D1 Series: An Innovation in Trend of Large Two-platen Machine

Abstract:

D1 Series: An Innovation in Trend of Large Two-platen Machine

In recent years it has become a trend that small injection molding machines are made all-electric, while large machines are developing towards two-platen design. Domestic two-platen injection molding machines, as a main force in this trend, have showed increasingly more occupancy in the marketplace. Yizumi, as a rising star in this market, based on the mature application of DP series two-platen machine, has developed a new D1 series two-platen injection machine in line with the proven IPD model and the high technology introduced from Germany.

D1 series is dedicated to leading the trend of large-tonnage two-platen injection molding machines. Centered on customers’ need, the machine is very innovative and much superior to large toggle-clamp machines in terms of footprint, efficiency, repeatability of mold opening and closing positions, low pressure mold protection, and equipment maintenance cost, etc. and it has been widely recognized by customers. D1 series machine has good performance in the dry cycle time and stability thanks to its clear market positioning and product value proposition, based on which the R&D team has developed a series of solutions and tests and after two years of improvement and optimization, eventually pushed it into the market.

The technological innovation of the D1 series lies in two core values: fast speed and high stability.

【Fast】 D1 series has made a breakthrough in the dry cycle time and plasticizing efficiency. All movements related to the dry cycle time have been optimized. Mold movements are faster. Tie bar nuts are added with a patented design so as to realize fast synchronous collision-free tie bar locking at a speed of 0.2 to 0.5 seconds. Thanks to the optimum combination of power unit, hydraulic circuit design and control system, each movement D1 machine is highly efficient with extremely short dry cycle time (Euromap 6 dry cycle time of 1400D1 machine is 5.9 seconds), about 50% faster than ordinary toggle machines, also noticeably better than ordinary two-platen injection machines.

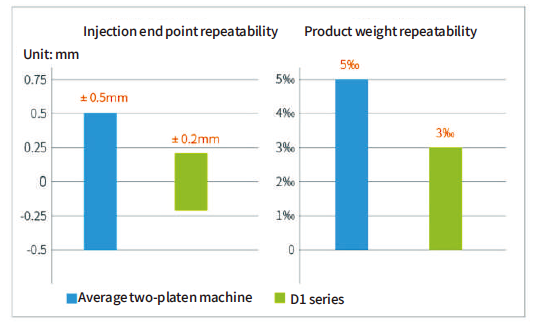

【Stable】 According to customers’ feedback, the indicators of stability in their use agree with those in tests. For example, the repeatability of mold-open end position and injection end position is kept within ±0.2mm, and the part weight repeatability won’t be more than 3‰ to ensure maximum stability of the machine in operation and the highest QC passing rate of molded parts. Besides, the mold is protected in low pressure by adapting the "SmartClamp" control technology where the system decelerates in advance. Mold protection has also been more sensitive and reliable; even three pieces of A4 paper can trigger the alarm and protect the mold from damage. This can dramatically reduce the failure rate and increase the stability.

The D1 series has set out in large two-platen injection molding machine evolution, and will for sure achieve good performance based on the in-depth knowledge of the global customer needs, market-oriented innovative service idea, introduction of advanced technology and technical innovation.