【DMP Preview】IMD Mobile Phone Back Frame Production Line for 5G Era

Abstract:

【DMP Preview】IMD Mobile Phone Back Frame Production Line for 5G Era

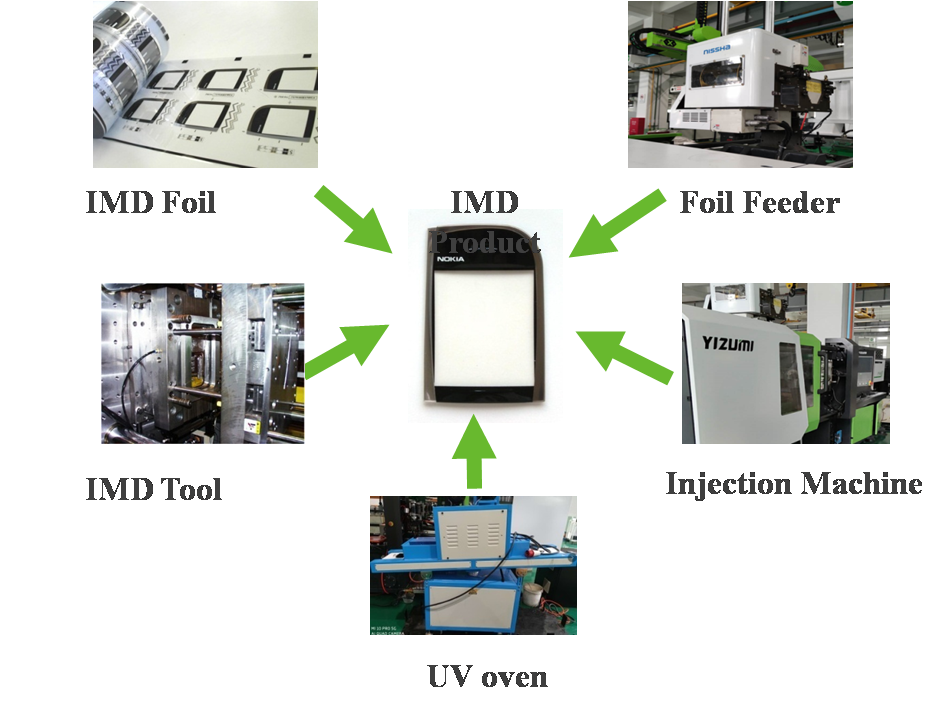

With people chasing new phones because of 5G technology, how will injection molding factory prepare for this opportunity? Combined with in-mold decoration molding process, YIZUMI electric injection molding machine launches 5G mobile phone back frame solution to effectively satisfy automatic production needs of 5G mobile phone back frame with multifunctional surface. This impressive solution will shine at DMP 2020 exhibition. (November 24th -27th, Shenzhen World Exhibition & Convention Center)

As an internationally popular decoration technology, IMD (in-mold decoration) technology produces products with transparent and hardened foil on the surface, paint layers in the middle as well as a plastic layer on the back. Besides, the middle printing ink makes abrasion-resistant, scratch-resistant and unfading products possible.

Value Advantages

Stable and precise: the product weight repeatability reaches 0.3%;

High injection speed and injection pressure: injection speed has improved by 2-3 times, plasticizing speed has improved by 2 times, mold open and mold close speed have increased by 30%. Synchronized ejector movement and plasticizing can be realized;

Clean and environment-friendly: Non-contact tie bars and ball screw driving reduce grease pollution and leakage;

Smart injection: SIC Smart Injection Control solves the uneven filling problem of multi-cavity molds; SPH Smart Clamping Force Retention System automatically remains clamping force during operation.

* The Data above were acquired by testing in the factory, only for your reference. The specific data please accord to the actual equipment.

Create more possibilities for customers is our aim! Based on IPD process, YIZUMI has developed ranges of electric injection molding machines such as FE series electric injection molding machine, FF series electric injection molding machine, HE series electric-hydraulic hybrid injection molding machine and has mastered core technologies including electric injection, precise plasticizing control, precise control of mold opening and closing, and injection compression molding. Our flexible product configuration solutions can be applied to different-tonnaged machines, of which clamping force ranges from 60T to 460T. We provide customers with solutions in various industries. So far, YIZUMI electric injection technologies and products are widely used in sophisticated electronics, medical treatment, packaging, automobile parts and other industries.