High-speed Molding, 460,000 Pipette Tips per Day

Abstract:

High-speed Molding, 460,000 Pipette Tips per Day

Pipette tips, as an indispensible laboratory tool in scientific research and experiments, are widely used in such areas as clinical diagnosis, bio-technology, pharmaceutical research, chemical experiments, food examination and etc. People are most concerned about the quality of pipette tips because it determines how accurate and precise an experiment can be. So for the manufacturers what’s most important is to ensure that their products are sanitary and deformation-free.

Requirements: clean and deformation-free

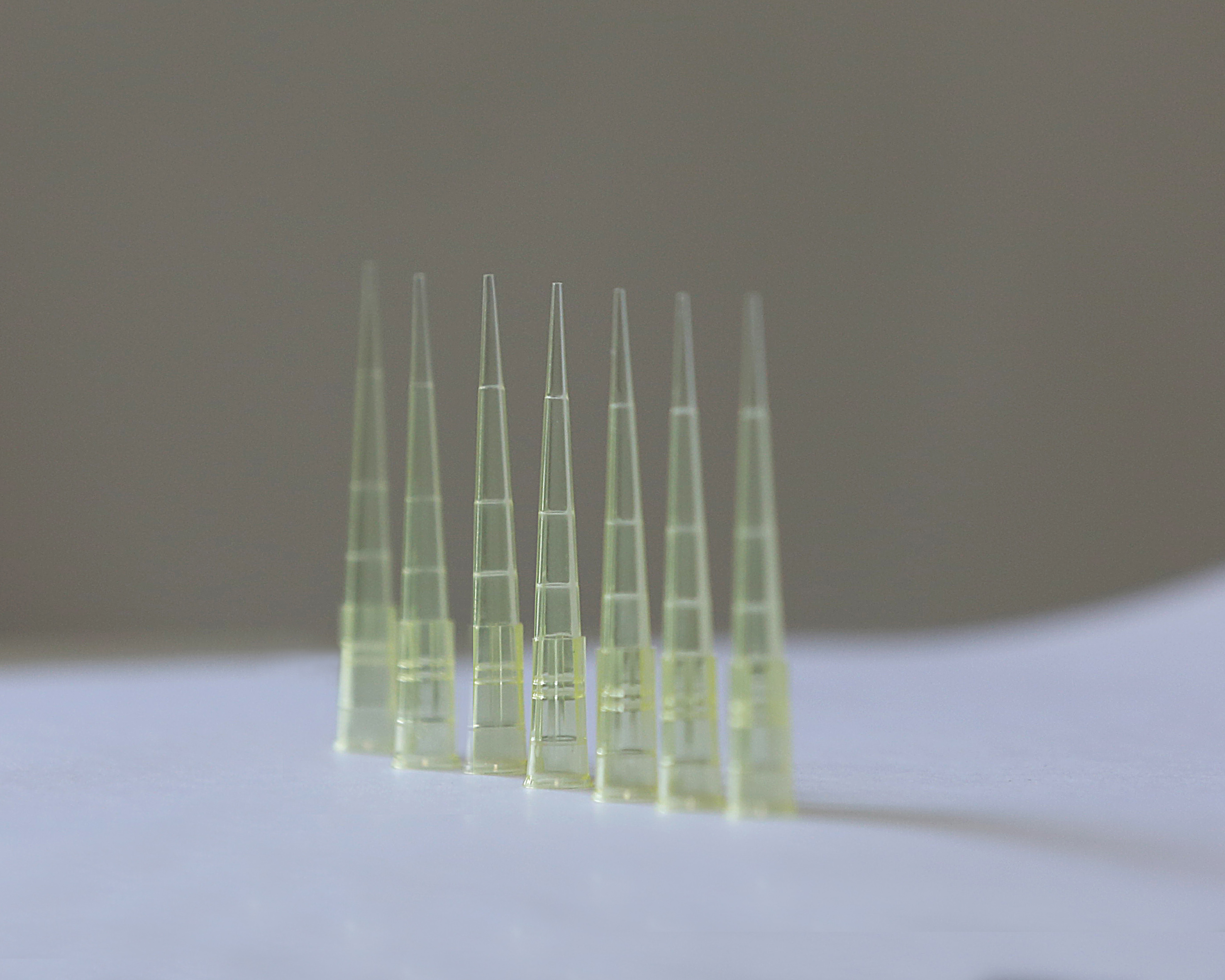

To meet the demand of European customers, a medical plastics manufacturer in Zhongshan, Guangdong Province, needs to produce a batch of high-quality pipette tips with a length of 50 mm, a wall thickness of 0.4mm and a mouth diameter of 0.05mm. To meet the hygienic standard for production, the company creates a super clean manufacturing environment with strict quality control to make sure there is no DNA polymerase, RNA polymerase or pyrogen in the workshop.

Like the other pipette tip manufacturers, the company attaches much importance to the quality of their products. As one-off products for specific applications, Pipette tips, with a large market demand, are required to be straight, stable and deformation-free. And a 100 product percent of pass rate is needed.

If the hydraulic injection molding machine were used, there might be oil pollution in production, or high pressure in the mold due to lower injection velocity of the hydraulic machine, thus deforming the products. Meanwhile, the product would be fragile under high temperature. A technical manager of the company said, “We once tried the hydraulic high-speed machine, but these problems remained inevitable. And the high-speed all-electric injection molding machine has proved to be a good solution.”

All requirements met: 460,000 pipette tips per day, 100% up to standard

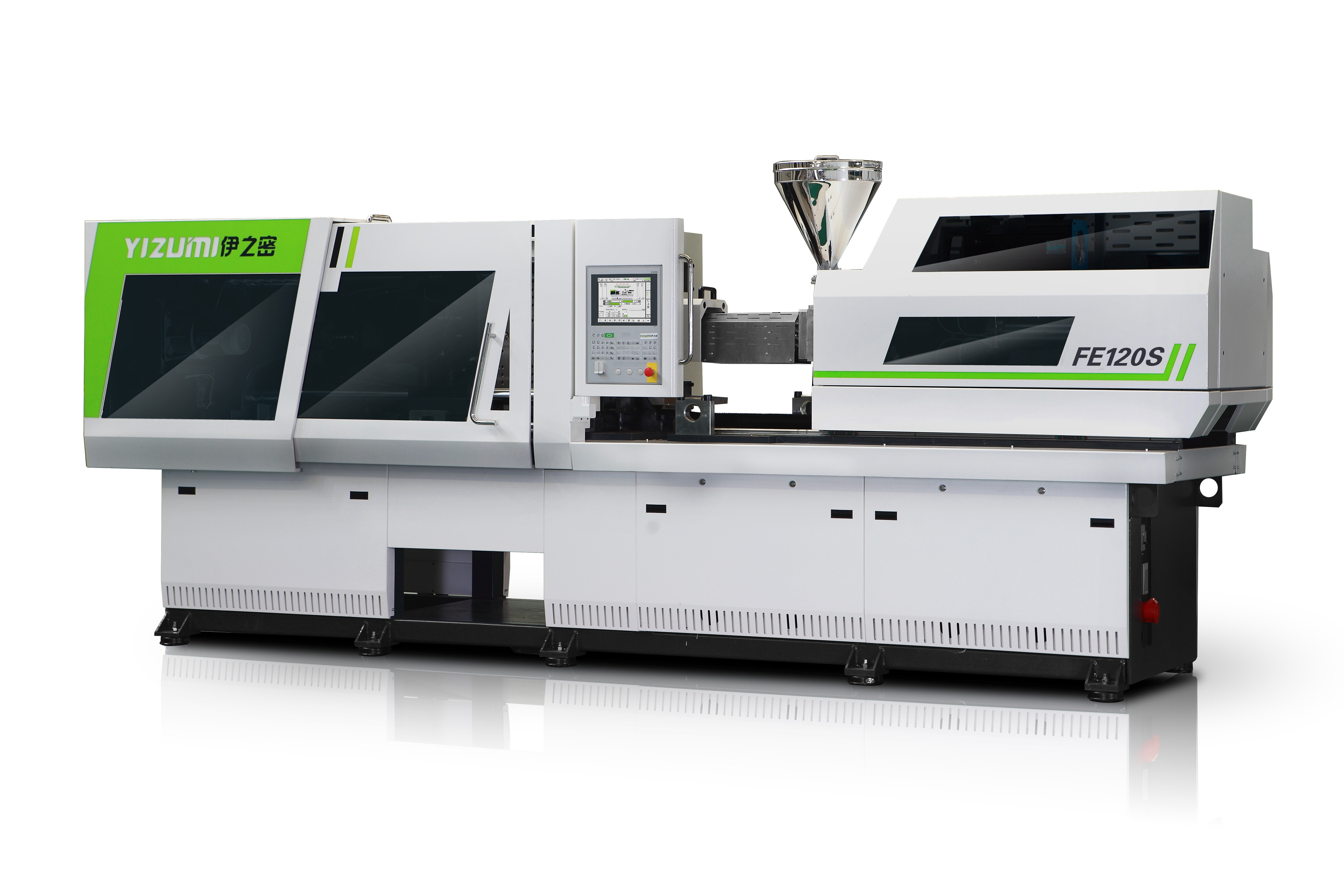

Having compared with many other brands of all-electric injection molding machine, the company eventually chose Yizumi’s FE120 high-speed all-electric machine, which, equipped with the Keba controller and the Phase control system, has upgraded the electric control system, designing, and software algorithm, thus realizing an injection velocity of 500mm/s and ensuring accurate shot end control and machine stability. So far the FE machine has been widely used in such fields as 3C, medical health and fast consumption product etc. to produce cell phone screen borders and thin-walled parts and so on.

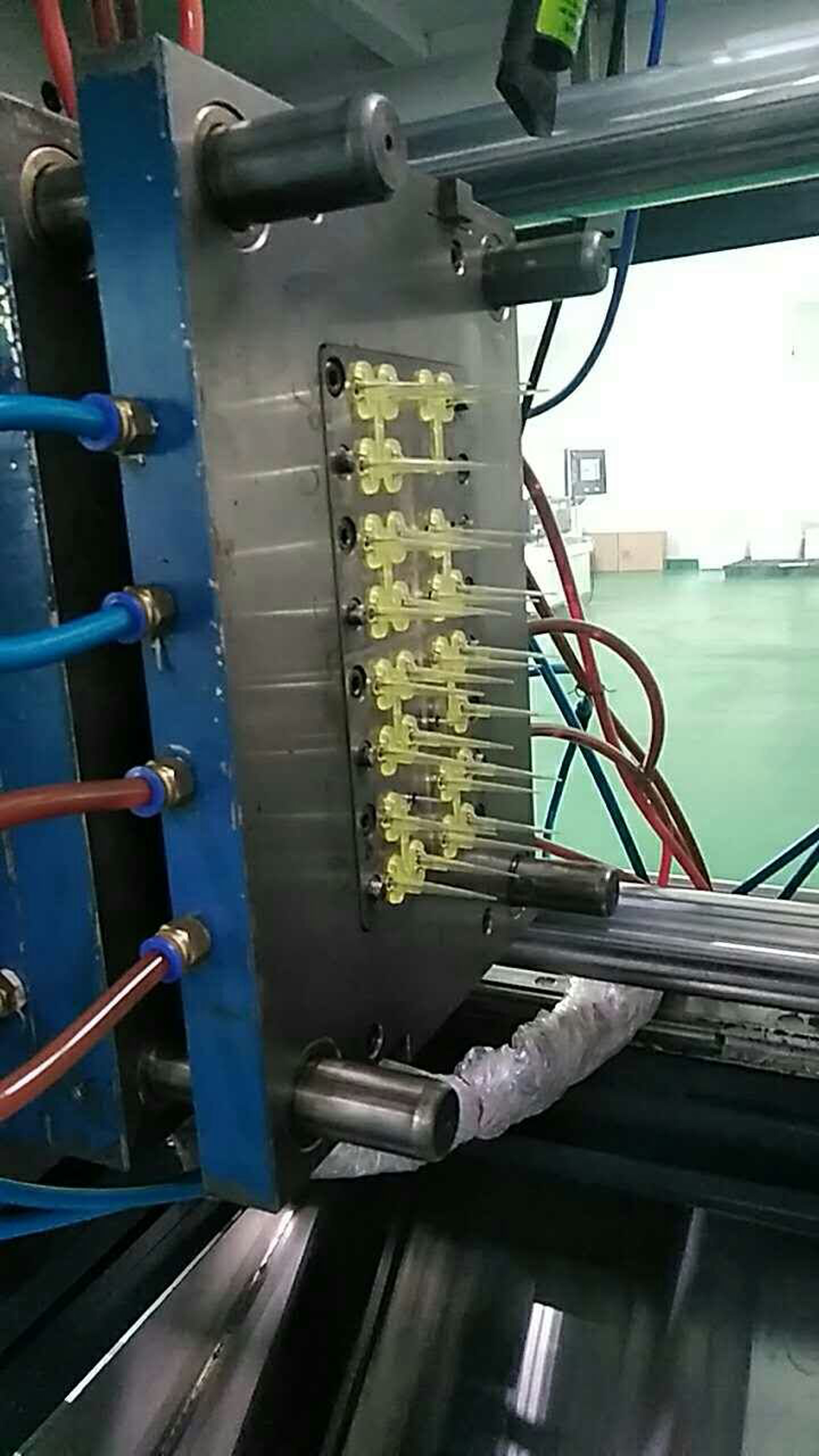

With advanced polypropylene raw material and precise 64-clavity mold, the FE120 high-speed all-electric injection molding machine can produce about 460,000 thin-walled pipette tips a day with cycle time of 12 seconds and injection pressure of no more than 80MPa and a repeatability of 0.05mm. The products are all qualified with no one deformed or distorted after 24 hours. Since October 2016, the FE120 high-speed injection molding machine has been in operation for six months; it meets all of the requirements of the company.

The successful application of Yizumi’s all-electric machine has enhanced the medical plastics manufacturer’s confidence in expanding its future production. This year, we will continue to enlarge the dust-free workshop and buy more FE high-speed all-electric injection molding machine to support more production lines of pipette tips, said one of the leaders of the company.