Online Open Week|How IMDPro In-mold Decoration Achieve Higher Yield?

Abstract:

Online Open Week|How IMDPro In-mold Decoration Achieve Higher Yield?

Recent years, smart surface and surface with strong visual impact are more and more popular which makes IMD in-mold decoration technology even hotter.

IMD refers to a foil painted with special design is placed inside the mold. After filling with plastic, the foil adheres to the plastic parts, therefore, products with decorative and functional surface can be produced. So far, IMD technology is widely used in automobile, home appliances, consumer electronics, medical electronics and other industries.

Compared with traditional processes, IMD technology enables to produce product with various colors and pattern designs in one step. Besides, it is convenient and easy to change the colors, the cost of mass production is low as well. However, how to achieve higher yield rate and reduce the expensive foil cost even in low production has become an urgent problem for manufacturers.

YIZUMI IMDPro in-mold decoration molding solution is allocated with FF series electric injection molding machine. Combined with secondary clamping technology, it could achieve higher yield rate and efficiency. Besides, the solution is equipped with automatic equipment in order to satisfy full automatic manufacturing requirements.

YIZUMI FF series electric injection molding machine features with high injection speed and injection pressure, stability as well as precision, which commendably meets the IMD manufacturing equipment demand of no shrinkage and no flash. In addition, the machine enables to reduce grease and dust pollution that ensures the working environment clean and environment-friendly. Therefore, the yield rate of product can be greatly improved. Meanwhile, it is beneficial to provide intelligent operation and integrated solution.

Value Advantages:

·Stable and precise: the product weight repeatability reaches 0.3%;

·High injection speed and injection pressure: injection speed has improved by 2-3 times, plasticizing speed has improved by 2 times, mold open and mold close speed have increased by 30%. Synchronized ejector movement and plasticizing can be realized;

·Clean and environment-friendly: Non-contact tie bars and ball screw driving reduce grease pollution and leakage;

·Smart injection: SIC Smart Injection Control solves the uneven filling problem of multi-cavity molds; SPH Smart Clamping Force Retention System automatically remains clamping force during operation.

※The Data above were acquired by testing in the factory, only for your reference. The specific data please accord to the actual equipment.

YIZUMI Online Open Week will be held on 14th September in Wujiang Factory. At that time, IMDPro solution will showcase the IMD automatic production line including FF160 electric injection molding machine, foil feeder, removal robot, engraving and milling machine, producing product from raw material to product in only one step.

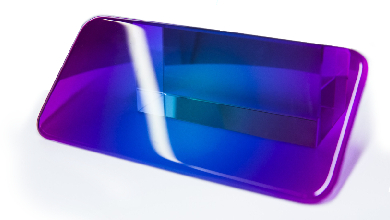

5G Mobile Phone Back frame

If you want to take part in the Open Week, watch the solutions on site, please contact with the YIZUMI sales managers in your area.