【Video】New Direction for Biodegradable Injection Molding

Abstract:

【Video】New Direction for Biodegradable Injection Molding

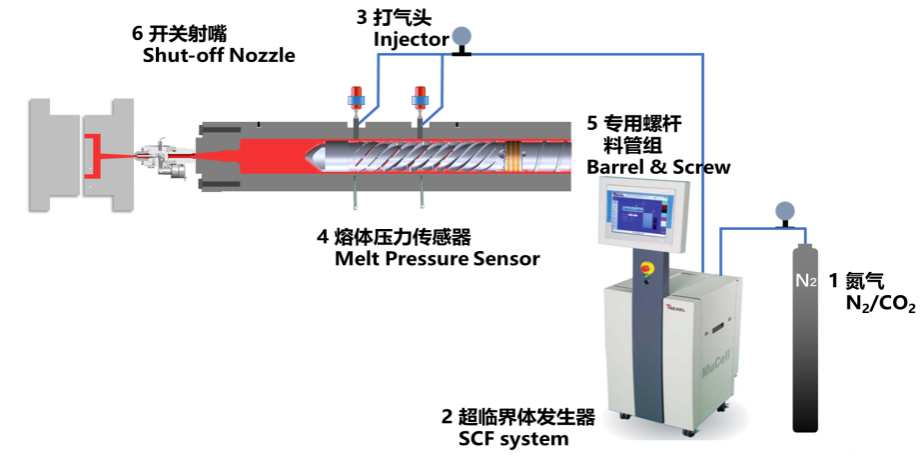

FoamPro Packaging Microcellular Foaming Injection Molding Solution

The packaging manufacturers have been asking for new technological breakthroughs to optimize product design and texture. Mucell microcellular foaming technology can give them a hand and provide a brand-new solution.During the Mucell foaming process, supercritical fluid (nitrogen or carbon dioxide) is injected into the polymer melt. After being injected into the cavity, the polymer melt starts to form bubbles and expand. When the filling completes, the foaming stops because of melt cooling and limited swelling capacity. A microcellular structure is ultimately formed in the product.It is characterized by reducing the product weight, cycle time, warping, and clamping force, providing unique advantages over conventional injection molding.

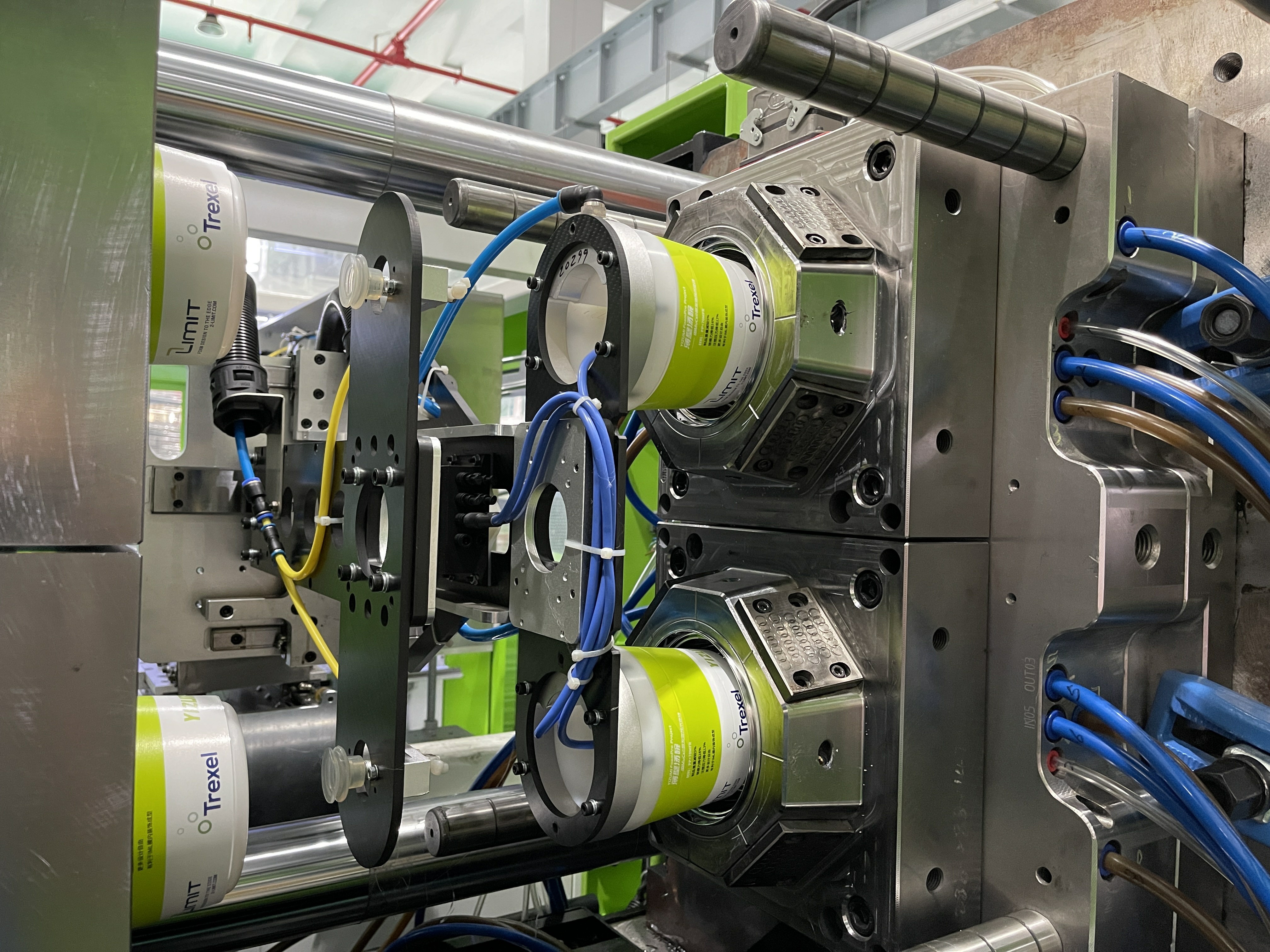

Based on the in-depth development of MuCell technology, YIZUMI’s FoamPro microcellular foaming solution has been applied in the fields of automobiles and home appliances. At CHINAPLAS 2021, the YIZUMI FoamPro solution was equipped with PAC250K high-speed injection molding machine, Mucell equipment, an in-mold labeling system, and a two-cavity hot runner mold, displaying more high-quality and environmentally-friendly packaging production with more design freedom.

In this application example, FoamPro microcellular foaming solution improves the melt fluidity and eases the molding, especially the molding of full biodegradable plastic. Nowadays, the demand for the fully biodegradable PLA is growing in the packaging industry. However, there are some application problems because of its melt index (3-5MFR), poor fluidity, difficult molding. The Mucell technology will contribute to better fluidity and easier part molding with the mixture of the supercritical gas and plastic melt.

FoamPro can also provide flexible design of wall thickness, improve part size stability and reduce warpage.

Meanwhile, the lightweight feature of Mucell technology is reflected: reduction in part weight by 5%, injection pressure by 15%, and clamping force by 20%. More cost-saving and environmentally friendly compared with traditional packaging part.

Moreover, Mucell technology also upgrades the part uality, namely microcellular foaming packaging is thicker, stronger, and more heat-insulated (20%-30% up) than regular injection molding packaging part at the same weight.

Overall, FoamPro microcellular foaming packaging injection molding solution has unique advantages in part molding, design freedom, warpage reduction, energy-saving, quality, etc. It is especially suitable for packaging production requiring high quality and flexible design.

Product: Microcellular Foaming Container.

Number of cavities: 2

Capacity: 1LPart

weight: 25.6g

Cycle time: 6.5s

Partners: Trexel, 2Limit, SWITEK, Sabic, Bowei

※The Data above were acquired by testing in the factory, only for your reference. The specific data please refer to the actual equipment.