Yizumi Gets New Expertise: Turntable for 2K Injection Molding

Abstract:

Yizumi Gets New Expertise: Turntable for 2K Injection Molding

This year, Yizumi two-platen injection molding machines become more versatile: they are capable of producing McLaren and Lamborghini two-color car lights with double injection units and a 2K turntable which was jointly developed by ASM and Yizumi.

Commissioning of Lamborghini rear lamp mold

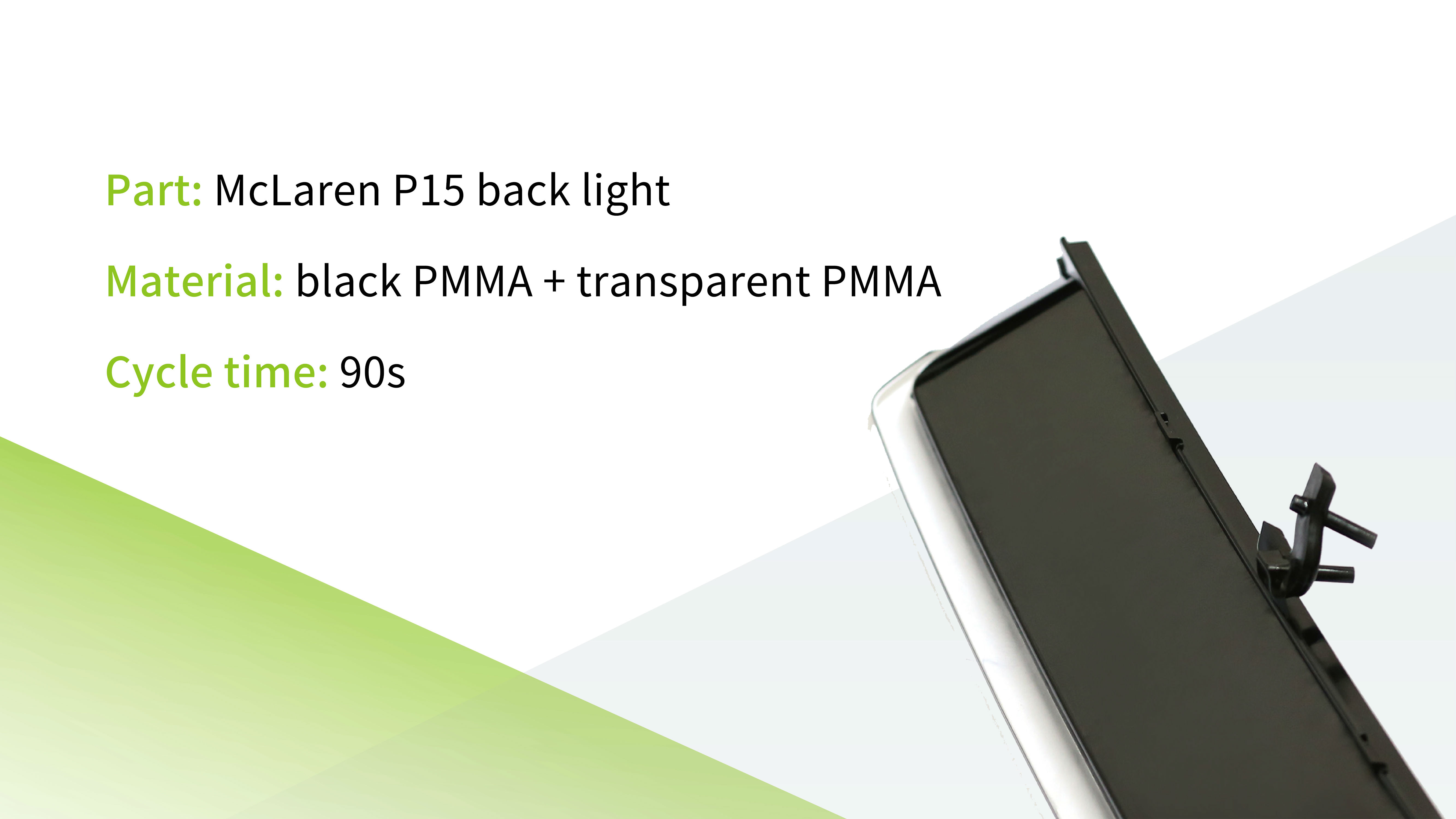

ASM has been focused on developing two-color car lights and engine-related products in recent years. This year, ASM obtained an order for three 2K molds from Wipac—a world-leading automotive lighting manufacturer—and the molds would be used in the production of McLaren and Lamborghini limit-edition rear lamps. Since then, ASM and Yizumi started cooperation in R&D.

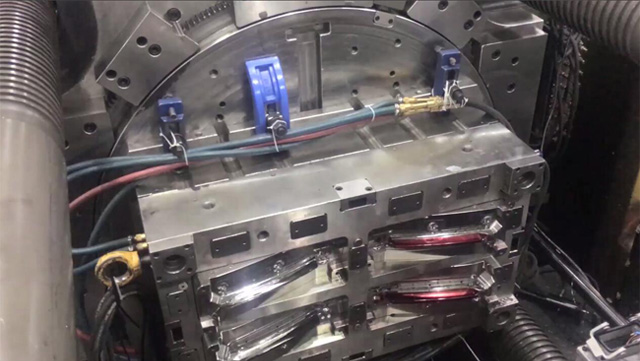

In July 2017, Yizumi accomplished the development and manufacture of the 2K turntable. Then ASM installed it on a Yizumi UN1200D1 two-platen injection molding machine which had two injection units to complete commissioning of three molds. The results showed that the cycle time of producing McLaren rear lamps made from black and transparent PMMA was 90 sec and the maximum thickness of molded parts was 8mm.

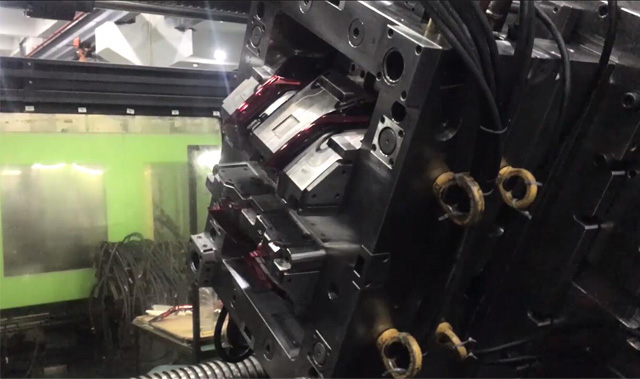

Commissioning of Lamborghini rear lamp mold

The successful development and application of 2K turntable means that Yizumi can provide large two-platen injection molding machines integrated with 2K turntables or just separate 2K turntables. The molder can achieve two-shot or multi-shot injection molding with the coordination of a 2K turntable, one or multiple sets of auxiliary injection unit and a mold, which is more competitive than a traditional 2K injection molding machine in the machine weight, cycle time and footprint. The new solution also reduces the costs of mold design, manufacturing and assembly and dispenses with second mold opening and closing during mold transition, which improves production efficiency.

Yizumi 2K turntable

Last year, Yizumi successfully developed the auxiliary micro injection unit. With the application of 2K turntable, Yizumi has provided 2K injection molding solutions for many auto suppliers, for example, Silver Basis. The manufacturer purchased a custom Yizumi UN1100D1 2K turntable system which worked with its self-developed flow distribution system to enable the turntable to rotate 360 degrees. The system integration greatly met the needs of multi-station multi-shot injection molding.

With regard to the future development of 2K technology applied to two-platen presses, Yizumi Two-platen IMM Project Manager Hou Yongping said that Yizumi would persist with indigenous innovation and continue creating cost-effective large two-platen press and 2K turntable integration solutions that live up to European technical standards for customers.