Functions Upgrade for Smart Production

Abstract:

Functions Upgrade for Smart Production

In the face of the outbreak of COVID-19, recruitment difficulties, scarcity of skilled workers, and homogeneous competition in the industry, plastic processing enterprises are accelerating the process of smart manufacturing to reduce reliance on labor and improve risk resistance capacity.

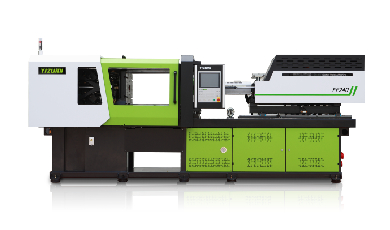

FF series electric injection molding machine, one of the YIZUMI’s leading machines, has long been devoted to breaking the technical bottleneck in smart injection molding systems, to continuously meet customer’s new demand for smart machines and intelligent injection molding systems.

This year, YIZUMI brought the FF series electric injection molding machine equipped with a number of smart functions to the CHINAPLAS, presenting the smart machine charm. YIZUMI also demonstrated two solutions at site——the 64+64 stack mold solution for top and bottom USB data cable and the automation solution for headphone charging case, to allow customers to have a multifaceted experience on smart injection molding processes.

SCFM Smart Clamping Force Management

The SCFM system independently developed by YIZUMI is a new upgrade based on the auto adjustment mode according to the clamping force. The SCFM system offers functions such as real-time measuring, smart recommendation, no-stop adjustment, and auto-holding to assist operators controlling the injection molding machine in a quick and easy way. With the help of SCFM system, injection molding machine can produce qualified products according to the reasonable clamping force set by the injection molding process.

·Real-time measuring: Directly view the clamping force in real-time through PC interface;

·Smart recommendation: Intelligently recommend the most appropriate clamping force to customers through online equipment monitoring;

·Auto-holding: Clamping force can be maintained for an extended time due to dynamic correction during machine operation.

·No-stop adjustment: Directly input the value of the clamping force on PC screen. The machine will adjust the clamping force within two to three trials to save operating time;

SIC Smart Injection Control Technology

Through a software-controlled algorithm, the SIC technology of the FF series electric injection molding machine can control the injection end positionto improve injection precision.

·Improve the stability of product weight and the product dimensional accuracy;

·Effectively solve the imbalanced filling issue during injection molding: Eliminate short shot, flash and improve the balance of filling;

·Control peak pressure: Reduce the internal stress of product. Eliminate deformation and differences in optical characteristics caused by imbalanced internal stress;

Automatic Quality Sorting System

Specification range of qualified products is determined by key process parameters, such as injection and pressure holding time, injection starting position, minimum buffer, injection peak pressure, etc. thus providing guidance for automatic quality inspection. It can identify and distinguish qualified and non-qualified products to avoid defects being mixed into the qualified product batch.

The automatic quality sorting system acts as the inspector who can mitigate the product quality risk by detecting equipment issues in a timely manner during the process.

Two-stage Clamping + Low -Pressure Injection

Mold close with a low clamping force firstly. When plastic melt reaches certain position, mold closing shall be enhanced to reach the pre-set clamping force until finished molding process.

This function can not only optimize the minimum wall thickness of products made by injection molding machine of the same clamping force, injection pressure and speed, but also effectively eliminate the internal stress of the product and reduce the required injection speed and the maximum injection pressure.

Solutions:

64+64 Stack Mold Solution for Top and Bottom Case of the USB Data Cable

With the above smart functions, combined with the stack mold technology and the automated sprue separation technology, FF240 electric injection molding machine demonstrated the solution for the 64+64 top and bottom case of the USB data cable

In this solution, though the top and bottom cases of the USB data cable have different designs and weights, YIZUMI has managed to achieve the production with two molds in one machine at the same time, improving the productivity significantly.

More importantly, FF electric injection molding machine has the advantage of high injection speed and stability, smart auxiliary equipment, which effectively improve the qualified rate and output efficiency, increase the investment income of customers and create the maximum value for customers.

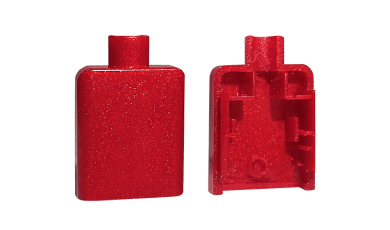

Product:Top Case of the USB Data Cable:

Number of cavities:64+64 stack mold

Material:Spray-free ABS

Part size(L×W):: 22×15mm

Part weight:0.6g

Wall thickness: 1.2mm

Cycle time:15s

Integrated Solution for Headphone Charging Case

As one of the key displays at the smart manufacturing tech zone of the CHINAPLAS 2021, FF120 electric injection molding machine is equipped with SCFM system and SIC technology, as well as functions such as sprue removal, punching and automatic packing to demonstrate the automated solution for the headphone charging case.

Product: Headphone Charging Case

Part weight: 47g

Wall thickness: 1.8mm

Material: ABS

Cycle time: 30s