【Customer Case】Annual Production Capacity More Than 6000 Tons- PROFESSIONAL: Reach higher with PROFESSIONAL

Abstract:

【Customer Case】Annual Production Capacity More Than 6000 Tons- PROFESSIONAL: Reach higher with PROFESSIONAL

Pursuitof Quality, Market Driven

Building up a strong Corporate Reputation in the Industry

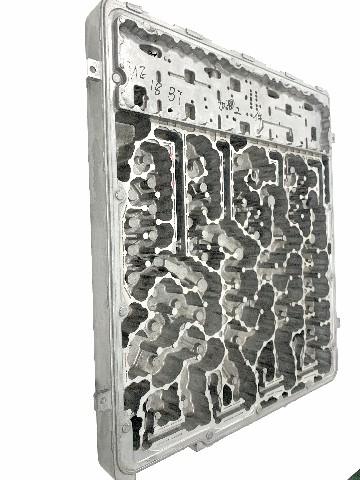

Founded at the beginning of 2017, PROFESSIONAL started the operation in June of the same year, primarily producing valve body and precision die-casting components for electrical appliances, auto parts, lighting fixtures, and telecommunications equipment. It is an innovative enterprise specializing in design, R&D, smelting, aluminum die-casting, high-precision machining, and mold design and manufacturing.

“Inthe past, quality tells you how good the enterprise is. Today, qualitydetermines whether the enterprise can survive.” KunguangLi is well aware that choosing the right die casting machine with goodperformance is the reliable assurance of the high-quality die castings.

Onthis account, PROFESSIONAL has increased its investment and acquireddie-casting equipment from YIZUMI several times. As of today, six die-castingproduction lines consisting of YIZUMI’s 650T, 1650T, 2000T, and various other die-castingmachines are working smoothly in the factory. In addition, these lines areequipped with advanced spectrometers, X-ray flaw detectors, three coordinatesmeasuring instruments, and other precision testing equipment and tools,providing a sound quality assurance system for the products.

“From the general-purpose aluminum andmagnesium die-casting machine in earlier years to the H series heavy-dutydie-casting machines today, I have witnessed the evolution of YIZUMI’sdie-casting machine family.” Regarding the cooperation with YIZUMI, Kunguang Lisaid, “YIZUMI machines offer a robust and reliable performance with low failurerate. Their clamping system also provides great strength, stiffness, anddurability. The injection system maintains excellent stability andrepeatability which could meet the production needs.”

After four years of development, PROFESSIONALhas become more skillful with aluminum alloy production technology. In themeantime, the enterprise also introduced ultra-low speed, vacuum, local squeezing,and other advanced die-casting mold technologies to meet production capacityneeds.

Today, PROFESSIONAL has made its name in the die-casting industry for its high-quality and efficient production of aluminum alloy die casting products. Relying on its “Professional” dedication, the company continues to grow, with its annual output of aluminum alloy die-casting products now exceeding 6000 tons.

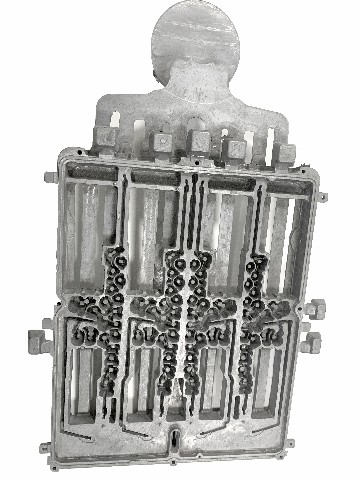

Automotive Parts

5G Die-casting Parts

New Energy Vehicle Parts

Boostprofits by cutting costs and enhancing productivity

Becoming an Industry Leader

The market competition in the futureis becoming more fierce and complex. How to maintain core competitiveness underthe new circumstances has become a great challenge for enterprise managers.

Through scientifically based management, improvement of product quality, and reduction of production costs, PROFESSIONAL is able to provide customers with the best quality service at preferential prices which in turn allows the customers to have a price advantage on the market for more purchase orders. PROFESSIONAL’s business goal is to achieve a “Win-Win” result.

How to reduce the production costs? AsKunguang Li said, in today’s die-casting industry, the time to make windfallprofits relying only on hardware advantages is long gone. You have to find yourprofit point through scientifically based management.

For instance: in die-casting production, each die-casting process .consists of various process steps. Establishing each step with a stable process is a key to a high quality die casting production.

A well designed Quality Management System with a detailed Control Plan will ensure that process inconsistencies or rejects may be detected early in the value adding process. This will ensure a cost efficient overall manufacturing performance.

Also, in the die design, manufacturing and heat treatment processes, if you put every step under control, you can ensure both the service life of the mold and the quality of the die-casting products to save production costs.

“Our company is continuously deepening and extending markets.” said Kunguang Li, “As long as we have the regional market and retain the key customers, our sales are guaranteed.”

Speaking of the vision of the enterprise, Kunguang Li is full of confidence: "As we rely on our strong technical background to drive the market, we believe that it won’t take long for PROFESSIONAL to become a rising star in the die-casting industry as an innovative leader.”