Industrial Internet Arrives in the Right Time as the Capacity Multiplier

Abstract:

Industrial Internet Arrives in the Right Time as the Capacity Multiplier

At present, the manufacturing industry is experiencing more and more fierce competition, coupled with the uncertainty of the external environment. Under the pressure of reduced foreign trade, enterprises urgently need to break through by allowing the existing assets to play a greater role to improve efficiency and generate higher earnings.

In this regard, the use of technical means such as the Industrial Internet, digitization, informationization, and Industrial 4.0 as the new foothold for expanding the capacity of the enterprises has become the novel trend of the industry. However, promoting the construction of informationization using traditional architecture will face many obstacles including high investment costs, poor network facilities, weak technical team, difficult to upgrade operations and maintenance, these factors hinder the transformation and upgrade of the enterprises.

The Industrial Internet platform launched by Yizumi in 2018 has effectively solved the above pain points by adopting the new generation of ICT technologies such as cloud computing, big data, and IoT, providing customers with professional and cost-effective digital solutions. With a focus on the production management in the injection molding industry, the platform helps customers to solve problems in production processing related to production monitoring, efficiency statistics, fault handling, and process analysis and improve their productivity and product quality. It has now been used by nearly 100 customers, serving thousands of devices.

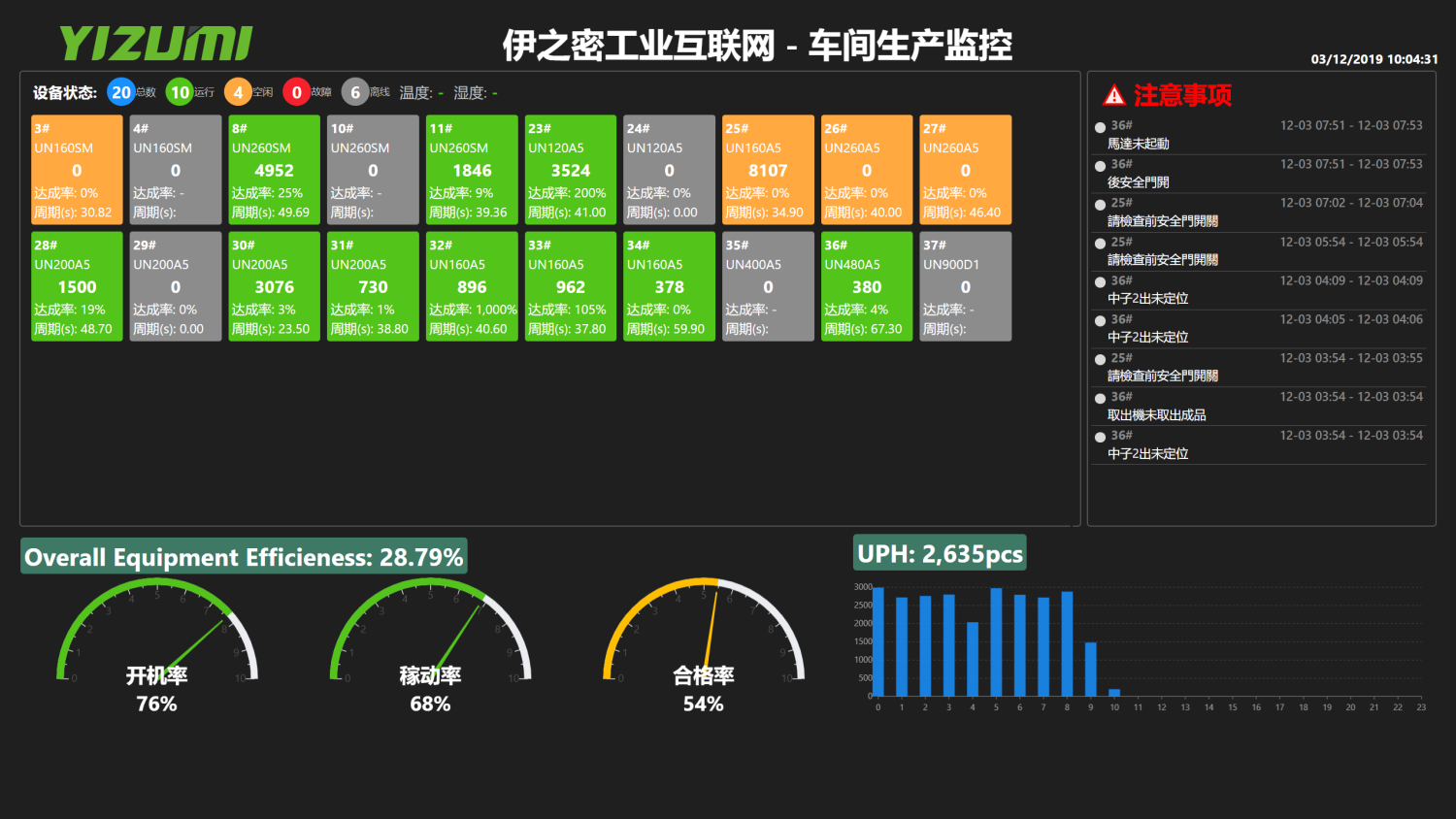

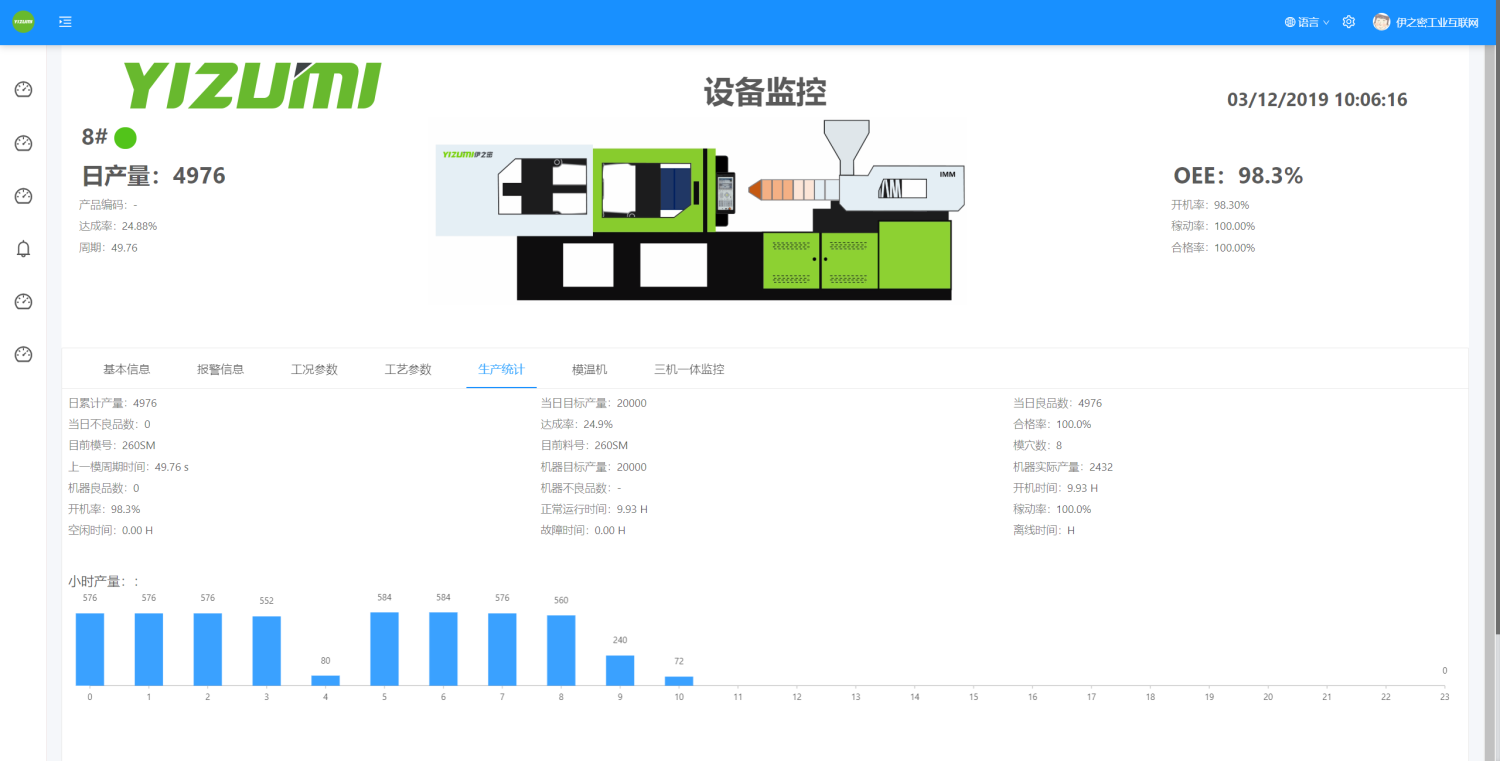

CMS (Condition Monitor System) is one of the most basic functions in the architecture of Yizumi’s Industrial Internet platform. When devices are connected to the network, users are able to monitor the devices anywhere and anytime via mobile app or PC, to view machine utilization ratio, uptime, product qualification ratio, production cycle, yield, and other data in addition to information used in statistical analysis of equipment overall efficiency and output. In case of equipment failure, users will also receive text message or WeChat prompt in a timely manner.

For enterprises, the greatest value of monitoring lies in the digitization and visualization of production.

“Our analysis reveals that the comprehensive utilization ratio of an enterprise’s production equipment rarely exceeds 60%. However, many employers may not be aware of these data, or even make additional investment in equipment blindly. The CMS can help them solve the digitiization issues.” said Niu Jianwen, Director of Intelligent Connection Department of Yizumi.

Take 100 machines as an example, if the utilization ratio increases from 60% to 70%, it means an increase in the production capacity of 10 machines, giving full play to the efficiency of the existing machines. Under the same conditions of fixed assets and energy consumption, corporate earnings will be significantly improved.

Digitization can help the managers to collect production data for decision making while visualization can help to find and solve problems in a timely manner.

“For a workshop with 100 machines, it takes a manager 2 hours to complete one round of inspection. But the manager cannot spend the time at the scene every day. CMS can make the operating status at workshop visible, allowing the manager to coordinate resources and resume production quickly.”

More specifically, users only need to add IOT hardware in order to implement the system with features on-demand. There is no requirement for additional investment in fixed assets which greatly reduces the technical threshold as well as building and operation costs for customers to achieve intelligent production.

“CMS is a standardized information management system that can fit various industrial application scenarios. We want to provide our customers with the best cost-effective solutions.”

A capacity multiplier should not only help the machines to “run” better, but also helps PO management, cost control, and quality improvement.

“The core of an enterprise is QDCP”, said Niu Jianwen. QDCP stands for quality, delivery, cost, and productivity. In order to achieve that, you need to establish a MES system to optimize production order management, production operation management, quality management, data collection and analysis, as wells as process management.

Yizumi has started to provide customers with customized MES system since 2019. “Different enterprises have different needs for MES. Even if they are in the same industry, they have different focuses which lead to different MES functionality.”

For example, the characteristics of high-volume production determine that customers in 3C industry weigh productivity management heavily. Small household appliance industry attaches great importance to mold management because of the diversity of their products, while customers in the automotive industry pay more attention to the quality management and traceability..

Designed specially for injection molding and aluminum die-casting industries, Yizumi’s MES system adopts new technologies such as cloud computing and IoT to provide customers with the best cost-effective solutions.

In the future, Yizumi’s Industrial Internet platform will further extend its capacity around the customer’s production management scenario and provide more SaaS (Software-as-a-Service) services, including intelligent service (e-Service), quality management service (QMS), energy management service (EMS), mold management service (MMS), prognostics & health management (PHM), smart financial leasing (SFL) in addition to CMS and MES software. “Customers can simply choose the software services on the platform according to their needs without making a large sum of investment to establish the information system.”

Diversified softwareservices can further enhance the digital and intelligent level of customers’production management, and thus make production management more scientific,efficient and simple. When there are many factories gathering on this platformand forming an ecological community, capacity sharing, information sharing, andcollaborative manufacturing within the industry become possible.

In the future, Yizumi’s Industrial Internet platform will further extend its capacity around the customer’s production management scenario and provide more SaaS (Software-as-a-Service) services, including intelligent service (e-Service), quality management service (QMS), energy management service (EMS), mold management service (MMS), prognostics & health management (PHM), smart financial leasing (SFL) in addition to CMS and MES software. “Customers can simply choose the software services on the platform according to their needs without making a large sum of investment to establish the information system.”