Yizumi All Electric Injection Molding Machine Facilitates the Upgrade of Building Blocks Industry

Abstract:

Yizumi All Electric Injection Molding Machine Facilitates the Upgrade of Building Blocks Industry

When it comes to toy blocks, we think of Lego. Lego is undoubtedly synonymous with building blocks. With its ultimate product quality and continuous innovation, it has become the most successful enterprise in toy building block industry. However, the high price of Lego blocks holds many Chinese families back. An insider admitted that the current monthly income of Chinese families is less than RMB40,000, and it is difficult for them to buy and play Lego blocks with ease.

Compared with Lego’s strong premium ability, China’s toy building bricks industry is constantly exploring the most cost-effective and more “Lego-like” business model. Nowadays, a number of high-quality brands have emerged in China. They pursue original design and let children enter a wider and diverse building block world through the operation mode of “building blocks + IP (such as Peppa Pig and COGOMAN)”. In production management, they pursue high-quality and high-efficiency production, pay attention to details, strictly control the precision of mold and improve the grade of materials. In addition, all electric injection molding machines become increasingly popular among those toy building brick manufacturers, replacing traditional hydraulic machines and producing toy building bricks that can rival Lego in terms of the gloss of appearance or the feel of the splicing. The production with electric injection molding machines is much more efficient and environmentally-friendly.

All electric injection molding machines accelerate the transformation and upgrading of China’s building block toy industry. Compared with hydraulic injection molding machines, all-electric injection molding machines are energy-saving, environmentally-friendly, low-noise and accurate in measurement. They can better cater to the environment requirements of toy building block manufacturing and pave the way to the establishment of smart factories. They are an ideal choice for toy building block manufacturers. To meet specific injection molding requirements of toy building blocks, Yizumi continuously optimizes the FE series all-electric injection molding machines. So far, they are stably operating in many well-known toy factories such as QMAN, Qun Long, HUADA, Lezhi, etc. without injection molding defects like air holes and weld lines, improving production efficiency by 30% to 50% and facilitating the transformation and upgrade of China’s building block industry.

● Wide process window with high efficiency

The injection system of the FF series machine is equipped with a front-mounted pressure sensor. The injection pressure and plasticizing back pressure are directly applied to the sensor from the screw, which makes the control more precise and stable. The temperature is controlled by PID with accuracy up to ±0.5℃. The resin is well melted. The final products are excellent flawless with durable color and gloss.

● Stable operation ensures high precision of products and protects the molds

The flexible clamping unit design (parallelism is 0.03mm) ensures that mold opening and mold closing are smooth. Zero contact between tie bars and the movable platen can reduce the friction during the mold closing process, thereby improving the speed and smoothness of mold movements, which is very beneficial for the production of precision products. The unique two-platen clamping mechanism can eliminate the nonparallelism of mold, avoid flashes and protect the mold. Yizumi all electric injection molding machines are ideal for companies that have the needs of mass production and maintenance of high-precision and high-cost molds.

|

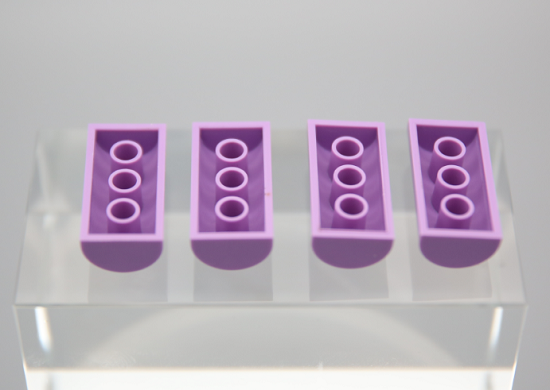

Application example:Semi-cylindrical building blocks Model of IMM: FE180-910s Part weight: 1.9g Material: ABS Size: 31.8 mm×15.8 mm×9.7 mm Wall thickness: 1.5mm Cavity: 1×48 Gate weight: 53g Cycle time: 15s |

|

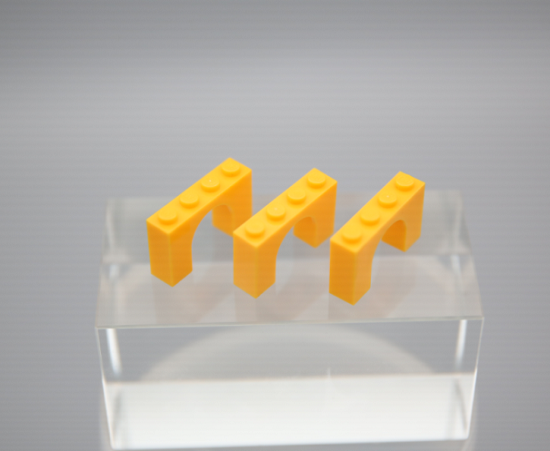

Application example: High-arch building blocks Model of IMM: FE260—1400s Part weight: 2g Material: ABS Size: 32 mm×7.82 mm×21.2 mm Wall thickness: 1.5mm Cavity: 1×96 Gate weight: 145g Cycle time: 16.6s |

|

Application example: Seven-hole building blocks Model of IMM: FE180—910s Part weight: 1.7g Material: ABS Size: 55.4mm×7.5 mm×7.85mm Wall thickness: 1.4mm Cavity: 1×32 Gate weight: 49g Cycle time: 15.88s |

Note: The above machine data are according to in-house test and inspection standards.