【Customer Story】Zhongqi Die Casting: Focus on the field of electric bicycle

Abstract:

【Customer Story】Zhongqi Die Casting: Focus on the field of electric bicycle

In recent years, two-wheeled electric bicycles have gradually replaced motorcycles, becoming daily travel vehicles for most people, and are widely used in commuting or short-distance travel. According to the data of CCA, in 2018 the annual output of domestic two-wheel electric vehicles exceeded 30 million, and the market demand continues to grow.

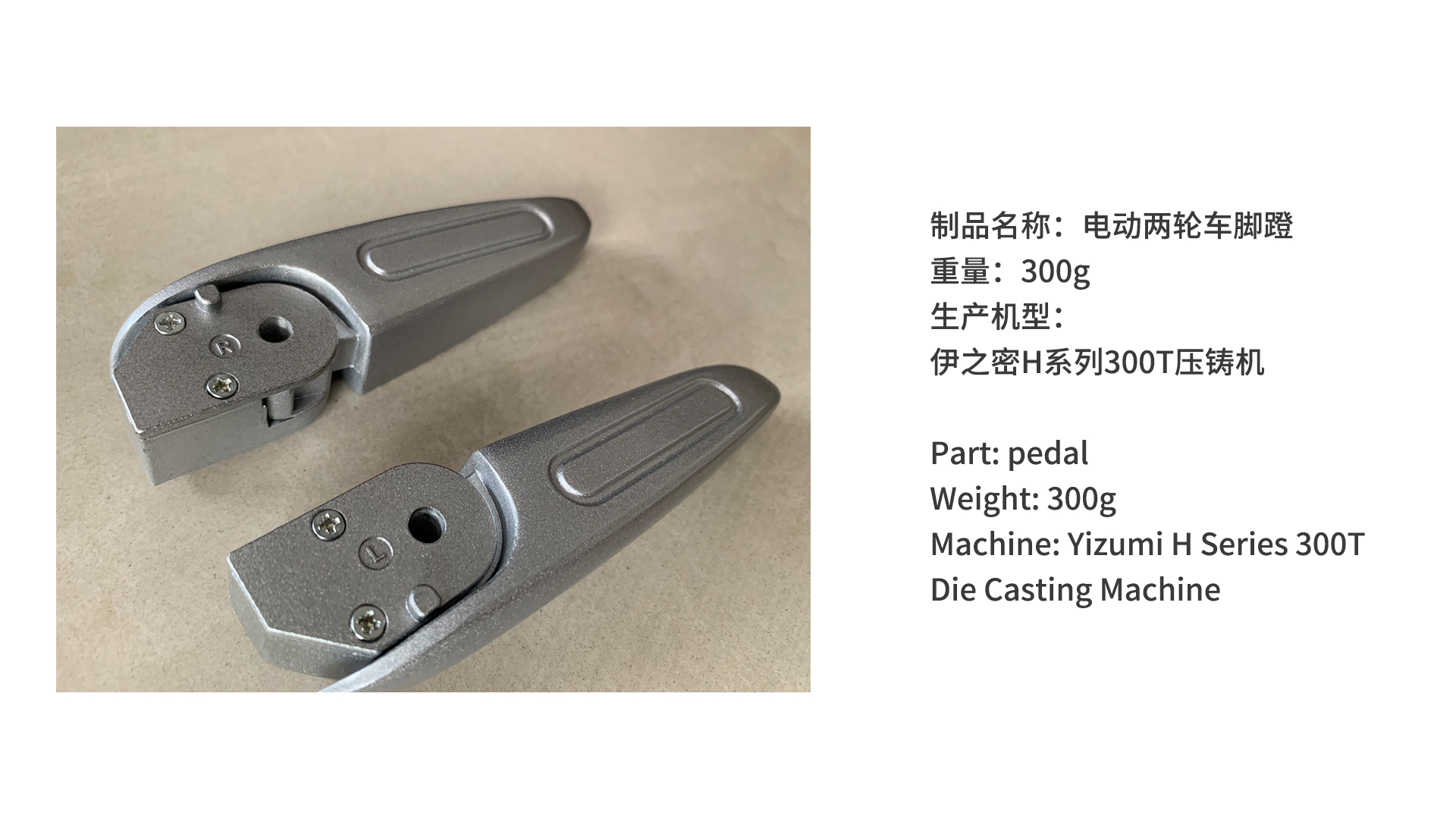

Focusing on the development momentum of two-wheeled electric vehicles, Taizhou Zhongqi Die Casting Co., Ltd. (hereinafter referred to as “Zhongqi Die Casting”), which was established in 2000, has gradually shifted its business from motorcycles and scooters to two-wheel electric vehicles to design and manufacture molds and various aluminum alloy castings. There are hundreds of varieties of products including rear shelf, rear fork, pedal, connecting plate, single support and other aluminum alloy parts. Customers are mainly domestic well-known electric vehicle enterprises, including Aima, Yadea, Sunra, Luyuan, and NIU etc., account for 25% of the aluminum alloy parts market for electric two-wheelers in China. It can be said that the company is an invisible champion in the field of aluminum alloy parts for electric two-wheelers.

How can Zhongqi Die Casting be recognized by well-known enterprises in the industry? General Manager Liang Yongxing concluded that the company's core strength lies in its variety of products, high quality and strong development capabilities.

First of all, there are hundreds of varieties of Zhongqi die-casting, covering almost all aluminum alloy parts of two-wheel electric vehicles, and insisting on independent research and development, tightly controlling product quality from mold design, and introducing advanced processing and manufacturing equipment, investing more than CNY20 million(approx.. USD2.9 million). The company also has a R&D team of more than 20 personnel, and can quickly respond to customer requirements, develop more than 100 sets of molds per year.

Taking the newly developed aluminum alloy frame of electric vehicles as an example, Zhongqi Die Casting actively participates in the pre-research of new models of customers, and newly designs the parts that have been welded by steel, develops the molds, and integrally forms them by die casting. This not only meets the demand for performance, but also reduces part weight.

In order to ensure the quality of the products, Zhongqi Die Casting chose to cooperate with Yizumi, and successively purchased 15 sets of Yizumi H high end series die casting machines (300 tons - 1250 tons). Liang Yongxing said that the product needs to be drilled later, and the low compactness of the product will lead to scrapping of the product. Yizumi die casting machines have been stable and reliable for many years, and the product has no porosity and sand hole, and the pass rate is 99%.

After years of development, electric two-wheelers have entered the development stage of intelligent, lightweight and high-end. With the implementation of the new national standard in 2019, the electric vehicle industry is expected to usher in a new round of reshuffle.

In order to maintain the competitiveness of the industry in future development, this year, Zhongqi Die Casting increased investment, established a new plant measuring 20,000 square meters, and invested in a new die-casting automatic production line, which not only were equipped with multiple sets of Yizumi die-casting machines, but also automated part removal, spray robots, automatic molten aluminum transportation line, and product conveyor, etc. In this way, only one worker is needed to operate every 1 to 2 die casting machines, which greatly saves labor costs, and the overall production efficiency is expected to increase by more than 20%.

Liang Yongxing believes that in the new round of competition, in addition to maintaining stable quality and improving production efficiency through automation, enterprises can also achieve better cost advantages. In addition, Zhongqi Die Casting has gradually branches into new areas, such as automobiles, shared bicycles, 5G base stations, research and development of new products, and fostering new growth sectors. The company's new plant was officially put into operation in July, and the annual output value is expected to reach 160 million Yuan(approx. 23 million USD).

<<< Slide left or right >>>

Customer Reference:

Liang Yongxing, General Manager of Taizhou Zhongqi Die Casting Co., Ltd.