From Particles to Oil Pollution, This Medical Clean Production Solution Has Considered for You

Abstract:

From Particles to Oil Pollution, This Medical Clean Production Solution Has Considered for You

Filtering infusion apparatus, syringe, pipette and other medical consumables have higher and higher requirements for clean production environment. However, plastic processing easily brings problems of oil pollution, particle volatilization, air turbulence…, reducing products’ cleanliness. How to avoid these problems during production? Yizumi all-electric injection molding machine provides clean and environmental production solution, considers thoughtfully for you, from particles to oil pollution, air turbulence, heat emission, etc.

The following introduction is about how Yizumi’s all-electric solves these clean problems one by one

No Hydraulic Oil Leak

Yizumi’s electric injection molding machine drives by electrical motor and ball screw, without hydraulic oil, completely removes the oil-leaking risk.

Reduces Oil Pollution for Lubrication

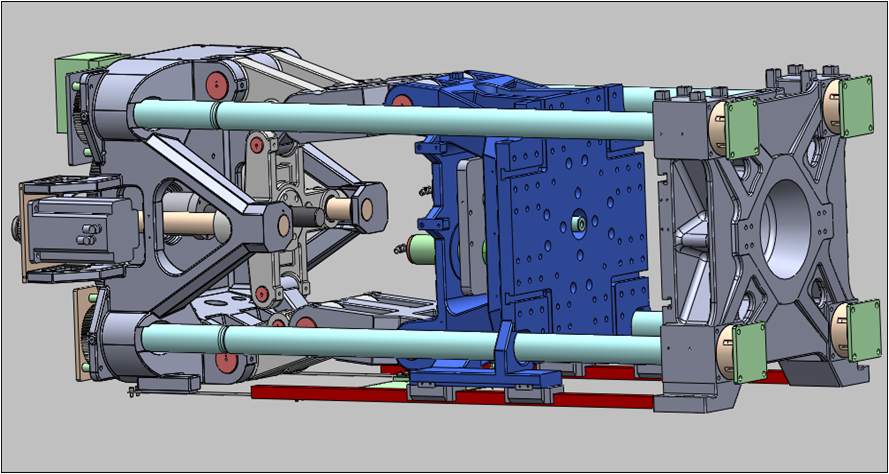

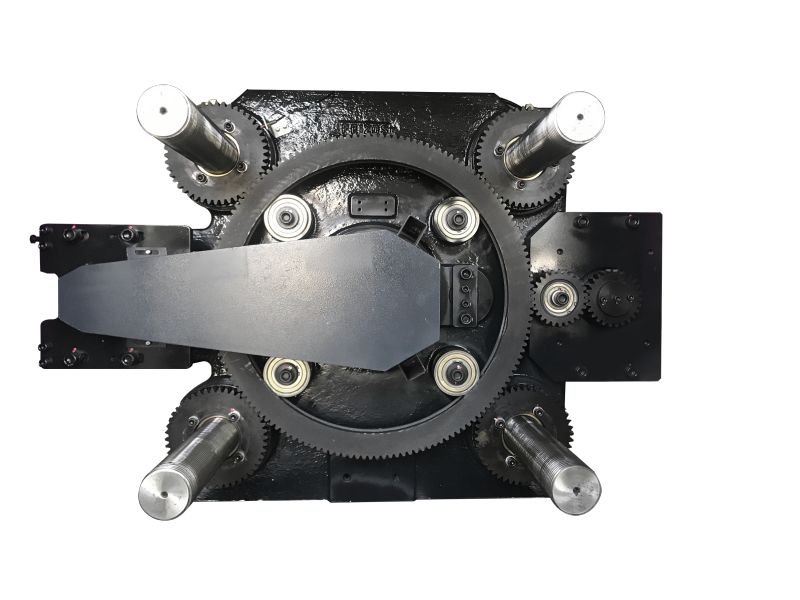

·The clamping unit adopts the TBF (Tie Bar Free) structure, with low mechanical friction force, energy consumption and failure rate;

· Non-contact between moving platen and tie bar and the molding area doesn’t need lubrication, which is clean and environmental, causing no product and environment pollution;

·Injection unit is supported by linear guide, all the mechanical motion adopts rolling friction on the linear guide to reduce oil pollution.

Reduces Oil Pollution

·Built-in servo pump could quickly apply mold with termination and core pulling needs, integrating with the whole machine control system. Its respond speed is faster than asynchronous motor, with no external space, reducing oil pollution and breakdown on site;

Reduces Particles Volatilization

·Lubricating grease could effectively decrease the volatilization of lubricating oil, reducing oil pollution;

·Drops the surface temperature of barrel unit;

·Installs closed design, reduces the contact between moving parts and air, avoids particles from motion and friction diffusing to the air;

Reduces Air Turbulence, Avoids Dust Emission

·Fan adopts commitment control, it operates for cooling when the temperature of servo motor is too high and stops when the temperature is low, reducing the operating frequency.

·Adopts high power motor, ensures that the temperature of the motor isn’t too high, replacing fan cooling, reducing air turbulence.

Reduces Heat Emission

·Adopts far-infrared heating band, reduces the surface temperature of barrel unit, reducing the electricity consumption for air-conditioner and air turbulence on workshop, improving the workshop environment effected by barrel unit heating.

Optimal Space Layout

·Electric injection molding machine could install large clamping unit with small injection unit, which is more suitable for medical mold production requirement. Its small coverage area could better satisfy the requirement of clean workshop matched with robotic arms and auxiliary equipment.

Including mechanical design, configuration and producing environment, Yizumi electric injection molding machine considers clean production requirement of medical appliances, avoiding the pollution problem to the largest extent.

With the gradual tightening of national supervision for medical consumables, clean workshop has become an essential part of factory’s quality system. Yizumi cooperates with medical consumables factories, provides production solution with high cleanliness and efficiency, readies for the new round of industry challenge.