Mask production on YIZUMI new version electrical injection molding machine in Germany

Abstract:

Mask production on YIZUMI new version electrical injection molding machine in Germany

The latest success story comes from the Bavaria, Germany! Face masks are manufactured by WeForm Werkzeug and Formenbau GmbH.

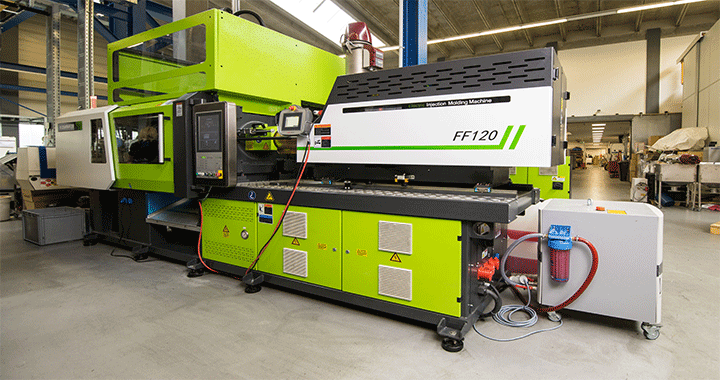

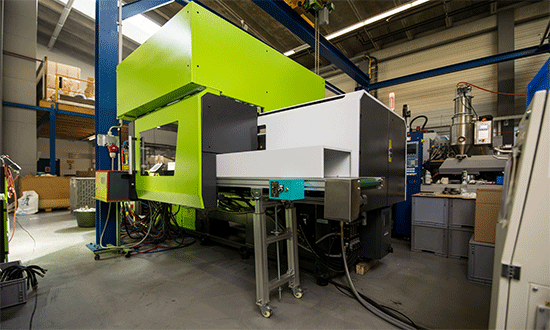

The production is carried out on a YIZUMI FF120 electrical injection molding machine with the Face masks. Due to the high precision of the machine, the FF120 has a wide range of applications in the field of medical technology. At the same time, the FF120 is not only to produce the Face masks, thanks to its multi-functionality, the pipette sleeves are also made on FF120 by a 24-cavities mold.

More precision, more energy efficient, faster, better automated - and still affordable.

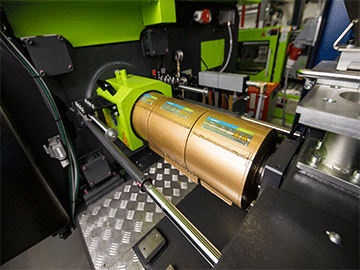

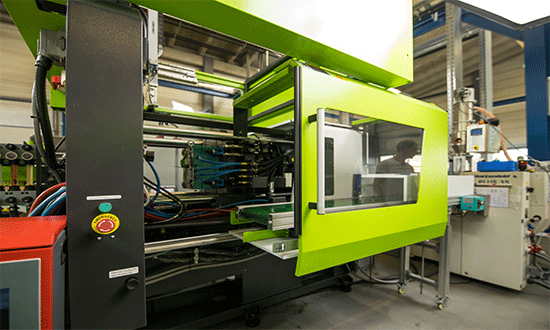

These benefits come together in the face mask production on the FF120. The injection process can be controlled with higher precision servo motor to achieve better accuracy on the injection volume, which is reflected in the quality of the components in the Medical production.

The injection speed of 200mm/s also corresponds to the latest standards. Including this feature, the FF120 is the perfect choice for thin-wall production of pipettes for example.The electrical clamping unit also moves precisely to the point and thus guarantees a clean component transfer to the handling device.

Thanks to the servo-electric drives of the injection units and clamping units, the parallel movement of plasticising during the mold closing is the standard feature. In most cases, this can support to significantly reduce the production cycle and increases production efficiency significantly.

The servo motor drives are currently the most energy-efficient drive concept on the market. In combination with the infrared plasticizing heater, it results in an extremely energy-efficient overall machine concept.

Since injection molding machines with hydraulic core pullers are very often in demand on the German market, the FF series from YIZUMI has a small hydraulic circuit and core puller as standard. In order to keep the machine attractive from the investment costs, this hydraulic system also controls the nozzle system and the ejector.

Automation concept:

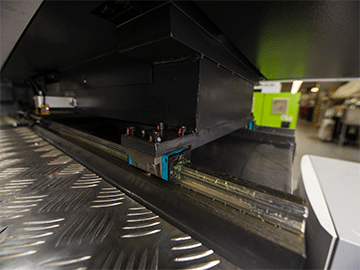

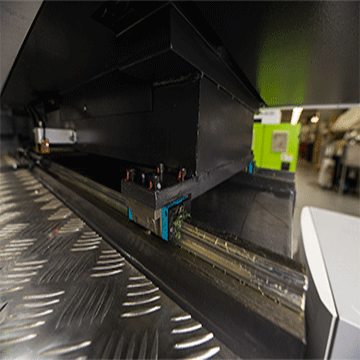

A linear robot is installed on the FF120. The handling device places the parts within the widened protective housing.

The mask:

The reusable mask is washable and of course suitable for dishwashers. Any filter inserts can be clamped from the inside. Replacing the inserts could be easier. The soft TPE and three-dimensional contour ensure a high level of comfort.

About Yizumi:

Yizumi Precision Machinery (Germany) GmbH was founded in January 2020 as a direct sales and service company for the Chinese machine manufacturer in Germany. Yizumi Precision Machinery (Germany) is responsible for the sales and service of injection molding machines in Germany. The main headquarters are in Stein near Nuremberg. Robert Weber is responsible for Southern Germany, Austria and Switzerland, Ümüt Topbac is the contact person for customers in Northern Germany, Benelux and Scandinavia. Both learned from Krauss Maffei and Milacron and have been successfully working for the Yizumi for two years.

Yizumi Precision Machinery (Germany) GmbH.

Address:Gewerbering 8 90547 Stein

Tel.:+4991168938328

Fax.: +4991168938327

Director Sales & Service

Ümüt Topbac

Mobile: +49 15780514644

Mail: ue.topbac@yizumi.com

Robert Weber

Mobile: +49 15780514645

Mail: r.weber@yizumi.com

Cooperation partner:

WeForm

WeForm is Yizum’s cooperation partner and a specialist in the design and manufacture of plastics technology injection molds. From part development to the finished product.You get those in good quality with consistent precision.

WeForm was founded in 2002.It produces precision machine components as well as devices and machines according to customer requirements. In addition, the company produces plastic parts for many business area in the injection molding shop. The regular customers are well-known companies from a wide variety of industries: from the toy parts to industry and automotive applications.

KRAIBURG TPE

In addition to production, the suitable raw materialand the corresponding additives are important for the end product. Thehigh-quality granules from KRAIBURGTPE are used for the mask. "It isimportant for us to support our customers in partnership with their projects.Especially when it comes to protecting health," says Michael Pollmann, Sales& Marketing Director EMEA at KRAIBURG TPE, and adds: "The materialused TPE is ideal for the production of masks, TF5CGN is food-safe, has a softsurface and is easy to clean, so it is also used in sensitive areas, such ashygiene products, but also in toys and food packaging. Of course, our materialalso has the appropriate standards and license. "

Color Service GmbH & Co.KG

The Color Service GmbH & Co.KG supported us with advice and material to help us make the right additive selection. For example, special colours (master batch) were mixed in the laboratory and now tested for mask production.

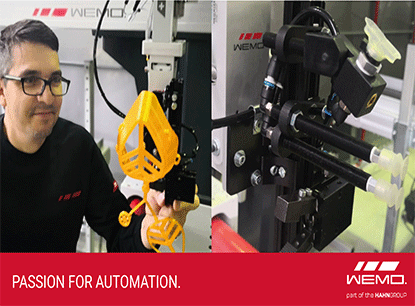

The WEMO AUTOMATION GROUP

The WEMO AUTOMATION GROUP is one of the leading international manufacturers of linear robot systems and automation cells for the plastics industry and part of the HAHN Group. Company Wemo is now a global supplier with a customer base of more than 10,000 installed robot cells worldwide. WEMO offers over 30 years of experience with linear robots.

Spread over branches in Sweden, Germany and India WEMO has innovative solutions with greater usability, efficiency and performance of automation, as well as a long service life. Individual turnkey solutions includes linear robots, conveyor belts, protective fences. Linear axis and gripper systems are offered as well as packaging automation and automation with articulated arm robots.