W1 Series——Tailor-made for the Deep-cavity Products

Abstract:

W1 Series——Tailor-made for the Deep-cavity Products

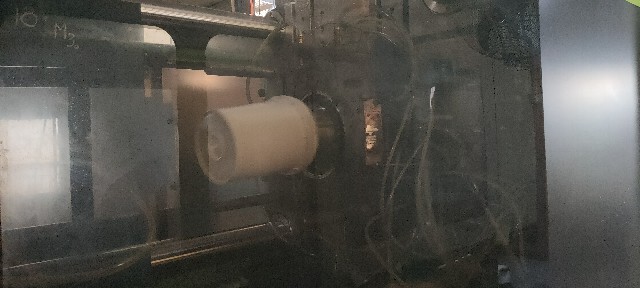

The well-known Malaysia plastic pail manufacturer——TACOPLAST INDUSTRIES SDN. BHD. recently introduced a unit of YIZUMI W1 Series special machine UN680W1, which has been successfully put into the production of 18-liter deep-cavity plastic pails.

Founded in 2021, TACOPLAST mainly engages in the manufacture of high-quality paint pail and other products for the paint and food industry, which covers the Southeast Asian and Indian markets.

Facing fierce market competition, TACOPLAST has been seeking more efficient and automated production solutions and reliable equipment with high speed, higher precision, and stability.

YIZUMI W1 series machine is specifically designed for deep-cavity products. It applied a new kind of clamping structure ——an outward toggle, which will turn to the outside during mold opening. Compared with the inward toggle machine, the W1 series machine can directly transmit the clamping force to the mold and therefore minimize the mold deformation. Besides, the opening stroke and the machine application range can be larger, not limited to the in-mold space, especially suitable for the production of deep-cavity products such as trash bins, barrels, chemical buckets, plastic stools, and the outer drums of washing machines.

▲ The stress centralized on the two platens, which minimizes the platen deformation, improves the effective clamping force, and reduces the flash;

▲ The large opening stroke supports the wide application range of the machine;

▲ Stable mold opening and closing, fast speed, short cycle time, efficiency improvement;

▲ Improve the utilization rate of clamping force, save energy and reduce the wear and tear of the machine.

YIZUMI self-developed W1 series machine for deep-cavity product production is available with clamping forces from 530T to 1100T. Its structural parts including clamping structure with extra-long mold opening stroke, platen with high rigidity and small bending moment, and split-type ejection mechanism with low inertia, have obtained intellectual property protection. The standard machine equipment includes clamping structure with long mold opening stroke, servo pump, proportional valve for mold opening and closing, safety valve, safety module, KEBA control system, etc., which also can be adopted in in-mold labeling as well as robot removing as required, further providing higher cost performance.

The head of the TACOPLAST said: “The clamping structure with long opening stroke and the electric storage of YIZUMI UN680W1 can achieve shorter cycle time. The current cycle time stabilizes in 23 s, 20% shorter than the original cycle time. We believe that the cycle time can at least reduce to 18 seconds if using a new mold, and the production efficiency will be significantly increased.”

“We expect to keep close cooperation with YIZUMI and WY MACHINERY. As our agency company, WY MACHINERY’s after-sales service team can solve our problems in time with excellent attitude and standard. We also hope YIZUMI continues to provide us a better price and higher cost-effective solutions.”