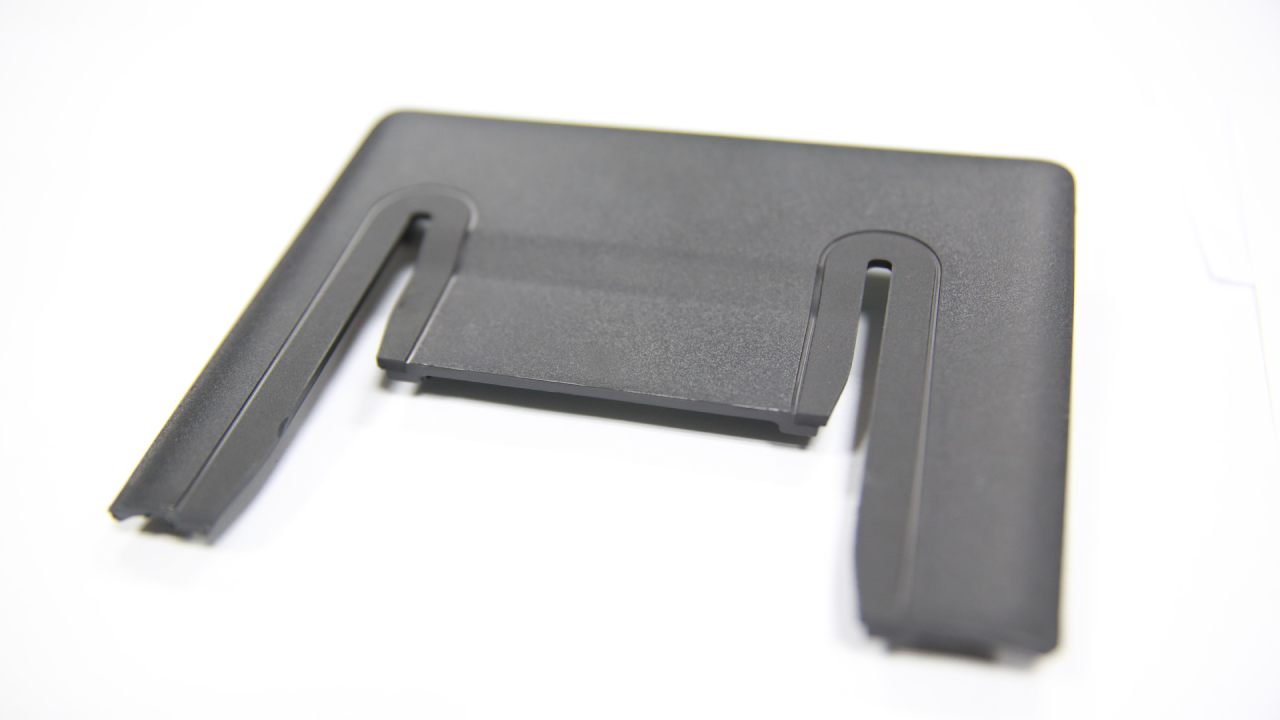

▶ Home appliance: TV frame, air conditioning panel, etc

▶ Consumer electronics: laptop housing, speaker housing, power tools, etc

▶ Daily necessities: baskets, two-color basins etc.

>>>Slide for more pictures>>>