【Customer Case】 Changchun LIJIA: Casting of Gearbox Housing for Heavy - Duty Truck with YIZUMI DM4500H Fully Automated Die Casting Cell

Abstract:

【Customer Case】 Changchun LIJIA: Casting of Gearbox Housing for Heavy - Duty Truck with YIZUMI DM4500H Fully Automated Die Casting Cell

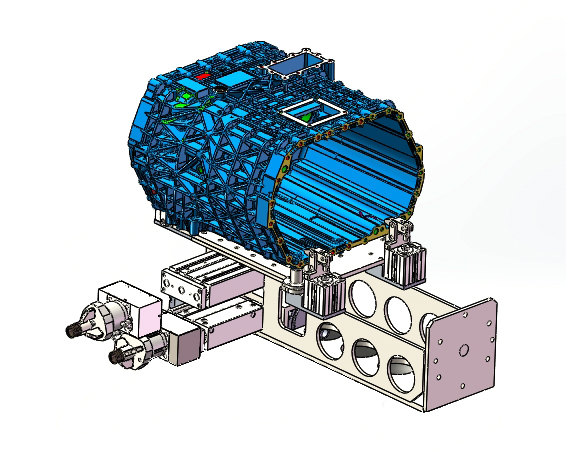

Since Changchun LIJIA acquired YIZUMI DM4500H fully automated Robotic die-casting cell in year 2019, YIZUMI has successfully completed the delivery and debugging of this heavy duty die casting machine complete with Automation cell. Machine assigned for casting of gearbox housing for heavy-duty trucks successfully commissioned in March this year. This is the biggest tonnage die casting machine cell in LIAJIA.

The entire system could complete the full production process automatically including spraying for die release, product extraction, integrity inspection, overflow removal, cooling, deburring & stacking. This System has overcome many technical difficulties with challenges as below:

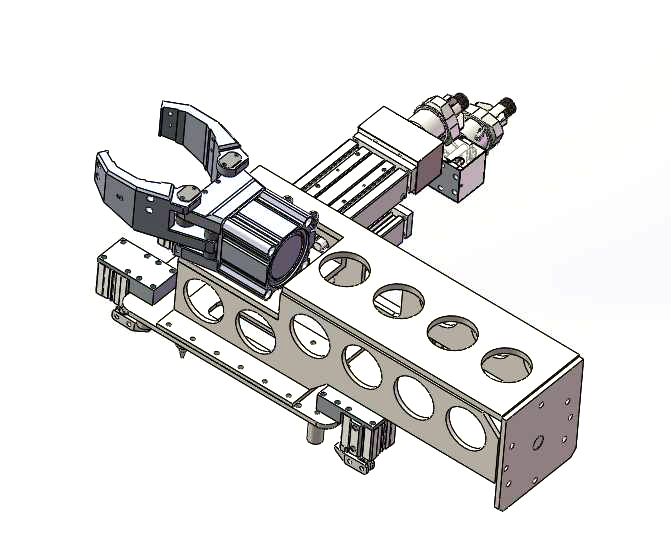

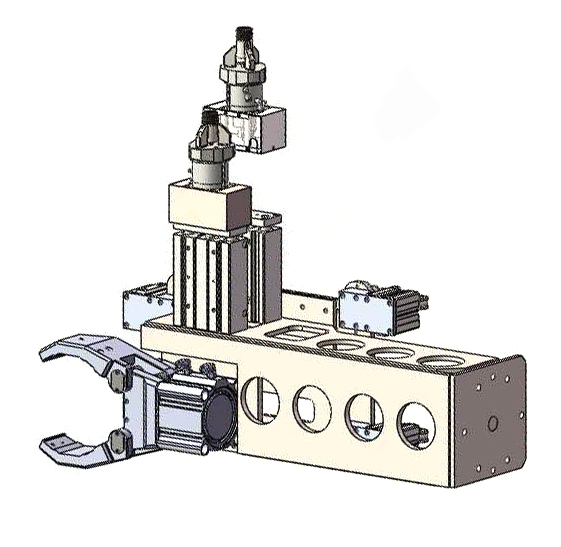

Multifunctional demands of removal robot

1. The gearbox housing of heavy-duty trucks is large & heavy. Result with great challenge for the gripper with stability during extraction. Any negligence during extraction by grabbing the sprue may result falling of the product. It may cause deformation or damage to the sprue and product. This also result with interruption to continue the subsequent process such as marking and sprue removal.

2. Insert with two small rings to be placed on both movable & fixed platen. The insertion position for each fixed point are different. This may result with low production yield if not inserted in place.

3. After the gate removal, the product will have to undergo deburring and stacking. Thereafter, the robot needs to extract the product once again after the gate removal.

Special-shaped mold with effective spraying demands

Special-shaped molds with complex structure & deep die cavity. The ordinary spray head with low spray pressure could not accomplish the task. To achieve an even and improve efficiency of spaying function while reducing unnecessary movement is a tough problem.

Special spray arm with combined structure is specially designed by YIZUMI for product housing which reduces the unnecessary movement in the coating operation and allows appropriate amount of expansion with multiple spray heads, to achieve an effective spray distance of more than 500 mm. The connection of control valve and spray arm ensures the flow of atomized gas and air blow. Through fast response, it improves the spray frequency and quality effectively, optimizes the atomization effect, and allows an even surface coverage of the mold release agent, resulting in lower failure rate.

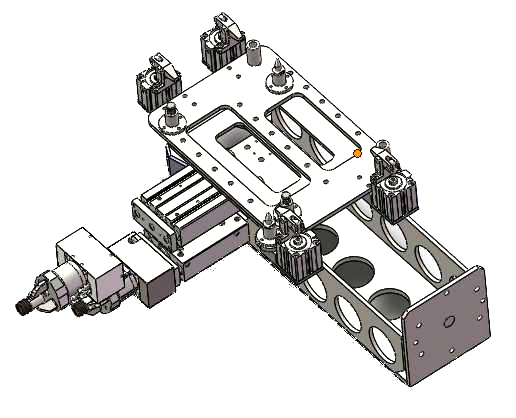

Complicated deburring demand

For burrs on the parting surfaces and in deep cavity, an electrical spindle or optional pneumatic spindle is available with a flexible free-floating range of 360° ± 15 mm to remove sharp burrs in special shaped holes, round holes, and other less accessible areas. It can also polish off the gate residuals for a better smooth surface and higher production yield.

Automatic stacking and handling demand

In vast majority of die-casting workshops, it is common to handle such die-cast clutch housing manually, which is time-consuming and labor intensive. When the casting weight is too heavy, manual handling becomes impossible. As a result, the application of fully automated equipment is imminence.

The custom-made cylinder stacking automated workstation designed by YIZUMI is equipped with integrated grip-sucking claws which is able to determine the state of workpiece extraction and add divider during the stacking. The double-layer stacking processes are simplified into one single grip. Depending on the products and the types of stacking, the system has an open stacking process package that allows you to build circled or array stack modeling to save manpower.